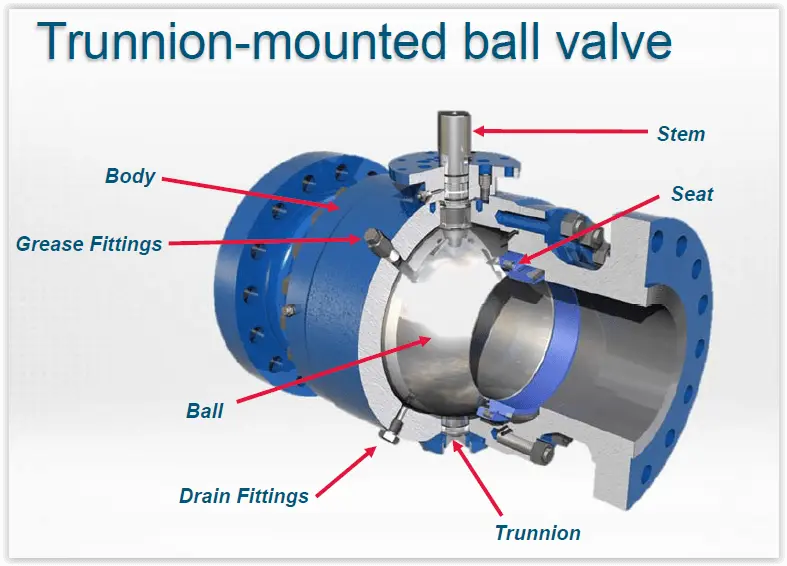

Trunnion Ball Valve Detailed Introduction

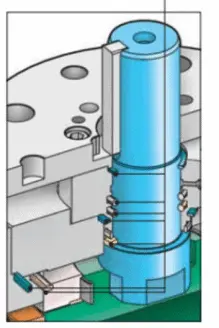

The ball valve is an essential device for regulating the flow of fluids- steam, gas, or oil in pipeline. It is quarter-turn designs with a ball capable of rotating 90 degrees on its axis to either block or allow the flow of fluid. These valves have a spherical disk design at the center, which rotates to regulate the start-stop flow cycle. The disk often called the ball comes designed with a small protruding shaft at the top and bottom which are mechanically supported. In this case, flow is controlled by the position of a hole in the center of the ball. For their versatility, Trunnion mounted ball valves are useful in industries where such shut-off operation is required.

The Trunnion ball valves have adequate backing for the ball. The support is in shape similar to a shaft, and it's called a trunnion. The Trunnion soaks up any additional pressure coming from the flow, thereby lowering the pressure on the valve seat and the ball. Trunnion mounted ball valves find their use in large-scale implementations that require low operating torque.

2. How Does a Trunnion Ball Valve Work

Trunnion valve is a device that controls the flow of fluids in pipelines by regulating the shut-off cycle. It contains the elements necessary for enabling or disabling the flow of fluids through the pipe. It is built to integrate pipe or tube sections to actualize this function.

3. What Is The Structure Of Trunnion Ball Valve

The Trunnion ball valves have a structure similar to the traditional ball valves seen around. The difference it brings is that the ball valves have more mechanical anchors to support the ball. The ball is given solid support from the two ends on its x-axis. It holds it in place and makes it very easy to control.

In the trunnion mounted ball valve, the design comes with dismal tended shafts at its top and bottom, which are mechanically supported. With this, it is made suitable for larger diameters and higher pressure. In the Trunnion mounted design, the ball is kept in position by compressing the seat rings at the two ends.

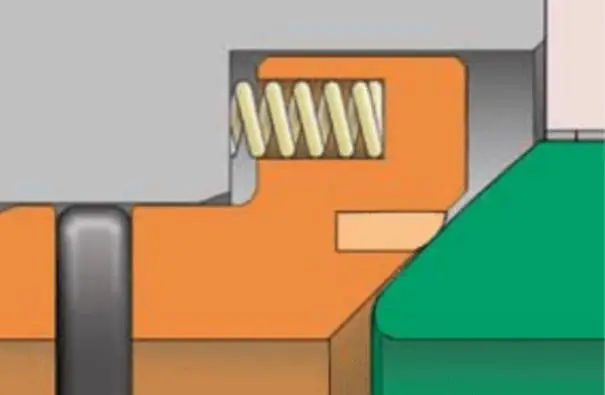

The ball, for its flexibility, enables a good measure of movement. While in use, it floats moderately downstream towards the seat ring to make a sealing. If the loads on the floating ball are much higher, the seat rings won't be able to give the needed support to the ball. This is when the power of the trunnion comes in. In a trunnion design, the seat rings are the parts floating against the traditional design where the ball floats.

Body

The valve's body is the casing that holds it in place and offers support to the interior of the ball valve. The material for this design can be made of different products depending on the type of application it is used for. Some of the commonly used materials are carbon steel, low-temperature carbon steel, stainless steel, duplex, Inconel, and super duplex.

Ball

This is a sphere ball shaped disk through which it rotates to stop or start flow in a solid rotational motion. It is connected to the Trunnion at one end and the stem at the other end. The ball is fixed in a position while it rotates. The trunnion ball valve's seats are often in contact with this ball, which reduces the torque.

Seat

The seat of the Trunnion ball valve is a design feature that surrounds the ball. When the actuator gets turned on, the seats keep the ball tightly in place, blocking off access. There are two types i.e. metal or soft (Teflon). This makes it move in the direction of the ball.

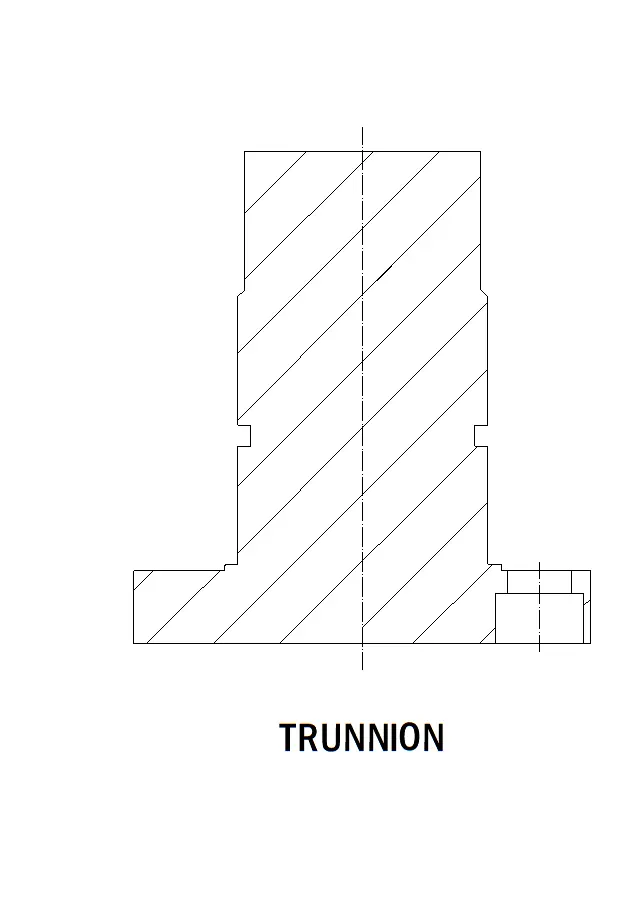

Trunnion

There is an extra shaft in the trunnion ball valve that grips the ball in position from beneath. This simple shaft is the Trunnion. Its function is to keep the ball firmly attached. Sometimes, the Trunnion is an extension of the spherical ball, whereas, in other trunnion-mounted ball valves, it is attached to the spherical ball disk via welded joints.

Stem

The stem of the trunnion ball valve helps connect the ball and the actuator together. It is connected to the ball an additional shaft that helps secures the ball in place. Also, it regulates the ball's movement. Trunnion-mounted ball valves have strengthened anti-blowout stems, which is why they are able to handle pressurized and intense temperatures without causing any damage.

Injection

Injection fittings are designed in the seat and stem area. When sealing is compromised, and leakage is caused, the grease can be injected via a sealant injection fitting. The injected sealant functions as a partial seal to stop further leakage.

However, it must be noted that the sealant injection fittings are for emergency purposes only.

4. Trunnion Ball Valve Design Standard

The trunnion ball valve is designed by API6D or API608, and conforms to industry required standards such as ASME B16.5, ASME B16.34 and ASME B16.10. They are built to be fire resistant according to API 607.

5. Typical Material

The Trunnion ball valve is accessible in forged or cast body materials (split or monoblock). Forged structures are often used for valves of high-pressure and larger bore sizes.

5.1 Typical materials for trunnion mounted ball valve design include:

A. Body/Closures-- F304L, A105, A182 F304, F316, F51, F316L, F53, A350 LF2, LF3, Inconel, Monel, Hastelloy( Forging), A351 CF3, A351 CF8, A216 WCB, A351 CF3M, A351 CF8M, A890 4A/ 5A, A352 LCC/ LCB (Casting).

B. Ball- CS+ENP, F304L, F316, A182 F304, F316L, F51, CS+TCC, CS+N i60, F53.

C. Seat retainer- A182 F304, CS+ENP, F304L, F316, F51, F53, F316L, CS+N i55, CS+TCC.

D. Stem-- A182 F51, A182 F6a, A182 F316, 17-4PH,.

E. Packing- RPTFE, Graphite, PTFE,.

5.2 SEAT MATERIAL.

PTFE: Virgin PTFE is by far the most commonly used sealing material of exceptional quality. It has attributes suitable for most services. It's of outstanding chemical resistance across the valve and also has low friction coefficient.

RPTFE: RPTFE (known as Reinforced PTFE) is usually created by adding 15 percent of fiberglass to virgin PTFE. It has improved pressure-temperature capabilities than the virgin PTFE and comes with enhanced wear resistance. It is effective against deformation when on load.

PCTFE: PCTFE is a chlorotrifluoroethylene homopolymer with high tensile stress and have a low deformation when on load.

Nylon 6: Nylon is a rising seat material for Valves of Class 600. It is extremely robust and can be useful in oil, air, and other media. It is appropriate for strong oxidizing agents.

Devlon: Devlon is a strong molecular weight polyamide especially suited to high temperature and pressure applications in the gas and oil industry. In addition, it is a minimal moisture absorption material.

PEEK: PEEK is an advanced high-performance thermoplastic. It is really good at continuous exposure to hot water and chemicals owing to its high resistance.

PPL: PPL( Polyparaphenylene) is an exceptional seat material which has a low coefficient of friction. It can withstand extreme pressure and also temperature resistant.

TFM: TFM (modified PTFE) is an improved chemical-modified PTFE design with improved properties whilst retaining the proven benefits of conventional PTFE.

Metal: Metal (typically stellite) seats are employed in situations of hydraulic shock, flashing abrasive media, and in extreme situations.

5.3 O-RINGS MATERIAL.

NBR Buna-N: NBR Buna-N (NBR) is a durable and all-purpose polymer of hard water, oil, solvent, and hydraulic fluids.

HNBR: HNBR (Hydrogenated NBR) can be compared to NBR in terms of media stability but comes with much better oxidation and heat stability.

Viton: Viton (fluorocarbon) is an elastomer of fluorocarbons that is compliant with a wide variety of chemical Substances. It produces strong performance in mineral acids, chlorinated hydrocarbons, salt solutions, and petroleum oil.

EPDM: EPDM has good resistance to abrasion and tear, with outstanding chemical resistance to a range of alkaline and acids. This is susceptible to oil, strong acids, and strong alkaline and should not be applied in compressed airlines.

FVMQ Fluorosilcione: FVMQ Fluorosilcione is a fluorinated side-chain silicone polymer chain for better oil resistance. The physical and mechanical properties closely mimic those of silicone.

These and many more some of the typical materials used for the design of the trunnion ball valve.

6. What Is The Main Features Of Trunnion Ball Valve.

There are many features of the trunnion mounted ball valve. Among the major ones are:.

Emergency Seal.

For a trunnion mounted ball valve, it is designed to have a sealant injection at the seat and the stem. In the event of a failed seal, a temporary emergency seal could be achieved via injection sealants.

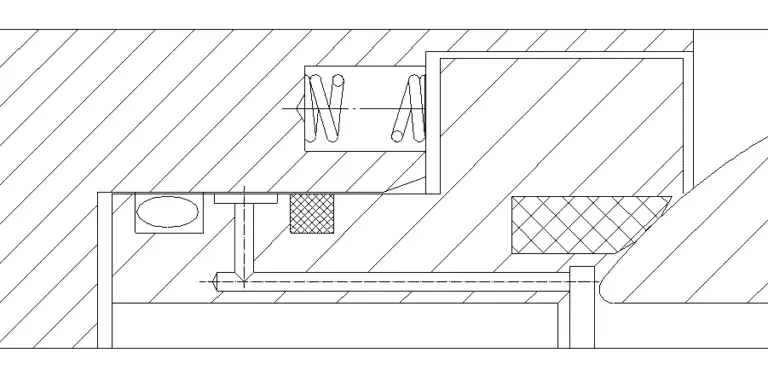

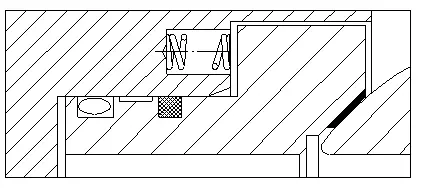

Antic Static.

For the reason that the stem and the ball of a trunnion ball valve are suspended on non-metallic parts, there is the likelihood of a static charge building up on the stem/ball. For this, an antistatic ball and metal spring are included in the design to retain the metal-to-metal contact within the rotating stem or ball and the valve body that helps to ground the charges to the design's valve body.

Blowout Proof Stem.

The stem of the trunnion valve is made with a shoulder at the end of the bottom. It is secured by the filling box in the event that the stem in certain working conditions mistakenly blows out. There are various designs for this.

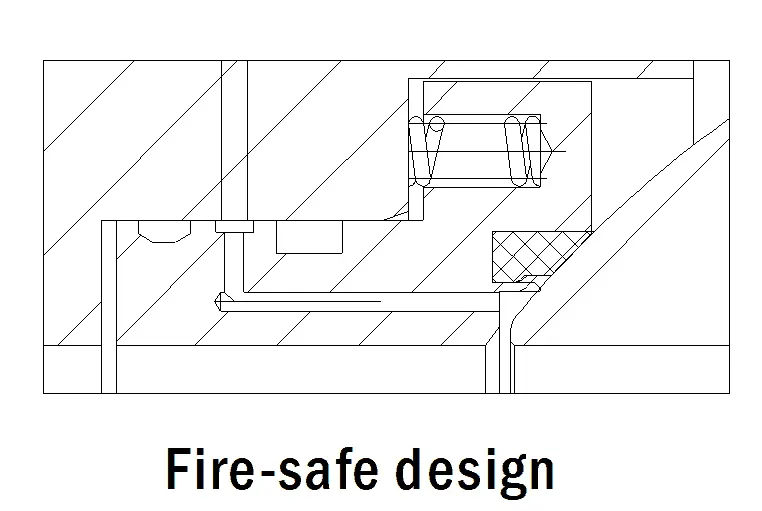

Fire-safe design.

The trunnion ball valve design is tested and certified fire-safe, thus preventing fire spread and prevent environmental pollution. The product is tested and found to be in accordance with API 607 or API 6FA.

7. What Are The Types of Trunnion Ball Valve.

7.1 Based on Body Configuration.

The body configuration features tell how a ball valve can be used and the ease of repairs and maintenance. Based on these parameters, three types of trunnion ball valves will be examined:.

7.1.1. Side Entry Trunnion Ball Valve.

This type of design is also referred to as the split body trunnion mounted ball valve. It assembles its ball from the side. They are often made out of forged metal. In this design, the body is often divided into three or two pieces that are joined together like extensions. A piece of the body is most often bigger than the rest of the design. This larger piece holds the stuffing that winds around the ball and the ball itself. For this design, they are easily repairable and can be inspected as the smaller piece can be pulled out to access the valve.

Advantages.

The design reduces defects commonly associated with a casting design.

They are simple and easy to construct.

They are easy to repair.

Their trim mechanisms are very easy to align.

They offer the advantage of reliable performance, compact envelope, and a cost-effective solution.

They are widely used and so should be readily available.

Disadvantages.

Could be hard to clean.

Throttling causes the partially exposed seat to rust.

7.1.2. Top Entry Trunnion Ball Valve.

This trunnion valve is a unique design that assembles the ball from the top. They are mostly made from casting metal.

The ball valve is designed with a removable bonnet cover atop the ball valve. The interior parts can be accessed easily by removing the bonnet. The valves are easy to disassemble and assemble. The maintenance and repair of the trunnion ball valve can easily be done by pulling it out from the pipeline.

Advantages.

The construction requires minimal thread connection.

Offers an easy structure.

Comes with a small volume.

It is lightweight design.

Offers reliable sealing.

Offers easy maintenance.

Gives easy access to other internals of the valve.

It minimizes leak paths.

Disadvantages.

Possess poor regulating and throttling capabilities due to its design for shutoff and not flow modulation.

It is prone to cavitation.

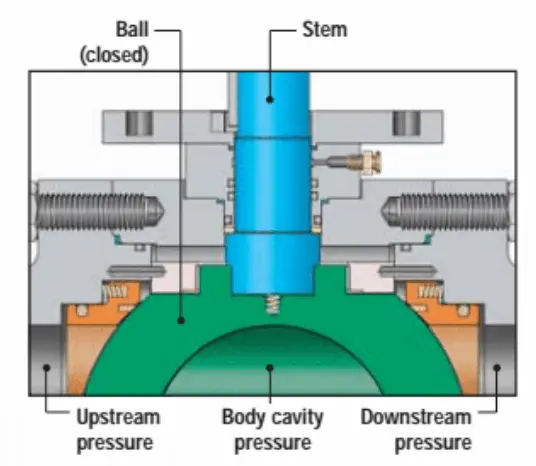

7.1.3. Welded body trunnion ball valve.

This design is mainly an application for the transmission of gas in buried pipelines. They are larger sizes of about up to 60 inches. They have medium pressure classes as much as ASME 900 psi. The RAM material for the design can either be centrifugal casting or forgings. They are made of a variety of materials, including martensitic SS and carbon steels. The valves major technical features include anti-blowout stem and a valve seat design accessible in three various design patterns of:.

DPE (Double Piston Effect): here, the seat may be energized by either upstream pressure or via body cavity pressure.

SPE (Single Piston Effect): In this design, the seat can be energized by upstream pressure and no other.

DUAL (SPE upstream and DPE downstream): It combines the two-seat designs described above. A double blockade can be guaranteed in case of failure of seat sealing.

Advantages.

Has compact built and lesser weight.

Has fewer leak paths.

Disadvantages.

Hard to carry out maintenance for the valve where installed.

7.2 Based On Bore.

A bore in a ball valve is the hole present in the ball's center. There are two types of this design for trunnion ball valves based bore size.

7.2.1. Full Bore.

In the case of full bore trunnion ball valves design, the diameter of the bore aligns with the connected pipeline. When the valve gets opened, the medium could flow with no hindrance from the bore. They are useful in areas or plants where pigging is needed.

Advantages.

They are smaller size designs.

They minimize pressure drop resulting from reduced port valves.

Disadvantages.

They are heavier.

They are more expensive.

7.2.2. Reduced Bore.

A reduced bore valve is a design that has a bore size lesser than the connected pipeline's diameter. The flow path of the channel is limited and results in greater energy loss. They are applicable to the gas and oil industry.

Advantages.

They create a pressure drop in a pipe.

Are smaller in size.

Have a low cost.

Disadvantage.

The hollow ball can trap fluid when in a closed position.

7.3. Based on Sealing Material.

A ball valve comprises two styles of the seat, soft seated, and the metal seated. Soft seat trunnion ball valves are seated using a thermoplastic material such as PTFE and Devlon. Metal seated ball valves make use of metals as seat material like Inconel and Hastelloy. The type of ball valve seat has its own feature and thus has its own advantages and disadvantages.

7.3.1. Soft seat.

Soft seats are typically constructed of thermoplastic substances such as PTFE. They are great for environments where chemical compatibility is necessary and the environment where the tightest seal is essential.

Advantages

Good for clean fluid services

Disadvantages

Not suitable for abrasive media

7.3.2. Metal Seat

The main difference between metal seated valves as against the soft seated trunnion ball valves is its ability to survive high temperatures and harsh service conditions. They can withstand severe hydraulic shock, flashing, abrasive process fluid, and higher temperatures up to and above 1,000 ° F. They are also suitable for use in high corrosion or erosion applications.

Advantages

Excellent corrosion and wear resistance.

Lower torque rate.

Tight shut-off and smooth control.

Stability under pressure and wide range of temperature and pressure.

Can withstand harsh and slurry liquids

Disadvantages

Not field repairable

Heavy design

Have a high leakage rate.

7.4 Based on Body Structure

The valve body of a trunnion ball valve can have one or more pieces joined together through welded joints. There are two kinds of trunnion ball valves based on its number of pieces.

7.4.1. Two Pieces Split Ball Valve

This valve comes with two pieces of the casing that are attached to each other via threaded connections. One piece of the casing can be easily opened to reach the valve for repair or cleaning. However, the valve must be separated from the pipeline; then, the covering can be installed.

7.4.2. Three pieces split ball valve

The three-piece trunnion ball valves are a step ahead of its two-piece version. They've got three bits of the casing that are bolted together. You should remove one section to access the inside of the valve for maintenance and repair. However, there is no need to disconnect the valve from its pipeline to remove it for maintenance.

7.5 Based on Body Material

7.5.1. Forged Ball Valve

Forged steel trunnion ball valves are made using a 'forging' process. Forging is based on thermal energy being applied to solid steel blocks and then using mechanical forces to further process the steel into a finished product. This method is used to produce extremely solid and hard-wearing valves. SIO Forged Steel Valves, for example, are used in mining and mining processing, agriculture and livestock handling, aeronautics, automotive industry, brickworks, stormwater plants, rendering plants, asphalt plants, power and water industries, pharmaceuticals, chemical industry, cosmetics industry and more.

Advantages

Have uniform dimensional tolerance and thickness

Have high intensity and integrity

Have acceptable directional flow path

Disadvantage

Comes with a higher cost

7.5.2. Casting Ball Valve

Casting is a kind of molding by injection, pouring molten liquid metal into the prepared mold. After refrigeration, it shapes castings. Technically, casting can be categorized into sand casting, pressure casting, investment casting, shell casting, casting without a cavity, casting with low pressure, casting with gravity, etc.

Valve casting means that the parts, including frame, and bonnet are cast. Unlike forging, casting makes use of liquid metal to produce valves. Casting is effective in making valves with complex sizes, patterns, and shapes.

Advantages

Are easy to manufacture in complex designs

Comes in lower cost than forged valves

Disadvantages

Susceptible to inter granular corrosion

Have Porosity issues

Suffer sand pockets defects

Suffer stress weakness in high proportion

8. Where is Trunnion Ball Valve Used

The Trunnion ball valves are incredibly versatile. They are used in many different types of industries because of their customizable characteristics. For example, the Trunnion Mounted Ball Valve features O-rings and fire-safe stem packs that prevent leakage. It also comes with stainless steel seal injection fittings for emergency stem or seat sealing. Trunnion mounted ball valves are widely used in the chemical, petrochemical, oil and gas, LNG, and hydrocarbon industries.

They are also used for a variety of applications, including skids such as turbine, compressor, generator and separator, field gas, polymer, LNG, crude oil and industrial gas processing plants, tank farms, automated process applications, hydrocarbon processing, and oil refinery feedstock lines. Trunnion ball valves are suitable for large-scale, high-pressure, and compact, low-temperature applications.

Specific applications include:

Air, gaseous, a and liquid applications

Cooling water & feedwater systems

Steam service

Instrument root valves

9. Why and How to Maintain Trunnion Ball Valves

It is important to keep Trunnion ball valves in optimal performance. This is why the maintenance of all valves is vital. Maintenance of Trunnion ball valves make them available for use in the installation for much longer.

Soft seated valves, while offering the advantages of a quarter turn, are only suitable for clean service. As most of the service is not completely clean, there are maintenance options. As you will see in the case of trunnion ball valves, the use of emergency sealant injection may often attract debris to the seat to further damage it.

Flushing is Necessary

A flushing agent must be used for this reason to facilitate the cleaning. Continuous lubrication is required in the moving parts to prevent rust and wear and tear.

The Trunnion mounted ball valve ensures that the sealant injection facilities have the correct internal control valves and also ensures that the valve is fitted with body, ventilation and drain fittings, packing injectors and lift lines, if necessary. For emergency sealant injection, the shot of synthetic lubricants into the seat and seal area enables the leaking seat to be sealed in an emergency.

The soft seat inserts can be affected by just the slightest amount of pollutants trapped in the fabric.

As mentioned above, flushing agents should be used to remove grease from the seating area, as this may cause more harm to the seat as more debris is attracted.

Construction debris left in the line will wreak havoc on soft seated valves as upstream parts will be contaminated. It is recommended that the line be purged of nitrogen before turning a soft seated valve. By injecting sealant into the seating area, the valve torque can be decreased by up to 40 percent, and many operators choose to retain the synthetic lubricant in the seating area for this.

Repairs and Spraying are Crucial

Spraying is another maintenance method for Trunnion ball valve. Not spraying away impurities from the seat of the valve will increase torque by 80%. This makes emergency shutdown and functional valves a major problem.

Continuous inspection and repairs are necessary to keep a healthy operation in plants. As always, consult an inline valve repair professional as there are various scenarios depending on the operation, size, class & design of the system you are using.

Next: How does a centrifugal pump work?

Previous: How to Calculate Control Valve Cv