Key Specifications / Features

Model No.: SJ-SCP-01 Hits: 116

Detail Information

A. Split Case Pumps Application:

Split Case Pumps

Split case pumps is suitable for transferring various liquids, such as clean liquids or neutral liquids with particles or weak-erosion liquids with particles. The product is applicable to water supply plant, agricultural irrigation, power station, drainage in pumps station, water supply system in the industrial field, air-conditioning system, fire-fighting system, boat and ship industry as well as oil refining industry as an general equipment.

B. Split Case Pumps Scope of Performance:

| Diameter of pumps inlet | DN | 100-1400mm |

| Capacity | Q | 0~18000m3/h |

| Head | H | 0~ 135m |

| Working Pressure | P | 0~ 2.5MPa |

| Working Temp. | T | 0~135℃ |

C. Split Case Pumps Structure lnstruction:

S series pumps is the single grade, double absorption, horizontal, axial split, volute, centrifugal pumps. The inlet and outlet of the pumps are both located under the shaft centerline and distributed horizontally.

Components & spare parts lower casing, upper casing, impeller, shaft, wearing ring etc.

There are some pipe threaded holes designed for installing vacuum gauge and pressure meter on the pump's flange, and on the bottom of the flange, pipe threaded holes are made for draining of water. The pumps flange is manufactured according to GB standard, is also can be made by adopting ISO, DIN, BS or ANSI standards. The impeller checked by statically equilibrium is fixed on the shaft by shaft sleeves and shaft sleeve nuts. The axial position can be adjusted by shaft sleeve nuts. For the balance of the axial thrust of the impeller, it can use the symmetrical arrangement of the vanes of the impeller to meet the balance requirement.

The pumps shaft is supported by two sets of bearing which are installed on the two ends of the lower casing and are lubricated by oil grease.

The wearing ring is equipped with the lower casing, and they are convenient to dismantle and replacement. The pumps are directly driven by the motor through flexible or metal reiterative chip of flexibility coupler. The driver also can be substituted by the diesel engine and steamer engine.

The pumps can be sealed by packing or by mechanical seal The cooled washing water can flow into the shaft sealing house through the concave groove on the split surface of the upper casing, or through the outer cooled water pipe equipped.

When inspecting series S pumps, it is not required to disassemble the inlet and outlet pipe and motor, it is easy for maintenance.

The structural size of the pumps can be changed as the customers' requirement.

D. Split Case Pumps Rotary Direction:

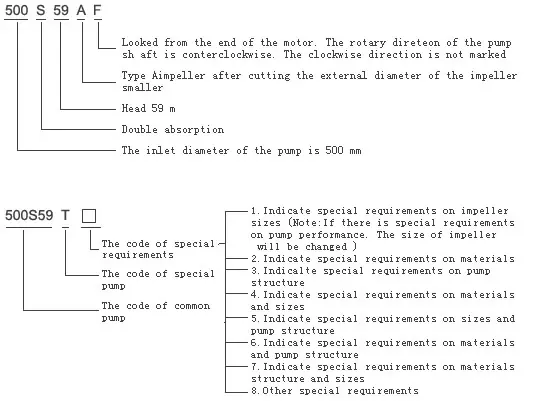

Looked from the end of the motor, the rotary direction of the pump's shaft is clockwise (the pump's inlet is on the right). It also can be changed to the counterclockwise direction, the symbol of the pumps is an additional character "F" added at the end of pumps model (please see the following model instruction)

E. Split Case Pumps Material:

If there are not any special requirements from customers, the material of the main components of the pumps is as the following: Lower casing, upper casing, impeller, wearing ring and shaft sleeves are all made of grey cast iron.

The pumps shaft is made of 45# carbon steel. It also can be made of 410 S.S., 40Cr, etc.

Other liquid-flowing parts and components can be made of the materials: such as ductile cast iron, cast steel bronze and stainless steel.

F. Split Case Pumps Model Instruction:

Split Case Pumps Model Instruction