Key Specifications / Features

Model No.: SJ-PV-04 Hits: 314

Detail Information

Overview

Non-Lubricated, Sleeved Plug Valve is relevant towards the cutting and connection of pipeline's medium that turned on in a variety of industries for example oil, chemical industry, pharmacy, chemical fertilizer, power industry etc.

Sleeved Plug Valve under nominal pressure of sophistication 150-900 Lbs, and works in the temperature of -29 ~ 180C.

a. The merchandise has reasonable structure, reliable sealing, excellent performance and delightful appearance.

b. Sleeved Plug Valve's sealing is recognized through the sealing face round the sleeve. It's unique all over metal edge for defense and fixing from the sleeve.

c. There's no cavity within the Plug valves for that accumulation of medium.

d. Metal edge offers the purpose of self-cleaning once the plug is rotated. It's relevant towards the operation condition that's glutinous sand likely to smudge.

e. Sleeved Plug Valve's double-direction flow makes installation and employ easier.

f. The types of materials from the parts and dimensions of flanges could be configured reasonably based on the actual operation condition the client needed, in order to satisfy the various needs of engineering.

Specifications

| Driving | Handwheel, Worm Gear, Pneumatic, Electric Actuator |

| Design Standard | API 599, API 6D |

| Face to Face | ASME B16.10 |

| Flange End | ASME B16.5 |

| Test & Inspection | API 598, API 6D |

Performances

| PN (Lbs) | Shell test (MPa) | Sealing test (MPa) | Suitable temperature | Suitable medium |

| 150 | 3.0 | 2.2 | ≤ 180°C | Water oil &gas |

| 300 | 7.5 | 5.5 | ||

| 600 | 15.0 | 11.0 | ||

| 900 | 22.5 | 16.5 |

Materials

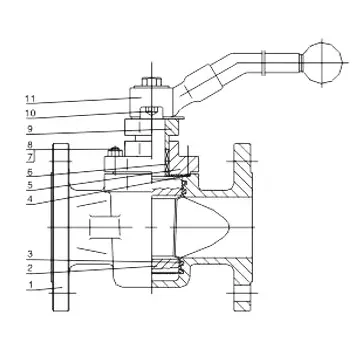

| NO | Part name | Material |

| 1 | Body | ASTM A216-WCB ASTM A351-CF8, CF8M, CF3, CF3M |

| 2 | Sleeve | PTFE |

| 3 | Plug | ASTM A217-WC1, WC6, WC9, C5 ASTM A351-CF8, CF8M, CF3, CF3M |

| 4 | Gasket | PTFE |

| 5 | Adjusting gasket | ASTM A182-F304, F316, F321, F304L, F316, ASTM A182-Gr.F6a ASTM A182-F22 |

| 6 | Cover | ASTM A216-WCB, ASTM A351-CF8, CF8M, CF3, CF3M |

| 7 | Bolt | ASTM A194-2H, A194-8, A194-8M |

| 8 | Nut | ASTM A194-2H, A194-8, A194-8M |

| 9 | Adjusting Gland | ASTM A216-WCB, ASTM A351-CF8, CF8M, CF3, CF3M |

| 10 | Nut | ASTM A193-B7,A193-B8,A193-B8M |

| 11 | Wrench | ASTM A216-WCB |

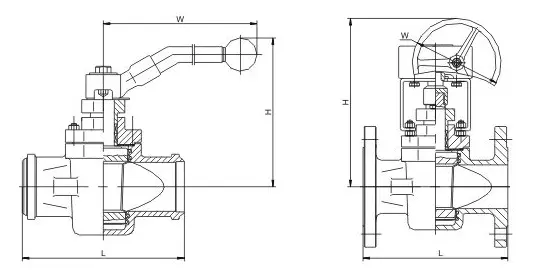

Dimensions and Weights

| Pressure | 150 Lbs | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RF | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 245 | 267 | 292 | 330 | 356 | 381 | |

| L-BW | 152 | 178 | 203 | 216 | 229 | 267 | 305 | 330 | 356 | 381 | 394 | 457 | 533 | 610 | 686 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 520 | 580 | 260 | 680 | 760 | |

| W | 175 | 175 | 175 | 220 | 280 | 305 | 350 | 405 | 300 | 300 | 320 | 320 | 350 | 380 | 450 | |

| Weight(Kg) | 8.5 | 9.5 | 10.0 | 12 | 14 | 22 | 22 | 26 | 40 | 60 | 70 | 130 | 219 | 381 | 570 | |

| Pressure | 300 Lbs | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RF | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 245 | 267 | 292 | 330 | 356 | 381 | |

| L-BW | 152 | 178 | 203 | 216 | 229 | 267 | 305 | 330 | 356 | 381 | 394 | 457 | 533 | 610 | 686 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 520 | 580 | 260 | 680 | 760 | |

| W | 175 | 175 | 175 | 220 | 280 | 305 | 350 | 405 | 300 | 300 | 320 | 320 | 350 | 380 | 450 | |

| Weight(Kg) | 8.5 | 9.5 | 10.0 | 12 | 14 | 22 | 22 | 26 | 40 | 60 | 70 | 130 | 219 | 381 | 570 | |

| Pressure | 600 Lbs | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RF, BW | 165 | 190 | 216 | 229 | 214 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 520 | 580 | 260 | 680 | 760 | |

| W | 175 | 175 | 175 | 220 | 280 | 305 | 350 | 405 | 300 | 300 | 320 | 320 | 350 | 380 | 450 | |

| Weight(Kg) | 11 | 13 | 17 | 20 | 23 | 27 | 31 | 36 | 72 | 98 | 141 | 245 | 330 | 515 | 710 | |

| Pressure | 900 Lbs | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L-RF, BW | 229 | 229 | 254 | 279 | 305 | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | |

| H | 110 | 115 | 115 | 135 | 140 | 150 | 165 | 180 | 380 | 460 | 520 | 580 | 260 | 680 | 760 | |

| W | 175 | 175 | 175 | 220 | 280 | 305 | 350 | 405 | 300 | 300 | 320 | 320 | 350 | 380 | 450 | |

| Weight(Kg) | 13 | 16 | 21 | 24 | 28 | 32 | 40 | 47 | 91 | 117 | 165 | 285 | 420 | 610 | 860 | |

Fig.1: Pneumatic Actuated Sleeved Plug Valve

Fig.1: Low Temperature Sleeved Plug Valve

Fig.1: PTFE Lined Sleeved Plug Valve

.jpg?q=80&fm=webp&s=5b50f33ffb4fe8c0c5a52f6fdd77333a)