Key Specifications / Features

Model No.: SJ-SP-02 Hits: 140

Detail Information

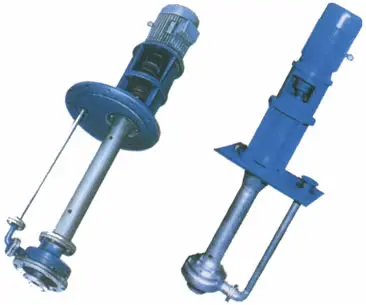

I. Summary for Anti-corrosive Vertical Submerged Pump

Anti-corrosive Vertical Submerged Pump

An FY series anti-corrosive vertical submerged pump is one of single-stage single-suction long-shaft submerged centrifugal pumps. Its marks, performance points and dimension of its flange are designed according to the International Standard of ISO 2858.

Its technical conditions are designed according to ISO5199. It has little volume, high efficiency, power saving and operating reliability compared with former FY series corrosive vertical submerged pumps.

The Remy yielding FY series anti-corrosive vertical submerged pump can not pump corrosive medium which has solid particles and hard materials. The medium temperature varies from 0℃ to 105℃. The heat preservation closed cover and low-temperature hard-wearing guide bearing are used when the temperature of medium is from -20℃ to 0℃; the cooling closed cover and high-temperature hard-wearing guide bearing are used when the temperature of medium is from 105℃ to 180℃. This condition must be stated when the pump is ordered. If medium has little solid particles, the sliding bearing should be outer-lubricated bearing, which shall be stated clearly when the pump is ordered. (Water and other allowed medium whose outer pressure is over 0.2MPa.) The operating pressure is designed at 1.6MPa.

Performance range: capacity: 1.6-2600 m3/h, head: 5-132m

The materials contacting with liquid can be selected as cast iron (H), cast steel, 321 S.S.(B), 1Cr18Ni12Mo2Ti(M), 304, 304L, 316, 316L, 904, Lewmet Alloy 20# according to different medium.

II. Operating Performance Table for Anti-corrosive Vertical Submerged Pump

| Model | Impeller type | speed n=2900r/min | |||||||

| Capacity Q M3/h |

Head H m |

Relative density<1.0 | Relative density<1.35 | Relative density<1.86 | |||||

| Power | Motor model | Power | Motor model | Power | Motor model | ||||

| kw | kw | kw | |||||||

| 25FY-20 | 3.2 | 20 | 1.1 | Y802-2 | 1.5 | Y90S-2 | 2.2 | Y90L-2 | |

| A | 2.8 | 16 | |||||||

| 25FY-32 | 2.8 | 32 | 3 | Y100L-2 | 3 | Y100L-2 | 4 | Y112M-2 | |

| A | 2.8 | 26 | |||||||

| 25FY-50 | 3.2 | 50 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |

| A | 2.8 | 41 | |||||||

| 25FY-80 | 3.2 | 80 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |

| A | 3 | 70 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |

| B | 2.8 | 62 | 4 | Y112M-2 | 5.5 | Y132S1-2 | 11 | ||

| 40FY-20 | 6.3 | 20 | 1.5 | Y90S-2 | 2.2 | Y90L-2 | 3 | Y100L-2 | |

| A | 5.5 | 16 | |||||||

| 40FY-32 | 6.3 | 32 | 3 | Y100L-2 | 3 | Y100L-2 | 4 | Y112M-2 | |

| A | 5.5 | 26 | |||||||

| 40FY-50 | 6.3 | 50 | 5.5 | Y132S1-2 | 7.5 | Y132S-2 | 11 | Y160M1-2 | |

| A | 5.5 | 41 | |||||||

| 40FY-80 | 6.3 | 80 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |

| A | 5.9 | 70 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |

| B | 5.6 | 62 | |||||||

| 50FY-20 | 12.5 | 20 | 1.5 | Y90S-2 | 2.2 | Y90L-2 | 3 | Y100L-2 | |

| A | 11.3 | 16.4 | |||||||

| 50FY-32 | 12.5 | 32 | 3 | Y100L-2 | 4 | Y112M-2 | 5.5 | Y132S1-2 | |

| A | 11.3 | 26.4 | 2.2 | Y90L-2 | 3 | Y100L-2 | 4 | Y112M-2 | |

| 50FY-50 | 12.5 | 50 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |

| A | 11.3 | 41 | 4 | Y112M-2 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |

| 50FY-80 | 12.5 | 80 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |

| A | 11.7 | 70 | 11 | Y160M1-2 | 15 | Y160M2-2 | |||

| B | 11 | 62 | 7.5 | Y132S2-2 | |||||

| 65FY-20 | 25 | 20 | 3 | Y100L-2 | 4 | Y112M-2 | 5.5 | Y132S1-2 | |

| A | 22.7 | 16.5 | 2.2 | Y90L-2 | 3 | Y100L-2 | 4 | Y112M-2 | |

| 65FY-32 | 25 | 32 | 5.5 | Y132S1-2 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |

| A | 22.7 | 26.5 | 4 | Y112M-2 | 4 | Y112M-2 | 5.5 | Y132S1-2 | |

| 65FY-50 | A | 25 | 50 | 11 | Y160M1-2 | 11 | Y160M1-2 | 15 | Y160M2-2 |

| 22.7 | 41 | 7.5 | Y132S2-2 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | ||

| 65FY-80 | 25 | 80 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 22 | Y180M-2 | |

| A | 23.4 | 74.8 | 15 | Y160M2-2 | |||||

| B | 22 | 61.8 | 11 | Y160M1-2 | 18.5 | Y160L-2 | |||

| 80FY-20 | 50 | 20 | 5.5 | Y132S1-2 | 5.5 | Y132S1-2 | 7.5 | Y132S2-2 | |

| A | 45.3 | 16.5 | |||||||

| 80FY-32 | 50 | 32 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |

| A | 45.4 | 26.4 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |||

| 80FY-50 | 50 | 50 | 15 | Y160M2-2 | 15 | Y160M2-2 | 22 | Y180M-2 | |

| A | 45.3 | 41 | 11 | Y160M1-2 | 18.5 | Y160L-2 | |||

| 80FY-80 | A | 50 | 80 | 22 | Y180M-2 | 30 | Y200L1-2 | 45 | Y225M-2 |

| 46.8 | 70.5 | 18.5 | Y160L-2 | 22 | Y180M-2 | 30 | Y200L1-2 | ||

| B | 44 | 62.2 | 15 | Y160M2-2 | |||||

| 100FY-20 | 100 | 20 | 11 | Y160M1-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |

| A | 91.8 | 16.8 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |||

| 100FY-32 | 100 | 32 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 22 | Y180M-2 | |

| A | 91 | 26.5 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |

| 100FY-50 | 100 | 50 | 22 | Y180M-2 | 30 | Y200L1-2 | 37 | Y200L2-2 | |

| A | 91 | 41.5 | 18.5 | Y160L-2 | 22 | Y180M-2 | 30 | Y200L1-2 | |

| 100FY-80 | 100 | 80 | 45 | Y225L2-2 | 45 | Y225M-2 | 75 | Y280S-2 | |

| A | 93.5 | 70 | 37 | Y250L2-2 | 55 | Y250M-2 | |||

| B | 87.8 | 61.7 | 30 | Y250L2-2 | 37 | Y250L2-2 | 45 | Y225M-2 | |

| 100FY-20 | 100 | 20 | 11 | Y160M1-2 | 11 | Y160M1-2 | 15 | Y160M2-2 | |

| A | 91.8 | 16.8 | 7.5 | Y132S2-2 | 11 | Y160M1-2 | |||

| 100FY-32 | 100 | 32 | 15 | Y160M2-2 | 18.5 | Y160L-2 | 22 | Y180M-2 | |

| A | 91 | 26.5 | 11 | Y160M1-2 | 15 | Y160M2-2 | 18.5 | Y160L-2 | |

| 100FY-50 | 100 | 50 | 22 | Y180M-2 | 30 | Y200L1-2 | 37 | Y200L2-2 | |

| A | 91 | 41.5 | 18.5 | Y160L-2 | 22 | Y180M-2 | 30 | Y200L1-2 | |

| 100FY-80 | 100 | 80 | 45 | Y225L2-2 | 45 | Y225M-2 | 75 | Y280S-2 | |

| A | 93.5 | 70 | 37 | Y250L2-2 | 55 | Y250M-2 | |||

| B | 87.8 | 61.7 | 30 | Y250L2-2 | 37 | Y250L2-2 | 45 | Y225M-2 | |

| Model | Impeller type | Speed n=14500r/min | |||||||

| Capacity Q M3/h |

Head H m |

Relative density<1.0 | Relative density<1.35 | Relative density<1.86 | |||||

| Power kw |

Motor model | Power kw |

Motor model | Power kw |

Motor model | ||||

| 25FY-20 | 1.6 | 5 | 0.75 | Y802-4 | 0.75 | Y802-4 | 1.1 | Y90S-4 | |

| A | 1.4 | 4 | |||||||

| 25FY-32 | 1.6 | 8 | 1.1 | Y90S-4 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | |

| A | 1.4 | 6.5 | |||||||

| 25FY-50 | 1.6 | 12.5 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | |

| A | 1.4 | 10 | Y90S-4 | ||||||

| 25FY-80 | 1.6 | 20 | |||||||

| A | 1.5 | 17 | |||||||

| B | 1.4 | 15 | |||||||

| 40FY-20 | 3.2 | 5 | 0.75 | Y802-4 | 0.75 | Y802-4 | 1.1 | Y90S-4 | |

| A | 2.8 | 4 | |||||||

| 40FY-32 | 3.2 | 8 | 1.1 | Y90S-4 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | |

| A | 2.8 | 6.5 | |||||||

| 40FY-50 | 3.2 | 12.5 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | |

| A | 2.8 | 10 | |||||||

| 40FY-80 | 3.2 | 20 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |

| A | 2.9 | 17 | |||||||

| B | 2.8 | 15 | |||||||

| 50FY-20 | 6.3 | 5 | 0.75 | Y802-4 | 0.75 | Y802-4 | 1.1 | Y90S-4 | |

| A | 5.7 | 4.1 | |||||||

| A | 5.7 | 6.6 | |||||||

| 50FY-50 | 6.3 | 12.5 | 1.1 | Y90S-4 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | |

| A | 5.7 | 10.3 | 0.75 | Y802-4 | 1.1 | Y90S-4 | |||

| 50FY-80 | 6.3 | 20 | 1.5 | Y90L-4 | 2.2 | Y80L-4 | 3 | Y100L2-4 | |

| A | 5.7 | 17.5 | 2.2 | Y100L1-4 | |||||

| B | |||||||||

| 65FY-20 | 12.5 | 5 | 0.75 | Y802-4 | 0.75 | Y802-4 | 1.1 | Y90S-4 | |

| A | 11.3 | 4.1 | 0.75 | 0.75 | Y802-4 | ||||

| 65FY-32 | 12.5 | 8 | 0.75 | 1.1 | Y90S-4 | ||||

| A | 11.3 | 6.6 | 0.75 | ||||||

| 65FY-50 | A | 12.5 | 12.5 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 |

| 11.3 | 103 | 1.1 | Y90S-4 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | ||

| 65FY-80 | 12.5 | 20 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | 4 | Y112M-4 | |

| A | 11.7 | 17.5 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |||

| B | |||||||||

| 80FY-20 | 25 | 5 | 0.75 | Y802-4 | 0.75 | Y802-4 | 1.1 | Y90S-4 | |

| A | 22.6 | 4.1 | 0.75 | Y802-4 | |||||

| 80FY-32 | 25 | 8 | 1.5 | Y90L-4 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | |

| A | 22.7 | 6.6 | 1.1 | Y90S-4 | 1.1 | Y90S-4 | 1.5 | Y90L-4 | |

| 80FY-50 | 25 | 12.5 | 2.2 | Y100L1-4 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |

| A | 22.7 | 10.3 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | |||

| 80FY-80 | A | 25 | 20 | 3 | Y100L2-4 | 4 | Y112M-4 | 5.5 | Y132S-4 |

| 23.4 | 17.6 | 3 | Y100L2-4 | 4 | Y112M-4 | 5.5 | Y132S-4 | ||

| B | |||||||||

| 100FY-32 | 50 | 8 | |||||||

| A | 45.5 | 6.6 | 1.5 | Y90L-4 | 2.2 | Y100L1-4 | 3 | Y100L2-4 | |

| 100FY-50 | 50 | 12.5 | 4 | Y112M-4 | 4 | Y112M-4 | 5.5 | Y132S-4 | |

| A | 45.5 | 10.3 | 3 | Y100L2-4 | 3 | Y100L2-4 | 4 | Y112M-4 | |

| 100FY-80 | 50 | 20 | 5.5 | Y132S-4 | 7.5 | Y132M-4 | 11 | Y160M-4 | |

| A | 45.5 | 17.4 | 4 | Y112M-4 | 5.5 | Y132S-4 | 7.5 | Y132M-4 | |

| B | 43 | 15 | |||||||

| 125FY-12.5 | 100 | 12.5 | 5.5 | Y132S-4 | 7.5 | Y132M-4 | 11 | Y160M-4 | |

| A | 91 | 10.3 | 5.5 | Y132S-4 | 7.5 | Y132M-4 | |||

| 125FY-20 | 100 | 20 | 11 | Y160M-4 | |||||

| A | 91 | 16.5 | 7.5 | Y132M-4 | 11 | Y160M-4 | 15 | Y160L-4 | |

| 125FY-32 | 100 | 32 | 18.5 | Y180M-4 | 22 | Y180L-4 | 30 | Y200L-4 | |

| A | 91 | 25.5 | 15 | Y160L-4 | 18.5 | Y180M-4 | 30 | Y200L-4 | |

| 125FY-50 | 100 | 50 | 37 | Y225S-4 | 55 | Y250M-4 | |||

| A | 91 | 41 | 30 | Y200L-4 | 30 | Y200L-4 | 45 | Y225M-4 | |

| 150FY-20 | 200 | 20 | 18.5 | Y180M-4 | 22 | Y180L-4 | 30 | Y200L-4 | |

| A | 182 | 16.5 | 15 | Y160L-4 | 18.5 | Y180M-4 | 30 | Y200L-4 | |