Key Specifications / Features

Model No.: SJ-ECV-01 Hits: 106

Detail Information

Parts & Material:

1. Body: A105.

2. Bonnet: A105.

3. Stem: SS304/20Cr13.

4. Disc: SS304/20Cr13.

5. Seat: SS304/20Cr13.

6. Packing: Flexible Graphite.

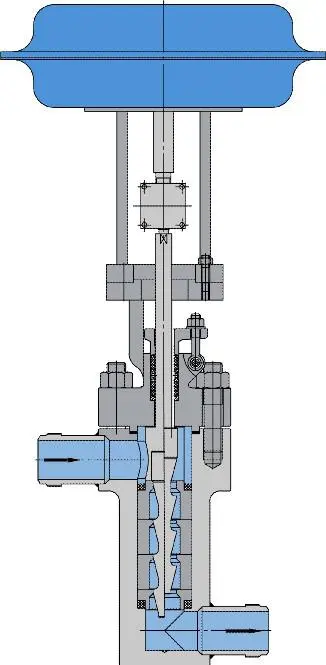

1. The valve is mainly made of body, seat, sleeve, support, stem and bonnet and so on, apply with the electric actuator and pneumatic actuator

2. As for this series control valves, the seat and disc are designed out with many different structure types, it can meet many different throttle way and its flow characteristic are two types of linear and equal-percentage.

3. The valve is Z shape structure, multi-level throttle, and high adjusting accuracy, can adjust the cooling water for many different differential pressure and flow types condition.

4. Every level of throttle part was made of reasonable linear type, which can prevent the cavitation and noise, and keep the adjusting steadily.

5. The sealing ring between the seat applies with the flexible graphite with good compressibility and sealing performance, when the valve is closed, it hardly has the leakage.

Installation:

1. The valve must be installed on the pipeline vertically, connected with flange.

2. The flow direction on the valve body shall same to the installation direction.

3. In installation, the opening and closing position of the electric actuator shall same to the valve.

4. When clean the pipeline, some necessary measures shall be took in order to prevent the valve from sticking because of something left between the disc and seat, which may reduce the working life.

Confirmation Before Order:

1.Type (Including the actuator type, connect type, and material of the body and so on).

2. Nominal Pressure PN (MPa).

3. Nominal Diameter DN (mm).

4. Working Pressure (MPa).

5. Pressure differential of Water: Inlet pressure (MPa) and outlet pressure (MPa).

6. Water Temperature (℃).

7. Cv value or the maximal flow rate (t/h).

8. Other technical requirement.

If the electric actuator is applied, the controlling signal shall be noted (0~10 or 4~20mA), if the pneumatic actuator is applied, bellow information shall be noted:

1. If hand wheel is needed;

2. Air filter pressure reducer;

3. Positioner, if it is the electro pneumatic valve positioner, please note the electric signal (0~10 or 4~20mA);

4. Air supply pressure;

5. Air-closing or air-opening.