Key Specifications / Features

Model No.: SJ-ECV-09 Hits: 65

Detail Information

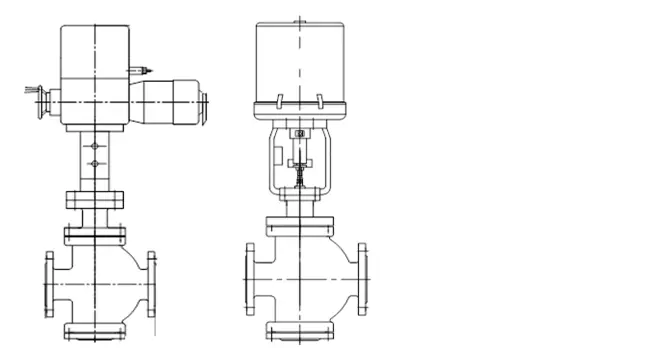

The ZDLN electric double seat control valve is made of 3610L/3810/PSL types electric actuator or intelligent actuator and the double seat valve body. There is servo system in the actuator, so the servo amplifier is not necessary to be equipped, it can be operated with just electricity and input signal. The wire of the actuator is simple, the inside parts of the valve apply with the top-guided structure, which is suitable for the working condition of big differential pressure and big flow rate.

DESIGN PRINCIPLE

The difference between the normal type double seat control valves and cage type double seat control valves are as bellow:

There are two units’ seat, plugs and sealing surface in the normal type double seat control valves, while as for the cage type, it also has two units sealing surface, but it only has one plug. Because of the two flow channel, so the flow capacity (CV) of the double seat control valves are bigger than the single seat type, but the leakage grade is lower than the single seat type, it is usually grade Ⅱ, at most grade Ⅲ.

Same with the cage type control valve, the double seat type also apply with the balanced structure, and the principle is different, the cage type applies with the balanced valve plug structure, while the double seat type applies the balanced structure with the double plug. Compare with cage type, the double seat type are more suitable for the medium with slight impurity or dust. Because of the complex flow channel of double seat control valve, its unbalance force direction will changed with the fluctuation of the differential pressure, so it will vibrate when in the position of small opening, even the serious vibration and noise sometimes.

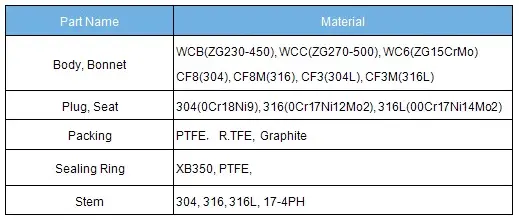

STRUCTURE AND MATERIAL

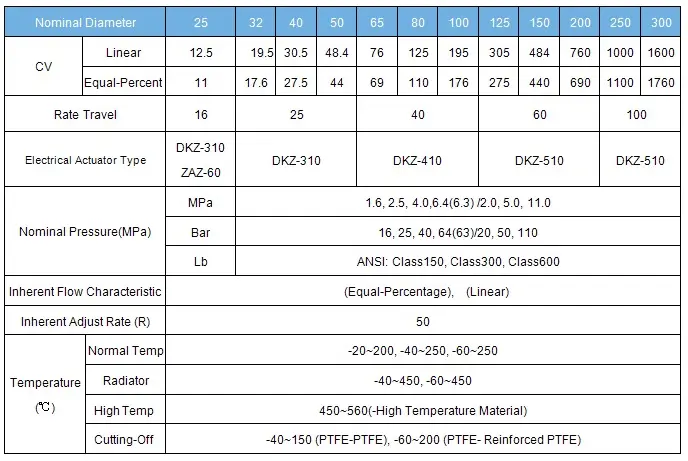

TECHNICAL PARAMETER