Safety Valve (PRV) versus. Relief Valve (PSV): What is the Difference?

As we know, there are numerous pressure relief valves available. In the market, we have a tendency to use terms like safety valve and relief valve interchangeably. And typically, this will make sense. Most pressure relief valves are made to perform the same factor - release pressure inside a system.

But what is the distinction between a few of these generally used terms, therefore, exactly what does it mean for you personally? Heres a fast introduction to two popular terms: safety valve versus. relief valve.

Safety Valve versus. Relief Valve: What is the Difference?

While both terms make reference to valves accustomed to release pressure from the pressurized system, their technical definitions really are a bit different. Generally, the word relief valve describes a valve inside a pressurized system which is used to manage pressure for that optimal functionality from the system. Relief valves are made to strengthen your facility avoid system failures, and safeguard equipment from overpressurized conditions.

The word safety valve, however, describes pressure valves that can safeguard people, property, and procedures. Quite simply, the word safety valve describes a failsafe, last measure valve which will release pressure to avoid a catastrophe, usually when other relief valves have unsuccessful to adequately control pressure inside a system.

Do Safety and Relief Valves Perform the Same Factor?

The overall reason for both safety valves and safety valve are identical. Both of them are pressure relief valves, and they're made to let off pressure in almost any situation in which a system becomes overpressurized. That stated, relief valves and safety valves do function slightly differently:

- Relief Valves are made to control pressure inside a system, most frequently in fluid or compressed air systems. These valves open compared to the rise in system pressure. What this means is it normally won't fly completely open once the product is slightly overpressure. Rather, they open progressively, allowing the machine to go back to the preset pressure level. When that much cla is arrived at, the valve shuts again.

- Safety Valves can be used for one good reason - safety. Rather of manipulating the pressure inside a system, they’re made to immediately release pressure in case of an urgent situation or system failure. Unlike relief valves, safety valves open immediately and completely to prevent a tragedy, instead of to manage pressure of the system.

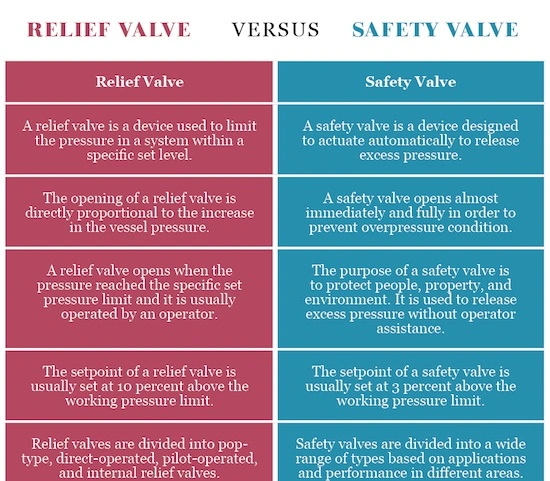

While both safety valves and relief valves try to release excess pressure, how they do it is a touch different. Read this table, thanks to Distinction Between, for a bit more details about the variations backward and forward valves:

Can One Use Safety Valve and Relief Valve Interchangeably?

Now we have a much better knowledge of the technical definitions of both terms, you may be wondering if it is okay to carry on while using terms interchangeably. Generally, industry technicians will know very well what you’re speaking about whichever term you’re using.

If you are focusing on testing both kinds of valves, it’s vital that you comprehend the distinction between these valves, so you realize your facility is sticking towards the proper testing schedule. Otherwise, you shouldn’t need to worry an excessive amount of concerning the exact terminology. Both safety and relief valves are kinds of pressure relief valves, they're just implemented a little differently.

Click This Link To Get To Know More About Our Safety Valve And Relief Valve Product Ranges