Working principle of steam pressure reducing valve (PRV) ?

Steam sometimes causes condensation, and condensed water loses less energy at low pressure. The steam after decompression reduces the pressure of condensate and avoids the flash steam when it is discharged. The temperature of saturated steam is related to pressure. In the sterilization process and surface temperature control of paper dryer, pressure relief valves are needed to control the pressure and further control the temperature. Some systems are with high-pressure condensate water to produce low-pressure flash steam to achieve the purpose of energy-saving when the flash steam is insufficient or steam pressure exceeds the set value where needs a pressure reducing valve.

The types of steam pressure reducing valve

There are many types of steam pressure reducing valve, they can be divided into direct-acting pressure reducing valve, piston pressure reducing valve, pilot-operated pressure reducing valve and bellows pressure reducing valve according to their structure.

Direct-acting pressure reducing valve has a flat diaphragm or bellow and does not need to install external sensing lines downstream because it is independent. It is one of the smallest and most economical pressure reducing valves, designed for the medium with low flow and stable load. The accuracy of direct-acting relief valves is usually +/-10% of the downstream set point.

Direct acting pressure reducing valve

Smaller capacity direct acting pressure reducing valves (Figure 7.3.1)

Method of operation

On start-up and with the adjustment spring relaxed, upstream pressure, aided by a return spring, holds the valve head against the seat in the closed position. Rotating the handwheel in a clockwise direction causes a downward movement, which compresses the control spring and extends the bellows to set the downstream pressure.

This downward movement is transmitted via a pushrod, which causes the main valve to open.

Steam then passes through the open valve into the downstream pipework and surrounds the bellows. As downstream pressure increases, it acts through the bellows to counteract the adjustment spring force, and closes the main valve when the set pressure is reached. The valve plug modulates in an attempt to achieve constant pressure.

In order to close the valve, there must be a build-up of pressure around the bellows. This requires an increase in downstream pressure above the set pressure in proportion to the steam flow.

The downstream pressure will increase as the load falls and will be highest when the valve is closed. This change in pressure relative to a change in load means that the downstream pressure will only equal the set pressure at one load. The actual downstream pressure compared to the set point is the proportional offset; it will increase relative to the load, and this is sometimes referred to as ‘droop’.

The total pressure available to close the valve consists of the downstream pressure acting on the underside of the bellows plus the inlet pressure acting on the underside of the main valve itself and the small force produced by the return spring. The control spring force must therefore be larger than the reduced pressure and inlet pressure and return spring for the downstream pressure to be set.

Any variation in the inlet pressure will alter the force it produces on the main valve and so affect the downstream pressure.

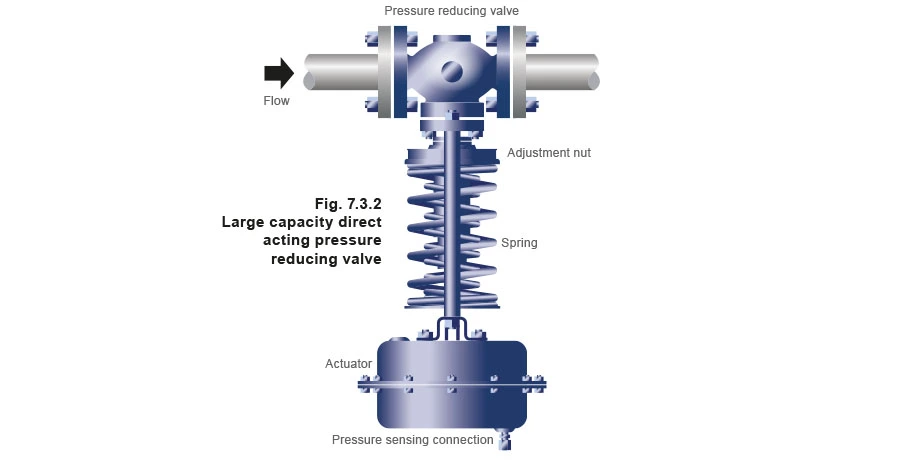

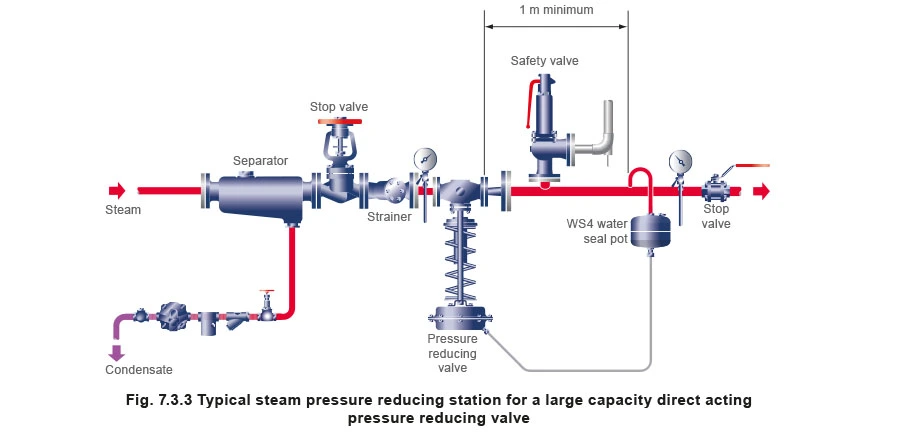

Larger capacity direct acting pressure reducing valves (Figure 7.3.2)

Larger capacity direct acting pressure reducing valves are also available for use on larger capacity plant, or on steam distribution mains. They differ slightly to the smaller capacity valves in that the actuator force is provided by pressure acting against a flexible diaphragm inside the actuator rather than a bellows.

As these are not pilot-operated, they will incur a change in downstream pressure as the steam flow changes, and this should be taken into careful consideration when selecting and sizing the valve.

This type of valve is installed with the actuator below the pipe when used with steam, and has a water seal pot to stop high steam temperatures from reaching and damaging the actuator’s flexible diaphragm, which is commonly made out of neoprene. A typical installation for the reduction of steam mains pressure is shown in Figure 7.3.3.

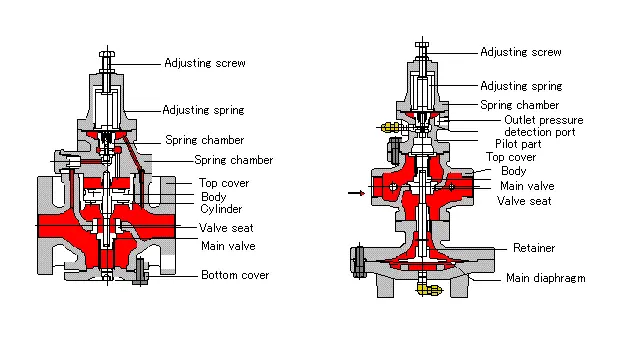

Pilot-operated valves

Where accurate control of pressure or a large flow capacity is required, a pilot-operated pressure reducing valve can be used. Such a valve is shown schematically in Figure 7.3.4. A pilot-operated pressure reducing valve will usually be smaller than a direct acting valve of the same capacity.

A pilot-operated pressure reducing valve works by balancing the downstream pressure via a pressure sensing pipe against a pressure adjustment control spring. This moves a pilot valve to modulate a control pressure. The control pressure transmitted via the pilot valve is proportional to the pilot valve opening, and is directed, via the control pipe to the underside of the main valve diaphragm.

The diaphragm moves the pushrod and the main valve in proportion to the movement of the pilot valve. Although the downstream pressure and pilot valve position are proportional (as in the direct acting valve), the mechanical advantage given by the ratio of the areas of the main diaphragm to the pilot diaphragm offers accuracy with small proportional offset.

The pilot on a pilot-operated regulator is simply a direct-operated regulator so it is constrained by the same droop issue; however, pilots don’t have to travel very far. When downstream demand is zero, the pilot is closed, making loading pressure equal to outlet pressure. Then, when downstream demand increases, the pilot opens allowing high pressure to flood into the loading chamber. The pilot responds to the small decrease in outlet pressure and sends the main valve a greatly amplified signal via the loading pressure change. This pressure amplification from the pilot is called gain.