Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Forged Steel, Cast Steel.

Size: 1/2"~48", DN15~DN1400.

Pressure: 150LB~2500LB, PN10~PN420.

Type: Trunnion Mounted, Floating, Top Entry, 2PCS, 3PCS, Wafer, Flanged, Steam Jacketed, Cryogenic, Low Tempreature, Moterized, Pneumatic, Metal Seated, PTFE Seated.

Ball Valve is a kind of quarter-turn valve which utilizes a hollow, perforated and pivoting ball (known as a "ball") to manage flow through it. It's open once the ball's hole is using the flow and closed when the ball valve’s pivoted 90-levels through the valve handle. The handle lies flat in alignment using the flow when open, and it is verticle with respect into it when closed, creating easy visual confirmation from the valve's status.

Shinjo ball valves are durable in most cases try to achieve perfect shutoff despite many years of disuse. They're therefore a great option for shutoff applications (and therefore are frequently chosen over globe valves and gate valves for this function). They don't provide the fine control which may be necessary in throttling applications but they are sometimes used for this function.

Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron Forged Steel, Cast Steel.

Size: 1/2"~28", DN15~DN800.

Pressure: 150LB~2500LB, PN10~PN420.

Type: Swing, Dual Plate, Wafer, Pressure Seal, Y Type, Flanged, Cryogenic, Low Tempreature, Lift, Ball Type, Tilting Disc, Rubber Flapper, Lined, Non Slam, Silent, Vertical, Multifunctional, Sanitary.

A check valve, clack valve, non-return valve a treadmill-way valve is really a mechanical device, a valve, which normally enables fluid (liquid or gas) to circulate through it in just one direction. Check valves are a couple of-port valves, meaning they've two openings in your body, one for fluid to go in and yet another for fluid to depart. There are numerous kinds of check valves utilized in a multitude of applications. Check valves are frequently a part of common household products. Although these come in an array of sizes and charges, many check valves are extremely small, simple, and/or cheap. Check valves work instantly and many aren't controlled with a person or any exterior control accordingly, most have no valve handle or stem. The bodies (exterior shells) on most check valves are constructed with plastic or metal.

An essential concept in check valves may be the cracking pressure the minimum upstream pressure where the valve will operate. Often the check valve is made for and may therefore be specified for any specific cracking pressure.

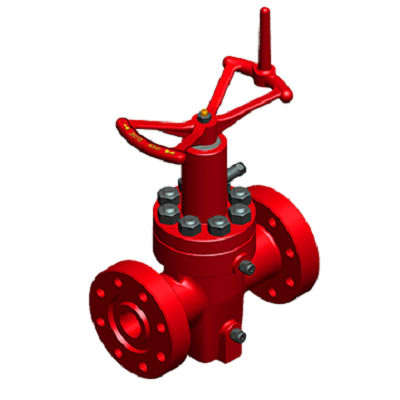

Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Forged Steel, Cast Steel.

Size: 1/2"~48", DN15~DN1400.

Pressure: 150LB~2500LB, PN10~PN420.

Type: Knife, Slab, Threaded, Bellow Sealed, Pressure Dsealed, Resilient Seated, Flanged, Steam Jacketed, Cryogenic, Low Tempreature, Moterized, Pneumatic.

Gate valves are utilized whenever a straight-line flow of fluid and minimum restriction is preferred. Gate valves are extremely named since the part that either stops or enables flow with the valve functions somewhat such as the opening or closing of the gate and it is known as, appropriately, the gate. The gate is generally wedge formed. Once the valve is available, the gate is fully attracted up in to the valve, departing a dent for flow with the valve exactly the same size because the pipe where the valve is installed. Therefore, there's little pressure drop or flow restriction with the valve. Gate valves aren't appropriate for throttling purposes because the charge of flow could be difficult because of valve design because the flow of fluid slapping against a partly open gate may cause extensive harm to the valve. Except as particularly approved, gate valves shouldn't be employed for throttling.

Gate Valve Gate valves are called either RISING STEM or NONRISING STEM valves. Around the nonrising-stem gate valve, the stem is threaded around the lower finish in to the gate. Because the handwheel around the stem is rotated, the gate travels up or lower the stem around the threads, as the stem remains vertically stationary. This kind of valve more often than not includes a pointer-type indicator threaded to the upper finish from the stem to point valve position.

The increasing-stem gate valve has got the stem connected to the gate the gate and stem rise minimizing together because the valve is operated.

Gate valves utilized in steam systems have flexible gates. The reason behind utilizing a flexible gate would be to prevent binding from the gate inside the valve once the valve is incorporated in the closed position. When steam line is heated, they'll expand, causing some distortion of valve physiques. If your solid gate fits snugly between your seat of the valve inside a cold steam system, once the product is heated and pipes elongate, the seats will compress from the gate, wedging the gate together and clamping the valve shut. This issue is overcome by utilization of an adaptable gate (two circular plates mounted on one another having a flexible hub in the centre). This design enables the gate to flex because the valve seat compresses it, therefore stopping clamping.

We are able to supply an array of Gate Valves covering Universal Gate Valves of Cast Iron Gate Valve, Ductile Iron Gate Valve, Cast Steel Gate Valve and Forged Steel Gate Valve, Cryogenic Gate Valves, Bellow Sealed Gate Valves and Sliding Gate Valves etc.

All the Gate Valves are made, manufactured and tested to API, ASTM, ANSI, JIS, Noise and BS Standards.

Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Forged Steel, Cast Steel.

Size: 1/2" ~48", DN15~DN1400.

Pressure: 150LB~2500LB, PN10~PN420.

Type: Bellow Sealed, Y Type, Angle Type, Flanged, Steam Jacketed, Cryogenic, Low Tempreature, Moterized, Pneumatic, Power Station.

A globe valve is a kind of valve employed for controlling flow inside a pipeline, composed of the movable disk-type element along with a stationary ring seat inside a generally spherical body.Globe valves are named for his or her spherical physique using the two halves from the body being separated by an interior baffle. It has a dent that forms a seat onto that your movable plug could be screwed directly into close (or shut) the valve.

Globe Valve The plug can also be known as a disc ordisk. In globe valves, the plug is linked to a stem that is run by screw action utilizing a handwheel in manual valves. Typically, automated globe valves use smooth stems instead of threaded and therefore are opened up and closed by an actuator set up.Although globe valves previously had the spherical physiques which gave them their name, many modern globe valves don't have a spherical shape. However, the word globe valve continues to be frequently employed for valves which have this kind of internal mechanism. In plumbing, valves with your a mechanism will also be frequently known as stop valves given that they not have the global appearance, however the term stop valve may make reference to valves which are utilized to stop flow even whether they have other mechanisms or designs.Globe valves can be used for applications requiring throttling and frequent operation.

For instance, globe valves or valves having a similar mechanism can be utilized as sampling valves, that are normally shut except when liquid samples are now being taken. Because the baffle restricts flow, they are not suggested where full, unobstructed flow is needed.

Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Cast Steel.

Size: 1/2" ~24", DN15~DN600.

Pressure: 150LB~1500LB, PN10~PN320.

Type: Threaded, Lubricated, Sleeved, Lined, 3 Way, Lift, Double Block & Bleed, Full Port, Eccentric, Metal Seated, PTFE Seated, Pressure Balanced, Flanged, Steam Jacketed, Cryogenic, Low Tempreature, Moterized, Pneumatic.

Plug valves are valves with round or conically tapered "plugs" which may be rotated within the valve body to manage flow with the valve. The plugs in plug valves have a number of hollow passageways going sideways with the plug, to ensure that fluid can flow with the plug once the valve is open.

Plug valves are pretty straight forward and frequently economical.Once the plug is conically tapered, the stem/handle is usually connected to the bigger diameter finish from the plug. Plug valves tend not to have bonnets but frequently possess the finish from the plug using the handle uncovered or mostly uncovered towards the outdoors. In such instances, there's not often a stem. The stem and take care of frequently come successfully, frequently an easy, roughly L-formed handle connected to the finish from the plug. Another finish from the plug is frequently uncovered towards the outdoors from the valve too, however with a mechanism that maintains the plug in your body.

The easiest and many common general kind of plug valve is really a 2-port valve with two positions: available to allow flow, and shut (closed) to prevent flow. Ports are openings within the valve body by which fluid can enter or leave. The plug in this sort of valve has one passageway dealing with it. The ports are usually at opposite ends from the body therefore, the plug is rotated a 4th of the full use vary from available to shut positions. This will make this sort of plug valve one fourth-turn valve. There's frequently a mechanism restricting motion from the handle to some quarter turn, although not in glass stopcocks.Slightly conically tapered metal (frequently brass) plug valves are frequently utilized as simple shut-off valves in household gas lines.It's also feasible for a plug valve to possess greater than two ports. Inside a 3-way plug valve, flow in one port might be forwarded to either the 2nd or third port. A 3-way plug valve may be made to shift flow between ports 1 and a pair of, 2 and three, or one and three, and perhaps even connect the 3 ports together.

The flow-directing options in multi-port plug valves are the same options in corresponding multi-port ball valves or corresponding multi-port valves having a rotor. Yet another possibility in plug valves may be the get one port somewhere from the plug valve and 2 ports on the other hand, with two diagonal and parallel fluid pathways within the plug. Within this situation the plug could be rotated 180° for connecting the main harbour around the one for reds either to of these two ports on the other hand.

Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Cast Steel.

Size: 1-1/2" ~80", DN40~DN2000.

Pressure: 150LB~300LB, PN10~PN40.

Type: Wafer, Flanged, Double Offset, Triple Offset, Moterized, Pneumatic, Rubber Lined, PTFE Lined.

Butterfly valve is a valve that you can use for isolating or controlling flow. The closing mechanism takes the type of a disk. Operation is comparable to those of a ball valve, which enables for convenient turn off. Butterfly valves are usually favored since they're reduced cost with other valve designs in addition to being light, meaning less support is needed. The disc lies in the heart of the pipe, passing with the disc is a fishing rod linked to an actuator around the outdoors from the valve. Rotating the actuator turns the disc either parallel or verticle with respect towards the flow. Unlike a ball valve, the disc is definitely present inside the flow, therefore a pressure drop is definitely caused within the flow, no matter valve position. A butterfly valve comes from a group of valves known as quarter-turn valves.The "butterfly" is a metal disc installed on a fishing rod. Once the valve is closed, the disc is switched in order that it completely blocks from the passageway. Once the valve is fully open, the disc is rotated a quarter turn in order that it enables a nearly unrestricted passage from the fluid. The valve can also be opened up incrementally to throttle flow. There are various types of butterfly valves, each adapted for various pressures and various usage. The resilient butterfly valve, which utilizes the versatility of rubber, has got the cheapest pressure rating. Our prime performance butterfly valve, utilized in slightly greater-pressure systems, features a slight offset in the manner the disc lies, which boosts the valve's sealing ability and reduces its inclination to put on. The valve ideal for top-pressure systems may be the triple offset butterfly valve, which utilizes a metal seat, clarification needed and it is therefore in a position to withstand a greater quantity of pressure.

Material: Stainless Steel, Carbon Steel, Brass, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Cast Steel.

Size: 1/2" ~18", DN15~DN450.

Pressure: 150LB~2500LB, PN10~PN420.

Type: Full Lift, Balanced Bellow, Bellow Seal, Flanged, Steam Jacketed, Low Tempreature, High Tempreature, Power Station.

Safety valve is a valve mechanism which instantly releases a substance from a boiler, pressure vessel, or any other system, once the pressure or temperature exceeds preset limits.It is among a group of pressure safety valves (PSV) or pressure relief valves (PRV), that also includes relief valves, safety relief valves, pilot-operated relief valves, low pressure safety valves, and vacuum pressure safety valves.Safety valves were first utilized on steam boilers throughout the Industrial Revolution. Early boilers operating without one were vulnerable to accidental explosion.Vacuum safety valves (or combined pressure/vacuum safety valves) are utilized to prevent a tank from collapsing even though it is being emptied, or when cold rinse water can be used after hot CIP (clean-in-place) or SIP (sterilization-in-place) procedures.

When sizing a vacuum safety valve, the calculation technique is not defined in almost any norm, especially in the hot CIP / cold water scenario, however, many manufacturers allow us sizing simulations.

Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Ductile Iron, Cast Iron, Cast Steel.

Size: 1"~32", DN25~DN800.

Pressure: 150LB, PN10~PN16.

Type: Float, Angle Float, Pressure Reducing, Non Surge, Solenoid, Pressure Relief & Sustaining, Pump, Altitude, Water Level, Flanged, Moterized.

Hydraulic is designed mostly mounted on the water pump's outlet pipeline of the high buildings and other water supply systems to prevent of the medium's back-flow and the water hammer and water shock.

Good effect of water hammer removal. Integrating the technical principles of water hammer removal by means of slow open, quick close and slow close, so as to prevent of the water hammers at both pump start and stop.

Easy operation. The valve will open or close automatically as per the operation procedures of the pump, once operates the On-Off button of the pump's motor.

Good effect of energy saving. The valve body is designed as full-path straight-flow type, resulting in small pressure loss, big flow, small volume and light weight.

Material: Stainless Steel, Carbon Steel, Alloy Steel, Titanium, 904l, Cast Steel.

Size: 1/2"~18", DN15~DN400.

Pressure: 150LB-2500LB, PN10~PN420.

Type: Globe Type, Double Seat, Single Seat, V Port, Ball Type, V Ball, Cage, Angle Type, 3 Way, Self Opreated, Pressure, Tempreature, High Tempreature, Power Station, Cv3000, Flanged, Cryogenic, Low Tempreature, Moterized, Pneumatic.

Control valves are valves accustomed to control conditions for example flow, pressure, temperature, and liquid level by fully or partly opening or closing as a result of signals caused by controllers that compare a "setpoint" to a "process variable" whose value is supplied by sensors that monitor alterations in such conditions.

Control valves are valves accustomed to control conditions for example flow, pressure, temperature, and liquid level by fully or partly opening or closing as a result of signals caused by controllers that compare a "setpoint" to a "process variable" whose value is supplied by sensors that monitor alterations in such conditions.The outlet or closing of control valves is generally done instantly by electrical, hydraulic or pneumatic actuators. Positioners are utilized to control the outlet or closing from the actuator according to electric, or pneumatic signals. These control signals, typically according to 3-15psi (.2-1.0bar), more prevalent now are 4-20mA signals for industry, -10V for Heating and cooling systems, and the development of "Smart" systems, HART, Fieldbus Foundation, and Profibus to be the more prevalent protocols.

A control valve includes three primary parts by which each part appear in several types and fashions : Valve's actuator, Valve's positioner, Valve's body.

Nowadays with the introduction of the modernized industrial automatic controlling system progressing, the necessity to control valve elevated. Shinjo because of so many years development and research, developed ZH series direct travel control valve and ZR series position travel control valve. Compact structure, advanced operation actuator system. Relevant medium are Liquid, Gas and Steam. Shinjo control valve rich in durability and stability, simple for type selecting. Structure simplified, reduced the spares in great quantity, more convenien for valve maintenance and reduced the constant maintenance cost.

Characteristics:

Easy calculation and option

Convenient maintenance

Enhanced spares for compatibility to various size.

Low application cost.

High durability and compactability

Can offer integrated control valve with actuator

Valve size vary from DN25 to DN500 (1'' to 20'')

Pressure grade vary from PN10 to PN420(ANSI Class150 to 1500)

Wide selection of type option

Broadly utilized in:

Hemical industry

Power plant

Petrochemical industry

Paper making industry

Steel plant

Shipping industry

Ecological protection industry

Fire extinguish system

Material: Stainless Steel, Carbon Steel, Alloy Steel, Titanium, 904l, Cast Steel.

Size: 1/2"~18", DN15~DN400.

Pressure: 150LB-2500LB, PN10~PN420.

Type: Globe Type, Double Seat, Single Seat, V Port, Ball Type, V Ball, Cage, Angle Type, 3 Way, Self Opreated, Pressure, Tempreature, High Tempreature, Power Station, Cv3000, Flanged, Cryogenic, Low Tempreature, Moterized, Pneumatic.

Control valves are valves accustomed to control conditions for example flow, pressure, temperature, and liquid level by fully or partly opening or closing as a result of signals caused by controllers that compare a "setpoint" to a "process variable" whose value is supplied by sensors that monitor alterations in such conditions.The outlet or closing of control valves is generally done instantly by electrical, hydraulic or pneumatic actuators. Positioners are utilized to control the outlet or closing from the actuator according to electric, or pneumatic signals. These control signals, typically according to 3-15psi (.2-1.0bar), more prevalent now are 4-20mA signals for industry, -10V for Heating and cooling systems, and the development of "Smart" systems, HART, Fieldbus Foundation, and Profibus to be the more prevalent protocols.

A pneumatic control valve includes three primary parts by which each part appear in several types and fashions : Valve's actuator, Valve's positioner, Valve's body.

Material: Stainless Steel, Carbon Steel, Brass, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Cast Steel.

Size: 1/2" ~18", DN15~DN800.

Pressure: 150LB~1500LB, PN10~PN420.

Type: Piston, Diaphragm, Self Opreated, Electric, Flanged, Cryogenic, Moterized, Pneumatic.

Pressure Reducing Valve is a valve that instantly reduces the flow of a liquid or gas at a certain pressure. Regulators are utilized to allow high-pressure fluid supply lines or tanks to become reduced to safe and/or functional pressures for a number of applications. Gas pressure regulators are utilized to regulate the gas pressure and aren't suitable for calculating flow rates. Flowmeters, Rotometers or Mass Flow Controllers should be employed to precisely regulate gas flow rates.

Material: Stainless Steel, Carbon Steel, Alloy Steel, Titanium, 904l, Forged Steel.

Size: 1/2"~2", DN15~DN50.

Pressure: 150LB~2500LB, PN10~PN420.

Type: Angle Type, Union Bonnet.

Accurate flow measurement is of primary importance in achieving an efficient process system. Shinjo offers a complete line of needle, gauge and instrument manifold valves designed to provide accurate, safe and dependable flow measurement. Manufactured for Shinjo, the design of these valves reflects extensive engineering and manufacturing experience, resulting in attainment of the highest standards for valve quality and reliability.

Material: Stainless Steel, Carbon Steel, Brass, Bronze, Alloy Steel, Titanium, 904l, Ductile Iron, Cast Iron, Cast Steel.

Size: 1/2"~24", DN15~DN800.

Pressure: 150LB~1500LB, PN10~PN320.

Cast Steel Valves are available for the multiple valve types, including gate valves, globe valves, and swing check valves.

Shinjo's comprehensive line of cast steel gate globe and check valves features leading edge design, engineering and manufacturing technology. Our valves meet the most stringent national and international standards for fugitive emissions.

Our gate globe and check valves are widely used in process industries including: Oil, Chemical, Petrochemical, Refining, Pulp & Paper, Pharmaceutical and Food Processing.

Material: Stainless Steel, Carbon Steel, Alloy Steel, Titanium, 904l, Forged Steel.

Size: 1/2"~48", DN15~DN1400.

Pressure: 150LB~2500LB, PN10~PN420.

Shinjo's forged steel gate, globe, check valves have been proven in critical service applications all over the world. Today Shinjo’s comprehensive range of gate, globe, check, angle, and bellows seal valves remain the leading choice for high performance in virtually any industrial application.

Material: Stainless Steel, Carbon Steel, Brass, Ductile Iron, Cast Iron, Cast Steel.

Size: 1/2"~16", DN15~DN400.

Pressure: 150LB, PN10~PN16.

Type: Circuit, Calibrated, Self BaLBacing, Threaded, Flanged.

In the fundamental concepts of regulation point of view balancing valve is really an instructions for that regulation valves. In balancing valve upstream and downstream ends from the tube with a hole, accustomed to appraise the fluid through valves pressure reduction. Use, detected valves pressure reduction and browse the levels, can be viewed as through the flow valves. Its role to controlling valves and flow-combination hole equal to the slip route to the flow distribution needs. Once the total cycle pump gear shift operation, the flow from the slip road ratio unchanged.

Balancing valve dynamics operating concepts: through alterations in the flow Disc balancing valve the region round the valves to sit in the modification, thus achieving the objective of flow control. Is a dynamic balancing valve local potential to deal with change spending components. When balancing valve and differential pressures are smaller sized compared to tiniest start differential pressures weren't compressed spring-loaded, the biggest circulation area. When balancing valve and differential pressures past the scope of labor is totally compressed spring-loaded valves guts, guts flow only from valves on sides from the square shed, when valves guts into a fixed regulator, the flow and differential pressures compared using the increase and differential pressures increase. balancing valve possess some great pressure inside the air-conditioning equipment to limit the utmost flow, automatic constant flow characteristics, within the large-type, complex, ac load isn't constant heating works, a simplification from the system into debugging, and shorten the debugging time.

Material: Stainless Steel, Carbon Steel, Alloy Steel, Cast Iron, Cast Steel.

Size: 1/2" ~16", DN15~DN400.

Pressure: 150LB, PN10~PN16.

Type: Weir Type, Straight Through, Flanged, Moterized, Pneumatic, 3 Way, Y Type, PTFE Lind, Rubber Lined.

Diaphragm valves are based on pinch valves, but make use of an elastomeric diaphragm, rather of the elastomeric liner within the valve body, to split up the flow stream in the closure element. Rather of pinching the liner closed to supply shut-off, the diaphragm is pressed into connection with the foot of the valve body to supply shut-off. Diaphragm valves are fantastic for manipulating the flow of fluids that contains suspended solids and provide the versatility to be set up in any position. These kinds of valves have discovered prevalent use within the pharmaceutical, food processing, and water treatment industries. Manual diaphragm valves are perfect for flow control by providing a variable and precise opening for controlling pressure drop with the valve. Actuated varieties can provide features as adjustable opening, positioners for precise flow control, and electric relay of valve position.The benefits supplied by diaphragm valves are lots of. They're very clean, and may form a nearly leak-proof seal for tight shut-off. The diaphragm design offers easy repair and maintenance as possible replaced without disturbing the piping line. However, they're limited they're restricted to moderate temperature (-60 to 450F) and pressure service (roughly 300 psi) through the mechanical qualities on most common diaphragm materials. They can't be utilized in multi-turn operations. Diaphragm valves can be found in two fundamental forms: weir type and straight through types. The weir design is the best for general use applications or tough corrosive and abrasive services. The straight through type may be used in situations in which the flow direction changes inside the system. They're good for use with sludge, slurries along with other viscous fluids. Each style provide a streamlined path for fluid flow that yields minimal pressure drop over the valve.

The flow transfer and control category covers a wide spectrum of merchandise made to facilitate, control, maintain, meter, or browse the flow of fabric through hoses, pipes or tubing. The fabric under consideration could be liquid, gaseous, or semi-solid (colloids and slurries). The next families fall in this particular category: valves, valve actuators and positioners, dispensing valves, pumps, flow sensing, level sensing, density and particular gravity sensing, viscosity sensing, and miscellaneous related products.

We provide a number of Diaphragm Valves covering Cast Iron Diaphragm Valve, Ductile Iron Diaphragm Valve, Cast Steel and Stainless Steel Diaphragm Valve: Straight Through Type Diaphragm Valve, Weir Type Diaphragm Valve, Flanged Diaphragm Valve and Threaded Ends Diaphragm Valve etc. All the Diaphragm Valves are made, manufactured and tested to API, ASTM, ANSI, JIS, Noise and BS Standards.

Material: Stainless Steel, Carbon Steel, Alloy Steel, Cast Steel.

Size: 12"~48", DN300~DN1600.

Pressure: 150LB, PN10~PN420.

Blind valves has been utilized to pipelines in a variety of industries wherever either positive shutoff is most concerned or full flow ought to be achieved without pressure drop.

The typical practice for line blinding by utilizing typical materials for example spectacle blinds, spool piece, blind flange valves etc. with gaskets placed between flanges has however been work intensive & time intensive and therefore led to making expense factors including time needed for that blinding/blanking process, lack of productivity brought on by lengthy blinding time as well as the operators from the production line happen to be unavoidably uncovered towards the potential hazard of explosion, fire, pollution as well as in halation.

Material: Stainless Steel, Carbon Steel, Alloy Steel, Cast Iron, Cast Steel.

Size: 1/2"~16", DN15~DN400.

Pressure: 150LB, PN10~PN16.

Type: PTFE Lind, Rubber Lined, PFA Lined, FEP Lined.

Lined valves and accessories use fluorocarbons such as PFA, PVDF, PTFE, PFA-AS (antistatic), and UHMWPE upon customer request.

The melt process allows the liner to be locked into dovetails, locking grooves, and locking holes in the casting. Consequently, the potential for liner collapse and blow out is minimized.

Additionally, PFA and FEP liners are inherently less porous than PTFE.

.jpg)

.jpg)

.jpg)

.jpg)

-electric-3-way-control-valve(1).jpg)

.jpg)

-pneumatic-diaphragm-3-way-control-valve.jpg)