What is a Metering Pump (dosing pump)?

A metering pump is used to add small but accurate volumes of a liquid to other fluid streams or vessels. Metering pumps are also called dosing pumps and proportioning pumps. A metering pump must be able to deliver liquid with an accuracy of greater than 3% across a wide range of discharge pressures.

What applications use metering pumps?

Common types of metering applications are:

- Maintaining a constant flow rate regardless of differential pressure or fluid viscosity.

- Delivering a variable flow to maintain a system parameter (for example, pH).

- Injecting a discrete dose (typically required in batch processing).

What type of pumps are used for metering?

With applications delivering low viscosity liquids at high flow rates (> 1 m3/h) and low delivery pressures it is possible to use a centrifugal pump to achieve a controllable flow. This can be the most cost-effective solution. However, in other situations, accurate metering necessitates the use of a positive displacement pump. This class of pump moves a fluid by repeatedly enclosing a fixed volume, with the aid of seals or valves, moving it mechanically through the system. The pumping action is cyclic and by controlling the motor's speed or stroke length, a specific delivery rate or accurate single dose is possible.

Traditionally, reciprocating pumps employing plungers, pistons or diaphragms are used for metering and dosing duties. These pumps have the inherent ability to maintain a consistent flow rate over a wide and varying pressure range. However, with recent advances in electronics and control technology, other designs, such as peristaltic pumps or gear pumps can also be used.

What are the advantages and disadvantages of piston pumps & plunger pumps?

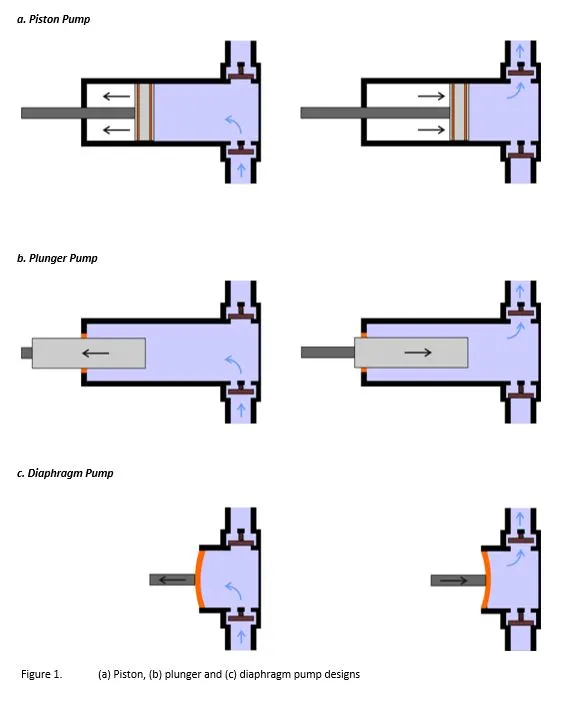

With a piston pump, a defined volume of liquid is drawn into the pump on the suction stroke and delivered on the compression stroke (Figure 1a). With a plunger design, the volume of fluid moved by the pump depends on the plunger size (Figure 1b). In both cases, the volume of liquid delivered is known precisely. However, the reciprocating action means that no fluid is delivered during the suction stroke of the pumping cycle. This creates pulses in the discharge with the fluid accelerating during the delivery phase and slowing during the suction phase. Pulsation can cause damaging vibrations in the discharge system and often some form of damping or smoothing is employed. Pulsing can also be minimized by using additional, out of phase, pistons or plungers. The efficiency of the seal around the piston or plunger is important in maintaining the pumping action and to avoid leaks.

What are the advantages and disadvantages of diaphragm pumps?

A diaphragm pump uses a flexible membrane instead of a piston or plunger to move fluid (Figure 1c). By expanding the diaphragm, the volume of the pumping chamber is increased and fluid is drawn into the pump. Compressing the diaphragm decreases the volume and expels some fluid.

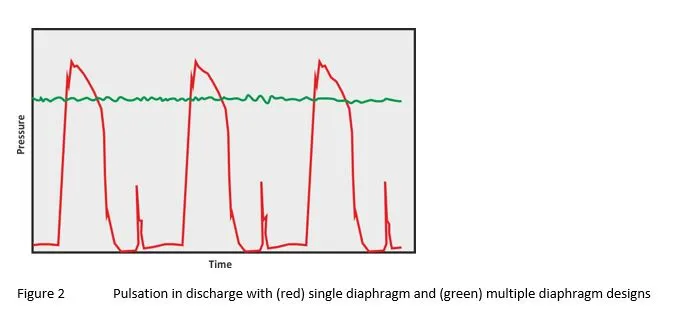

Diaphragm pumps have the advantage of being hermetically sealed making them ideal for pumping hazardous fluids. However, the accuracy of delivery is dependent on the performance of the discharge and suction side valves and the extent of any backflow. Diaphragm pumps also suffer from pulsation in the discharge although this is reduced by having two (or more) diaphragms with one in its compression phase whilst the other is in suction (see Figure 2). A design using this approach is the air-operated double diaphragm pump (AODD). With flows below 10 m3/hr, and where an accuracy of 3% is acceptable AODDs are a relatively low cost and reliable metering solution capable of operating at up to 10 bar. They can be run dry and cope with dirty/contaminated liquids. AODDs are typically used as metering pumps in the water industry for injecting additives and in the food industry for adding colouring and cleaning agents.

What are the advantages and disadvantages of peristaltic pumps?

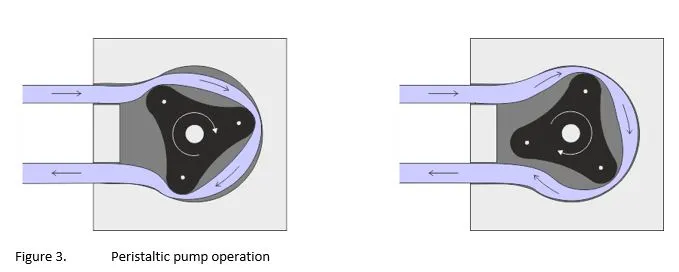

A peristaltic pump delivers fluid by mechanically squeezing a space enclosed by a flexible element. A common type operates by means of rollers acting directly on a hose containing the liquid (Figure 3). Peristaltic pumps are used extensively as metering pumps in laboratory and medical applications but advances in materials technology have led to heavy duty pumps capable of dealing with highly viscous fluids, sludges and slurries in a wide range of industrial applications.

The advantage of peristaltic pumps is that the pumped fluid is always contained and never in contact with the pump mechanism. This makes it ideal when hygiene is important, for example, in medical applications and food processing. Peristaltic pumps can also handle solids. Wear of the flexible elements can be an issue, and these should be replaced regularly to avoid the possibility of failure. The cyclic pumping action creates pulses in the discharge although this can be reduced by introducing additional hoses and pumping elements.

Peristaltic pumps are generally limited to discharge pressures up to 10 bar and flow rates between 0.001 l/hour and 50m3/hour are typical. They are often employed in research laboratories, chemical processes and for the introduction of thick slurry type additives (for example, lime dosing in the water industry).

What are the advantages and disadvantages of gear pumps?

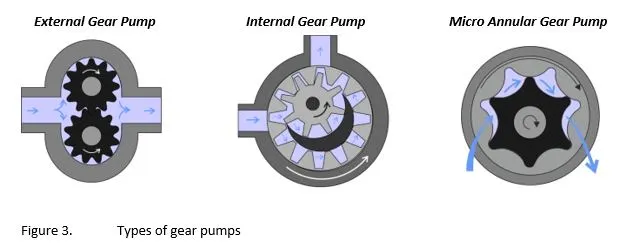

Gear pumps use the actions of rotating cogs or gears to transfer fluids (Figure 4). The rotating element develops a liquid seal with the pump casing and creates suction at the pump inlet. Fluid, drawn into the pump, is enclosed within the teeth of its rotating cogs or gears and transferred to the discharge.

Gear pumps have many advantages over piston-driven solutions. They can withstand high operating pressures and can be used for applications involving high viscosity fluids. They are simple and low cost, and accuracies of 0.5% are achievable. Gear pumps deliver fluid without the surging pulses observed with piston-based pumps and have lower pulsations than diaphragm pumps. This simplifies system design (pulsation dampeners are not required), aids accurate flow measurement, and means lower NPSH requirements. When gear pumps are fitted with a hermetically sealed magnetic coupling,, the problems of fluid leakage can be eliminated.

Gear pumps rely on the close tolerances between the gears, bearings and casing and this can be affected by an abrasive feed. Wear, and consequently leakages, can occur around the gear teeth, across the face of the gears and around the bearings. As wear increases, there is a gradual reduction in efficiency and increase in flow slip: leakage of the pumped fluid from the discharge back to the suction side. Flow slip is proportional to the cube of clearances within a pump and so can have a significant effect on pump output. When this occurs, metering accuracy is affected.

Gear pumps are frequently used in fine chemical, medical and pharmaceutical applications for delivering chemically reactive materials and for metering additives at high pressure in plastics, rubber and polyurethane industries.

What is API 675?

API 675 is an industry standard defining the minimum requirements for reciprocating, metering pumps for use in the petroleum, petrochemical, and gas industries. It applies to pumps that are either hydraulic diaphragm or packed plunger designs. Rotary pumps and diaphragm pumps that use direct mechanical actuation are not included.

What is a Variable Speed Drive (VSD)?

Traditionally, reciprocating metering pumps are controlled by varying the motor stroke length so that the pump supplies the required flow rate. This approach allows the drive motor to continue running at its optimum speed. Advances in drive and control technology now allow motor speed to be controlled accurately so that pumps can be run more efficiently. Pumps equipped with VSD technology may be more expensive than fixed speed alternatives but the additional cost will soon be recouped from the long-term energy cost saving.

Summary

A metering pump (also called a dosing pump) is used to add small but accurate volumes of a liquid to other fluid streams or vessels. Metering is achieved by controlling the pump's speed or stroke length to achieve a specific delivery rate or by controlling the period of operation to supply an accurate single dose.

Traditionally, plunger or piston pumps, diaphragm pumps or peristaltic pumps are used for metering and dosing duties. With recent advances in electronics and control technology, gear pumps can be used across a wide range of conditions and have the advantages of a virtually pulse-free flow and an ability to work at high pressures with high viscosity liquids.