The Four Common Types Of Plug Valve

Plug Valve Basics

A plug valve is shaped like a cylinder or cone and can be rotated inside the valve body to control flow of fluids. Plug valves have one or more hollow passageways often placed horizontally to allow ease of flow through the valve when open. The most common type of plug valve is the 2 port type which the ports are usually located on opposite sides of the valve with one passageway leading from inbound to outbound and the stem and handle located on the top. A plug valve is also called a kind of quarter turn valve, which is useful where fast and frequent operation is needed. Flanged ends or butt weld is available for plug valve. there are four common type of plugs valves, each with their own benefits.

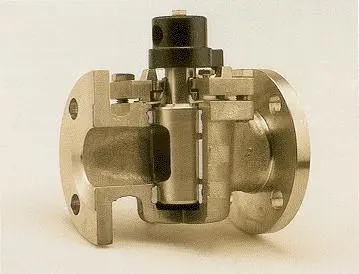

1. Lubricated Plug Valve

As can tell by the name, a lubricated valve uses a lubricant usually made up of a base oil and viscosity improver (like amorphous or fumed silica) that is injected under pressure between the plug face and body seat to reduce friction and seal ports. Valve manufacturers usually suggest lubricant suitable for the process fluid, and the valves often must be resealed after a few cycles, and in some situation, after every cycle. Considered a high maintenance plug valve, they are often used in applications that have infrequent operations. Lubricated plug valves perform very good in processes that utilize fluids which carry mildly abrasive particles such as dirty upstream applications, gas pipeline systems that need bypass valves, and as blow-down valves on valve stations and kicker valves.

Lubricated plug valves are typically used in dirty upstream applications, where contamination of the process fluid is not a cause of concern. The valves are however heavier and more expensive than ball valves. They are also extensively used on gas pipeline systems as bypass valves to mainline ball valves, blow-down valves on valve stations and kicker valves. They can be delivered in exotic materials such as duplex SS and Inconel overlaid.

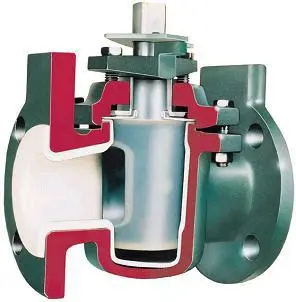

Fig.1: Lubricated Plug Valve

2. Non-lubricated Plug Valve

Non-lubricated plug valves contain a polymeric body liner or a sleeve, which is installed in the body cavity. The tapered and polished plug acts like a wedge and presses the sleeve against the body. The nonmetallic sleeve reduces the friction between the plug and the body. Like for soft-seated ball valves, non-lubricated plug valves are limited by temperature and chemical compatibility of the non-metallic materials used. Non-lubricated plug valves are used instead of lubricated plug valves, where maintenance needs to be kept to a minimum. They can be used in special services (e.g. sulphur and hydrogen fluoride), since they do not have a body cavity in open communication with the flow when switching, where fouling liquids could be trapped or solidify, potentially jamming the valve. These valves are not torque seated.

Fig.2: Non-Lubricated Plug Valve

3. Eccentric Plug Valve

The eccentric plug valve is essentially a plug valve with the plug cut in half. The advantage of this design is a higher seating force with minimal friction encountered from the open to closed position. Shut-off capabilities are improved without a significant increase in operating torque. These valves are torque seated.

The eccentric plug valve has below futures :

a. Cam centric design, lower friction, zero leakage.

b. Welded-in stainless, high end resin seal can meet corrosion resistance needs of numerous medium.

c. The eccentric plug valve has a V type sealing ring could be altered online without disassembling the operator.

d. The eccentric plug valve is Self-lubricated bearing provides super easy operation and occasional operation putting on.

e. Ductile iron plug covered wholly with rubber for drip-tight turn off assures excellent erode and corrosion resistance.

f. O-ring seals provide easy maintenance.

g. Straight line qualities can be used as throttling purpose.

h. Straight through flow design and column form body can meet max. flow capacity needs without deposits.

i. Opening indication provides easy operation.

j. Readily available for manual, pneumatic and electric actuator operation.

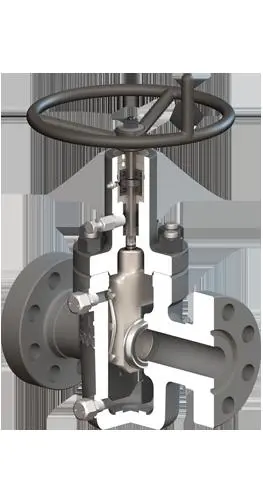

Fig.3: Eccentric Plug Valve

4. Expanding Plug Valve

The expanding plug valve is a special design in which the plug is made of multiple components allowing it to mechanically expand through a wedging action onto the cylindrical body. These valves, although expensive, give a true double block and bleed function in a single valve, and are ideal for preventing product contamination (e.g. in oil movement operations). However these valves shall not be used as a means of “double isolation” for maintenance purposes, as it is still likely that a single failure will affect both blocking functions.

Fig.4: Expanding Plug Valve

Click Plug valve to get to know about our plug valve product ranges .