What Is A Ball Valve

A ball valve is really a rotational motion (quarter turn), quick rotating valve that utilizes a ball-formed disk to prevent or start or regulate fluid flow. The part of this kind of valves, ball is just like of disk in globe valve. Once the valve handle is switched to spread out the valve, the spherical ball rotates to a situation where the opening with the ball is within-line using the valve body inlet and outlet of flow. Once the valve is shut, the ball is rotated so the hole is verticle with respect towards the flow openings from the valve body and also the flow is stopped.

Ball valve actuators have the fast-acting type, which need a 90° turn from the valve handle to function the valve. Some ball valve actuators for example planetary gear-operated, allow using a relatively small operating pressure to function a pretty big valve.

Some ball type valves happen to be developed having a spherical surface coated plug that's off and away to one for reds on view position and rotates in to the flow passage until disk blocks the flow path completely.

Benefits of Ball Valves

- A ball valve may be the least costly associated with a valve arrangement

- Ball valve offers low maintenance costs.

- Ball valves are compact, require no lube, and provide tight sealing with low torque.

Disadvantages of Ball Valves

- Ball type valves (especially old designs) have relatively poor throttling characteristics.

- Inside a throttling position, the partly uncovered seat of ball valve quickly erodes due to the impingement of high velocity flow.

Valve Materials in Ball valves

Balls are often metallic with trim (seats) created from elastomeric (like rubber) materials. Plastic construction in ball valves can also be available.

The resilient seats for ball valves are manufactured from Teflon (TFE), filled TFE, Nylon, Buna-N, Neoprene, other mixtures of this stuff. Due to these elastomeric materials ball valves can't be typically used at elevated temperature and engineer will need to take care while selecting ball valve for particular application.

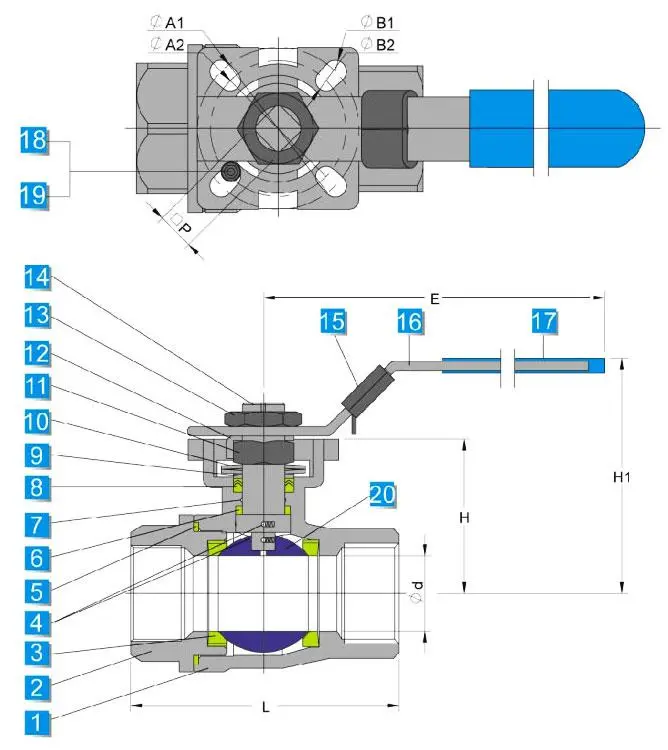

Ball Valve Port Patterns, Bonnet & Stem Design

Ball valves can be found in reduced, and full port pattern. The entire port

pattern includes a ball having a bore comparable to the interior diameter from the pipe.

The stem and ball connection is described here. The stem inside a ball valve isn't attached towards the ball. It commonly has an oblong portion in the ball finish which inserts right into a slot reduce the ball. The enlargement permits rotation from the ball because the stem is switched. A bonnet cap fastens towards the body, which supports the stem set up and ball in position. Adjustment from the bonnet cap permits compression from the packing, which gives the stem seal. Packing for ball valve stems is generally within the configuration of die-created packing rings normally of TFE, TFE-filled, or TFE-impregnated material. Some ball valve stems are sealed by way of O-rings instead of packing.

Ball Valve Positions

Some ball valves are outfitted with stops that enable only 90° rotation. Others don't have stops and could be rotated 360°. Whether there's stop available or otherwise, a 90° rotation is that's needed for closing or opening a ball valve.

The handle signifies valve ball position. Once the handle lies across the axis from the valve, the valve is open. Once the handle lies 90° over the axis from the valve, the valve is closed. Some ball valve stems possess a groove decline in the very best face from the stem that shows the flow path with the ball. Observation from the groove position signifies the positioning of the port with the ball. This selection is especially beneficial on multiport ball valves.

Click This Link To Get To Know More About Our Ball Valve Product Ranges