Key Specifications / Features

Model No.: SJ-PCV-08S Hits: 406

Detail Information

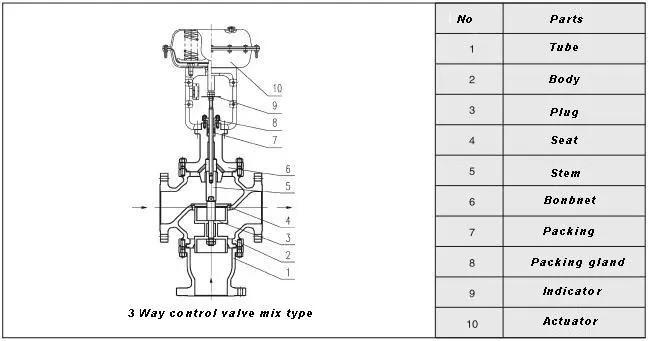

Materials of main parts

| Name | Texture of material |

| The valve body | ZG230-450、ZG0Cr18Ni9 |

| Valve seat | 0Cr18Ni9, 0Cr18Ni9+PTFE, 0Cr18Ni9+ division Chatterley |

| The valve stem | 0Cr18Ni9、2Cr13 |

| The push rod | 0Cr18Ni9、2Cr13 |

| Spring | 60Si2Mn |

| Bellows | 0Cr18Ni9 |

| Corrugated diaphragm | Clip reinforced nylon fabric nitrile rubber |

| Film cover | A3、0Cr18Ni9 |

| Shim | 0Cr18Ni9, graphite spiral wound gasket (V6590), F4 |

| Filler | PTFE, flexible graphite |

The main technical parameters of the three-way valve

| All diameter. | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| Seat diameter mm | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| Rated KV | 8.5 | 13 | 21 | 34 | 53 | 85 | 135 | 210 | 340 | 535 | 800 | 1280 | 1960 | 2560 |

| Nominal pressure(MPa) | 1.6、2.5、4.0、6.4 | |||||||||||||

| Trip(mm) | 16 | 25 | 40 | 60 | 100 | 130 | ||||||||

| The effective area of the film Ae (cm2) |

280 | 350 | 560 | 900 | 1400 | |||||||||

| Signal range KPa | 20-100、40-200、80-240 | |||||||||||||

| Air pressure MPa | 0.1-0.4 | 0.4-0.7 | ||||||||||||

| The inherent flow characteristics | Linear, equal percentage, quick opening | |||||||||||||

| The inherent adjustable ratio | 30:1 | |||||||||||||

| The leakage class | III、IV | |||||||||||||

| Flange size | According to JB/79. (2) _94, HG20592_97, GB, ANSI, JIB, DIN and other standards | |||||||||||||

| Body material | WCB, 304, 316, WC6, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||

| Valve material | 304, 316, 420, nickel, titanium, Hastelloy, Monel etc. | |||||||||||||

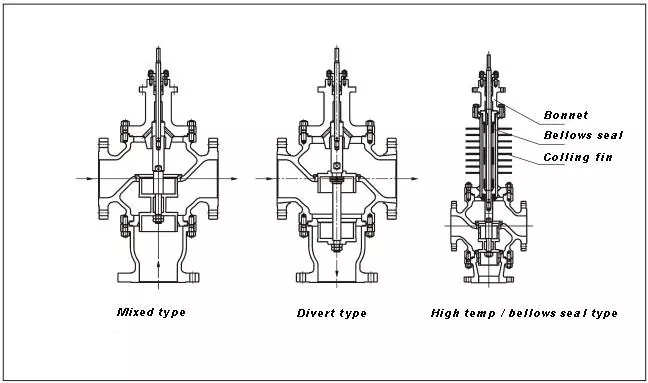

| Working temperature ℃ | -40~+230 ℃ (room temperature), +230~+450 ℃ (temperature), +450~+560 ℃, -40~-196 ℃ (high temperature) (low) | |||||||||||||

| Series type | At room temperature, medium temperature, low temperature type. Bellows seal type, jacket type heat, regulating off type | |||||||||||||

Main performance index

| Serial number | Project | The performance index | ||

| Not with a locator | with a locator | |||

| 1 | basic error(%) | ±5 | ±1 | |

| 2 | The return difference <(%) | 3 | 1 | |

| 3 | The dead zone<(%) | 3 | 0.4 | |

| 4 | Always point bias<(%) | The starting point(%) | ±5 | ±1 |

| Finish(%) | ±2.5 | |||

| 5 | Rated stroke deviation <(%) | ±2.5 | ||

| 6 | Allowable leakage (1/h) | The rated flow coefficient deviation< (%) | ||

| 7 | The rated flow coefficient deviation<(%) | ±10 | ||

| 8 | The inherent flow characteristics | To meet the requirements specified in IEC534-1 and GB/T4213-92 slope deviation in | ||

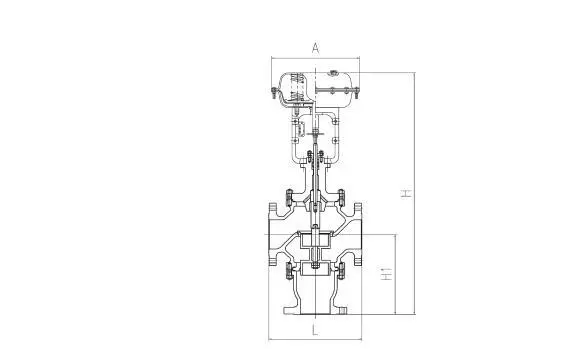

| DN(mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| L | PN1.6MPa | 185 | 200 | 220 | 250 | 275 | 300 | 350 | 410 | 450 | 550 | 670 | 700 |

| PN4.0MPa | 190 | 210 | 230 | 255 | 285 | 310 | 355 | 425 | 460 | 560 | 740 | 803 | |

| PN6.4MPa | 200 | 200 | 240 | 265 | 295 | 320 | 370 | 440 | 475 | 570 | 752 | 819 | |

| H1 | 135 | 152 | 165 | 180 | 200 | 220 | 222 | 265 | 322 | 362 | 508 | 563 | |

| A | 280 | 360 | 470 | 580 | |||||||||

| H Normal atmospheric temperature | 702 | 718 | 795 | 830 | 1067 | 1080 | 1094 | 1293 | 1321 | 1400 | 2065 | 2151 | |

| H Medium temperature | 832 | 818 | 925 | 960 | 1214 | 1243 | 1257 | 1492 | 1520 | 1597 | 2340 | 2432 | |

| Weight (PN64 at room temperature) | 40 | 45 | 60 | 65 | 100 | 125 | 150 | 250 | 290 | 450 | - | - | |

When ordering, please fill in "specification" or indicate the following contents:

One, if the order has not selected models, please provide the parameters are used to send us your

1, nominal diameter, nominal flow in coefficient Kv

2, the fluid properties (including the nominal pressure, temperature, viscosity and pH value "

3, the valve action form (gas closed or gas - Open)

4, flow at

5, in front of the valve, the valve pressure

6, valve body, broad core material

7, the input signal

8, with the attachment, the attachment type, so that we can correct for your selection.

Two, special requirements

1, special inspection

2, complete degreasing, water treatment;

3, no copper processing;

4, special interface, piping;

5, the use of vacuum conditions;

6, specify the color of the coating

7, special medium (gas, chlorine, nitrogen)

8, the use of stainless steel connections;

-pneumatic-diaphragm-3-way-control-valve.jpg?q=80&fm=webp&s=8c207e46afe5794a453318292c0c1a4b)