LET US DISCUSS THE WAY A TEMPERATURE CONTROL VALVE WORKS

Temperature Control Schemes

There's two popular temperature control schemes using temperature control valves:

(1) Mixing of the cold process fluid having a hot process fluid to manage the temperature from the hot process fluid.

(2) Exchange of warmth between your hot process fluid along with a cold process fluid as observed in heat exchangers. However, the procedure fluids don't mix.

Mixing of Cold and warm Process Fluids

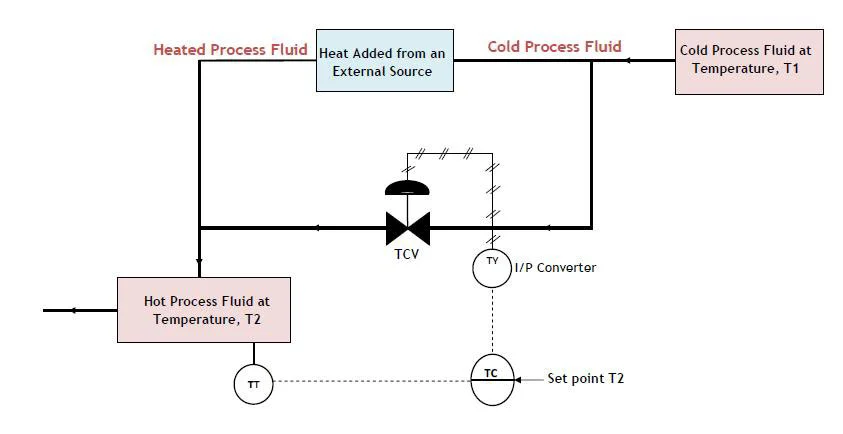

In temperature control valve applications in the most fundamental form, there're two fundamental process fluids:

(a) A chilly process fluid at temperature T1

(b) A warm process fluid, being given through the cold process fluid, to become stored in the preferred temperature T2

As proven above, the temperature control valve is generally positioned or installed such that it may pass cold process fluid to combine track of the new process fluid, therefore, manipulating the temperature from the hot process fluid..It should be noted that mixing in this kind of temperature control is mainly physical and cannot create a chemical reaction for control to become smooth and foreseeable.

Temperature Control Philosophy

To manage the temperature from the hot process fluid with this from the cold process fluid, a temperature sensor/transmitter is set up in the new process fluid. This transmitter measures and transmits the temperature from the hot process fluid to some controller TC (see diagram above) with a set point, T2.

Once the temperature from the hot process fluid goes past T2, the controller through the signal of temperature transmitter TT senses it and transmits an indication towards the TCV to spread out much more that cold process fluid can combine using the hot process fluid, therefore, reducing its temperature. As lengthy because the temperature from the hot process fluid is above T2, the TCV continuously open and introduce more cold fluid using the hot fluid before the set point temperature T2 is achieved.

With this temperature control plan to work, the temperature from the hot process fluid should always be over the set point T2 to ensure that TCV will be open. There are more temperature control schemes using temperature control valves however this is a way in which is extremely famous most process plants.

Exchange of warmth Between Hot Process Fluid along with a Cold Process Fluid

Within the heat exchanger plan of temperature control, mixing doesn't occur what happens is energy transfer between your cold and warm fluid. The new fluid goes through the covering from the exchanger as the cold fluid goes through the tube. The new process fluid transfers heat energy towards the cold process fluid, therefore, growing its temperature. Nevertheless, the elevated temperature from the cold fluid is controlled through the controller TC.

As proven above, exactly the same temperature control philosophy applies here using the temperature transmitter TT sensing the temperature from the cold fluid and transmitting it towards the temperature controller TC. When the temperature from the cold fluid is an above-set point, the controller initiates a control action by delivering an indication towards the temperature control valve, TCV, either to open or near to control the temperature from the cold fluid.

To learn more or to obtain your questions clarified concerning the content above - Send Us An Email sales@shinjovalve.com