What is Plug Valve ?

What is Plug Valve?

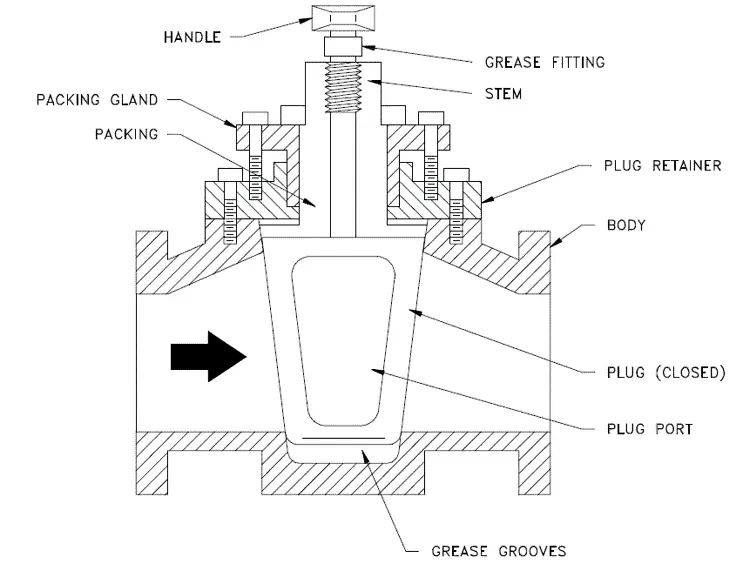

Plug valve is Quarter-turn rotary motion Valve that utilizes a tapered or round plug to prevent or start the flow. The disk is within plug shape, with a passage to pass through the flow. In open position, this bored passage is using the flow. Once the plug is switched 90° in the open position, the solid area of the plug blocks the flow.

Plug valve can be used instead of gate valve in which a quick operation is needed. You can use it in high-pressure temperature services.

Plug Valve Parts

Typical plug valve is composed of body, bonnet, stem and plug. The seat is an essential part from the body in situation of lubricated plug valve. For non-lubricated plug valve, a non-metallic seat can be used to enhance leak tightness from the valve.

Plug valve disk: Plugs are either round or taper cylinder. They may have various types of port openings, each with a varying degree of the opening area.

Plugs are available with

- Rectangular Port

- Round Port and

- Diamond Port

Below in the photo are the list of taper plug with Rectangular, Round, and Diamond Port design.

- Rectangular Port is the most common for plug valve. The rectangular port represents at least 70% of the corresponding pipe’s cross-sectional area.

- Round port plug has a round opening through the plug. It is available in full bore and reduced bore design. Valves with reduced ports are used only where restriction of flow is not important.

- Diamond Port plug has a diamond-shaped port through the plug. All diamond port valves are venturi restricted flow type. This design is for throttling service.

Types of Plug Valves

Plug valves can devide into lubricated tyoe or non-lubricated type and with different styles of port openings through the plug.

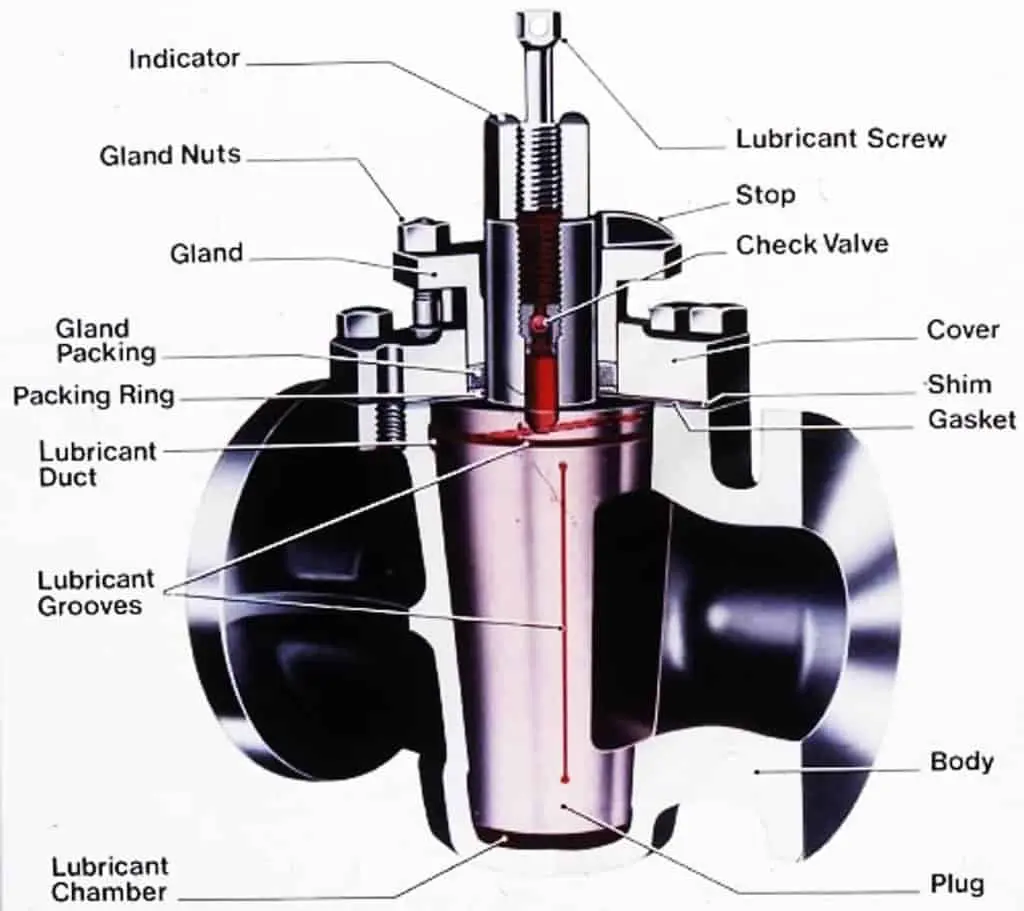

Lubricated Plug Valve

The plug inside a lubricated plug valve includes a cavity in the centre along its axis. You can observe this within the image. Lubricant chamber at the end and also the sealant injection fitting at the very top make sure the way to obtain lubricant.

Small check valve underneath the injection fitting prevents the sealant from flowing within the reverse direction when the sealant is injected in to the cavity.

Plug surface will get constantly lubricated through the sealant that moves in the center cavity through radial holes into lubricant grooves around the plug surface. Now why we needed all of this? Many plug valves have all metal construction.

The narrow gap round the plug may allow leakage, and when you lessen the gap further, it will raise the friction and plug could get stuck within the valve body.

The lubricant cuts down on the pressure needed to spread out or close the valve and enables smooth movement from the plug. The lubricant also prevents corrosion from the plug.

The lubricant material should be suitable for the fluid from the pipeline. It shouldn't dissolve or wash away through the flow medium because this could contaminate the fluid, and damage the seal between your plug and the entire body, leading to leakage. Also, the sealant used must have the ability to withstand a temperature from the flow medium.

Lubricated plug valves can be found in the big size range, and they're fit to operate in high-pressure temperature services. These valves are susceptible to less put on and supply better corrosion resistance in certain service environments.

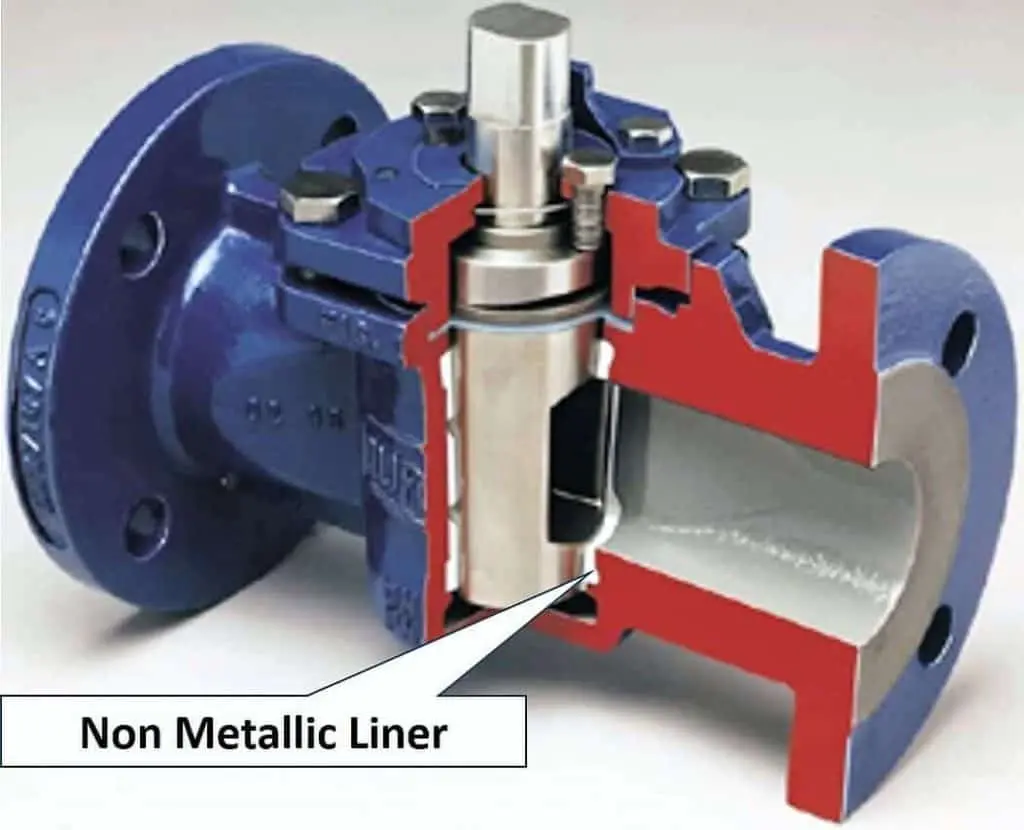

Non-lubricated Plug Valves

A non-metallic elastomeric sleeve or liner can be used in this kind of plug valve. This sleeve is installed in your body cavity from the valve. The polished tapered plug functions like a wedge and presses the sleeve from the body.

This nonmetallic sleeve cuts down on the friction between your plug and also the valve body. Non-lubricating plug valves needed minimum maintenance. Because of the non-metallic seat, these valves aren't utilized in high-temperature services.

Lubricating and non-lubricating plug valves can handle supplying a bubble-tight shutoff and therefore are of lightweight.

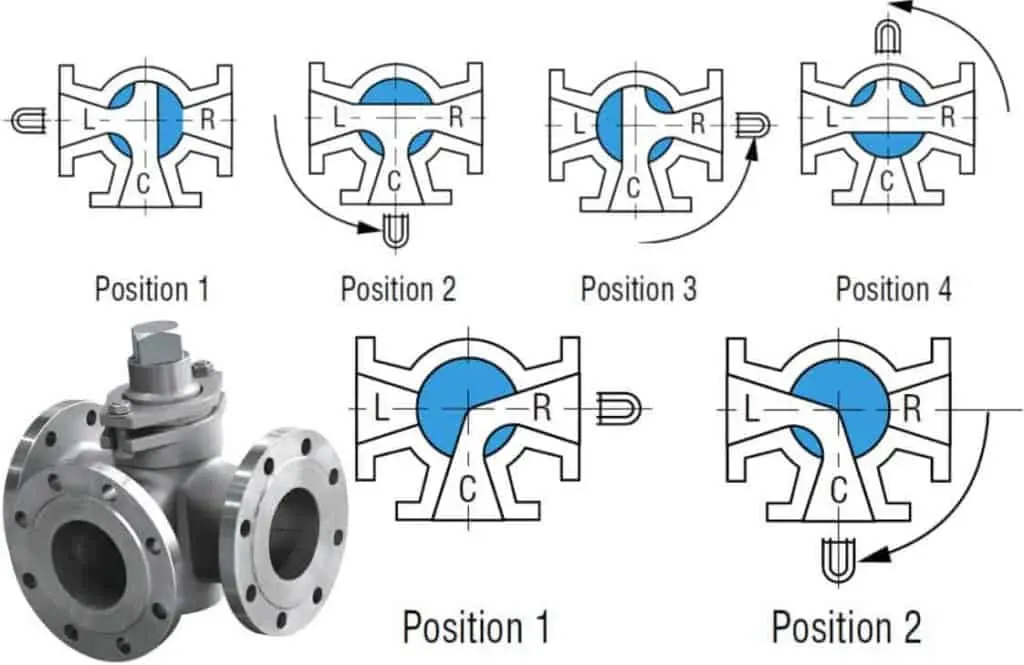

Multi-Port Plug Valves

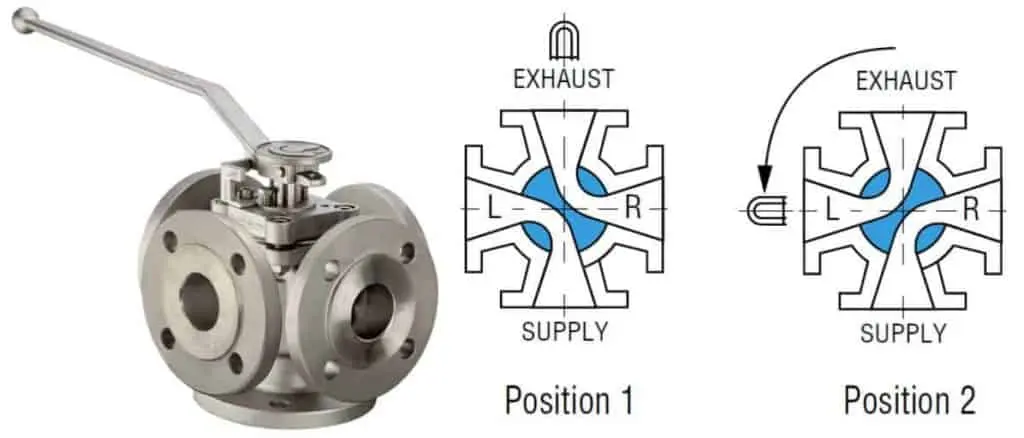

Below is the photo of 3-way multiport plug valve. The top image is of 3-way 3-port design and bottom is 3-way 2-port design.

This is 4-way design.

Multiport valves are utilized in transfer lines as well as for diverting services. Just one multiport valve may satisfy the requirements of 3 or 4 gate valves or other kinds of the shutoff valve. However, sometime multiport valve doesn't completely turn off flow. Great care ought to be drawn in indicating the specific port arrangement for correct operation.

Plug Valve Application

- Plug valve used as on-off stop valves and capable of providing bubble-tight shutoff.

- It can be used in different types of fluid services such as Air, gaseous, vapor, Hydrocarbon, slurries, mud, and sewage applications.

- Plug valve can be used in a vacuum to high-pressure & temperature applications

Pro Side of Plug Valve

- Simple design with few parts

- Quick to open or close

- inline maintenance possible

- Offers minimal resistance to flow

- Provides reliable leak-tight service

- Multiple port design helps reduce the number of valves needed and permits a change in flow direction

Con Side of Plug Valve

- It requires greater force to operate, due to high friction

- Larger valves cannot be operated manually and required an actuator

- Pressure drop due to reducing port

- Cost of Plug valves may be more than ball valves for given size and class

Click This Link To Get To Know More About Our Plug Valve Product Ranges