What is Valve Seat and Seat Rings, How Many Different Materials Does They Have ?

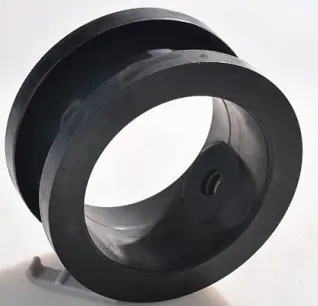

The Valve seat or seat ring is used to support the valve plug or disc in a fully closed position and to form a sealing part. Usually the valve seat diameter is the maximum flow diameter of the valve.Seat material is very wide, all kinds of rubber, plastic, metal materials can be used as seat material, such as EPDM, NBR, NR, PTF.E, PEEK, PFA, SS315, STELLITE and so on

- Rubber Valve Seat PTFE Valve Seat Metal Valve Seat

For butterfly valve the seat material usually are rubbers , such as EPDM , NBR , NR (Natural hard rubber)

For ball valve and plug valve the seat material usually are plastics , such as PTFE , PEEK and so on .

For gllobe valve and gate valve the seat material usually are metal to metal .

For valves using soft seat material their shut-off performance is great , and even can reach zero bubble seat tightness . while the disadvantage part is they can not resisit with high tempreature and high pressure application .

On the other hand , for those valve's seat material is metal to metal therefore they can stand with high pressure rating up to 2500LB .

Important factors affecting a valve’s shut-off performance could be the nature of media being handled. The service life of valves is affected by all of the following factors:

- Pressure and Pressure Fluctuations

- Type and Velocity of the Media

- Temperature and Temperature Fluctuations

- Valve Cycling Frequency and Operation Speed

- Industrial Valve Seals and Seats materials are generally manufactured using the following materials:

BUNA-N (HYCAR orNitrile)

Buna-N is a general-purpose polymer which has good resistance to oil, water, solvents and hydraulic fluids. It also displays good compression, abrasion resistance, and tensile strength. This material performs extremely well in process areas where paraffin base materials, fatty acids, oils, alcohols or glycerin are present, since it is totally unaffected.

Buna-N should not be used around high polar solvents (acetones, ketones), chlorinated hydrocarbons, ozone or nitro hydrocarbons. Temperature range is 107°C maximum. Hycar is black in color and should not be used where discoloration cannot be tolerated. It is regarded as a comparable replacement neoprene. Major differences are: Buna-N has a higher temperature limit; neoprene is more resistant to oils.

CARBON FILLED TFE

Carbon filled TFE is an excellent seat material for steam applications as well as high effeciency oil-based thermal fluids. Fillers including graphite enable this seat material to have a better cycle life than other filled or reinforced TFE seats. Temperature range is -29°C to 260°C. Chemical resistance is equal to other TFE seats.

DELRIN ®

Delrin is DuPont’s trademark for Polyoxy-methylene. It may also be known as Hostaform, Celecon, Kepital, Duracon, Lupital or Ultraform. Delrin is very rigid material and does not undergo cold flow. It has an excellent combination of strength, hardness, stiffness, stability, abrasion resistance and low friction. Delrin has high heat resistance and low water absorption, but is susceptible to acids. When used as a seal material, Delrin is acceptable for pressures up to 5,000 PSI. Its operational temperature envelope is -70 ºF to 180 ºF.

EPDM

EPDM is a terpolymer elastomer made from ethylene-propylene diene monomer. EPDM has good abrasion and tear resistance and offers excellent chemical resistance to a variety of acids and alkaline. It is susceptible to attacks by oils and is not recommended for applications involving petroleum oils, strong acids, or strong alkaline.

This Material should not be used on compressed air lines. It has exceptionally good weather aging and ozone resistance. Temperature rating is from -29°C to 107°C (121°C intermittent service). It is fairly good for ketones and alcohols.

HYPALON®

Hypalon has very good resistance to oxidation, ozone and good flame resistance. It is similar to neoprene except with improved acid resistance where it will resist such oxidizing acids as nitric, hydroflouoric and sulfuric acid. Abrasion resistance of Hypalon is excellent, about the equivalent of the nitriles. Oil and solvent resistance are somewhat between that of neoprene and nitriles. Salts have little if any effect on Hypalon.

Hypalon is not recommended for exposure to concentrated oxidizing acids, esters, ketones, chlorinated, aromatic and nitro hydrocarbons. Not to be used in steam service. Temperature rating is from -18°C to 104°C. Seats are white food grade and may be used on food

NEOPRENE

Neoprene is an all-purpose polymer with many desirable characteristics. Neoprene features high resiliency with low compression set flame resistance and animal and vegetable oil resistance. It is principally recommended for use in pulp and paper applications.

Generally, neoprene is not recommended and is attacked by strong oxidizing acids, most chlorinated solvents, esters, ketones, aromatic hydrocarbons and hydraulic fluids. Neoprene is not generally affected by moderate chemicals, fat, greases and many oils and solvents. Temperature rating is from -29°C to 82°C. Seats are black in color and should not be used on bleached paper lines.

PEEK (Polyetheretherketone)

PEEK is a high performance non-porous semi-rigid thermoplastic with excellent resistance to harsh chemicals. Virgin PEEK is naturally abrasion resistant. It has excellent mechanical strength, dimensional stability and is suitable for use in high temperature / high corrosion environments. PEEK is considered a premium valve seat material due to the fact it is unaffected by continuous exposure to hot water and steam. Its operational temperature envelope is -70 ºF to 600 ºF.

PTFE (TFE of Teflon®)

PTFE is the most chemically resistant of all plastics. It also has excellent thermal and electrical insulation properties. PTFE’s mechanical properties are low compared to other engineering plastics, but its properties remain at useful levels over a great temperature range -40°C to 204°C, depending on brand and application.

RTFE (Reinforced TFE)

RTFE is compounded with a selected percentage of fiber glass filler to improve strength and resistance to abrasive wear, cold fl ow, and permeation in molded seats. Reinforcement permits application at higher pressure and temperature than unfilled TFE. Typical temperature range is -40°C to 232°C. RTFE should not be used in applications that attack glass, such as hydrofluoric acid and hot strong caustics.

TFM1600

TFM1600 appears on our Valve Seals and Seats list because it is a modified version of PTFE that maintains the exceptional chemical and heat resistance properties of PTFE, but has a significantly lower melt viscosity. The result is reduced cold flow, porosity, permeability and void content. Surfaces are smoother and reduce torques. The theoretical service range for TFM1600 is -200°C to 260°C.

TFM1600+20%GF

TFM1600+20%GF is a fiber glass reinforced version of TFM1600. Similar to RTFE, but with the benefit of TFM1600, the glass filled version provides greater abrasion resistance and improves stability at higher pressures.

TFM4215

TFM4215 is an elector graphitized carbon filled TFM material. The added carbon improves stability for higher pressure and temperature combinations.

UHMWPE (Ultra-High Molecular Weight Polyethylene)

UHMWPE is a durable, long-wearing, abrasion / corrosion resistant material. It is also known as High Modulus Polyethylene (HMPE) or High Performance Polyethylene (HPPE). Also, It meets FDA and USDA acceptance for food and pharmaceutical equipment and is a good performer in applications up to 180°F when periodically cleaned with live steam or boiling water to sterilize.

UHMWPE is ideal for low-radiation service and meets the requirements for the tobacco industry where TFE is prohibited. It is highly resistant to corrosive chemicals, with the exception of oxidizing acids and organic solvents. Its operational temperature envelope is -70 ºF to 180 ºF.

VITON® (Fluorocarbon, FKM, or FPM)

Fluorocarbon elastomers are inherently compatible with a broad spectrum of chemicals. Because of this extensive chemical compatibility which spans considerable concentration and temperature ranges, fluorocarbon elastomers have gained wide acceptance as a material of construction for knife gate valve seats.

Fluorocarbon can be used in most applications involving mineral acids, salt solutions, chlorinated hydrocarbons and petroleum oils. It is particularly good in hydrocarbon service. Temperature rating is from -29°C to 149°C. Color is gray, black or red and may be used on bleached paper lines.

VITON is not suitable for steam or hot water service, however, in O-ring form, it can be acceptable for hydrocarbon lines mixed with hot water depending on the type/brand. For seat materials FKM can offer more resistance to hot water.