HOW YOU CAN SELECT End-Suction Pumps

End-Suction pumps are available in just about any industrial facility and water treatment plant on the planet. Additionally, they're generally utilized in fire protection and Heating and cooling systems, so that as pressure-boosting pumps (booster pumps) in plumbing systems for big structures, for example, big-box stores, stadiums, office structures, and departmental stores.

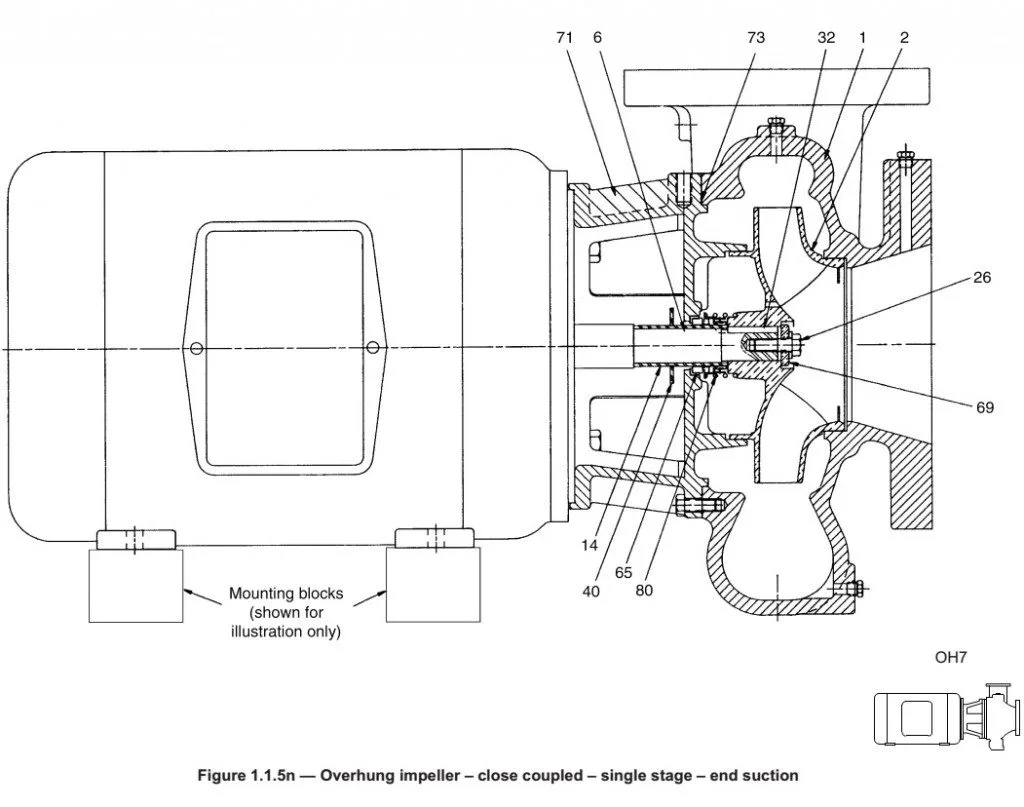

Close-Coupled End-Suction Pumps

Any close-coupled pump, whether from the End-Suction design or otherwise, is going to be created for the impeller to mount directly to the finish from the motor shaft, but for the pump casing to secure straight to the face area from the motor. You will find both pros and cons for this design.

Around the plus side, having a close-coupled pump, the pump and motor never need to be aligned within the field. The pump casing is a registered fit towards the face from the motor making the certain proper alignment. Additionally, close-coupled End-Suction pumps are most likely the most cost-effective kind of pump - they're frequently known as “throwaway” pumps, not always since they're of low quality, but rather since the cost to exchange them is frequently under the price to correct them.

However, close-coupled pumps are available with a minimum of two disadvantages. First, because of the fact the pump is instantly next to the motor, there's an elevated chance of harm to the motor in case of a seal failure. Second, once the unit does require repair, the whole motor should be removed and delivered to a repair center for disassembly, evaluation, and repair.

Close-coupled pumps are often as large as 60 or 75 HP, but no bigger. Motor manufacturers offer motors created for this kind of pump only as much as 60 or 75 HP, along with a bigger motor could be a costly, custom-design having a very long lead time.

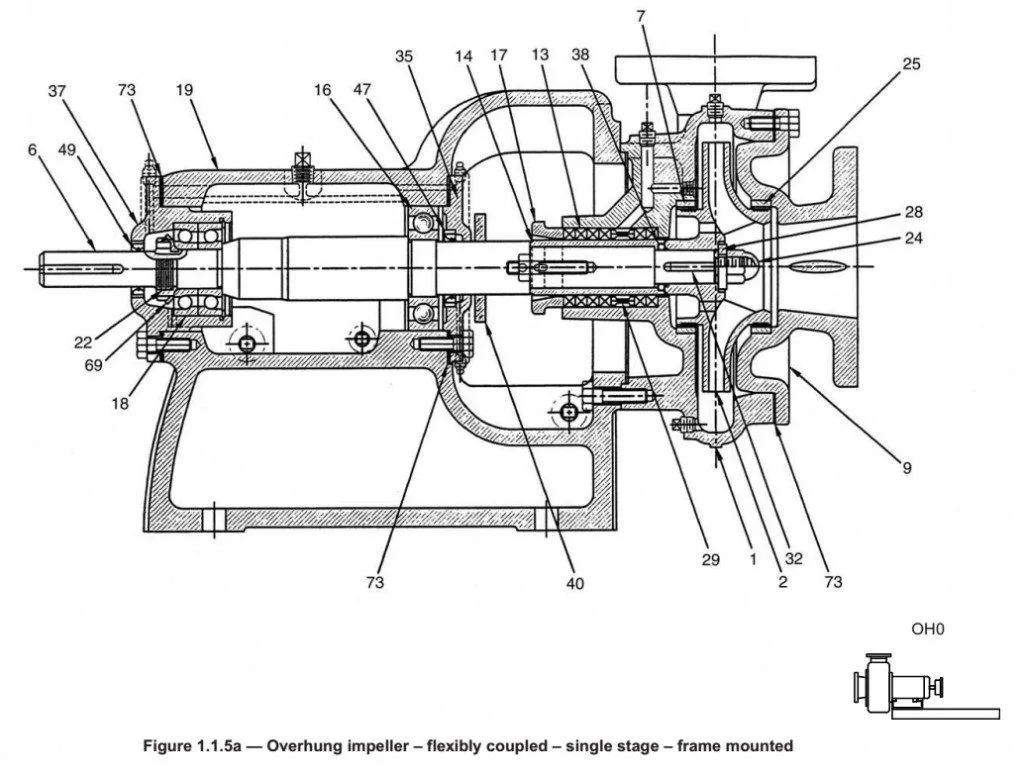

Frame-Mounted End-Suction Pumps

Frame-mounted End-Suction pumps are created to be mounted alongside a person, just like a motor unit, on the common base plate, and coupled plus a flexible coupling. Unlike close-coupled designs, frame-mounted pumps do add a bearing housing. Mounting ft are generally placed directly under the bearing housing or underneath the pump casing to supply support for that pump.

Frame-mounted pumps are generally readily available for applications with power ratings varying from 20 HP as much as 200 HP, even though some manufacturers offer niche End-Suction pumps which are considerably bigger.

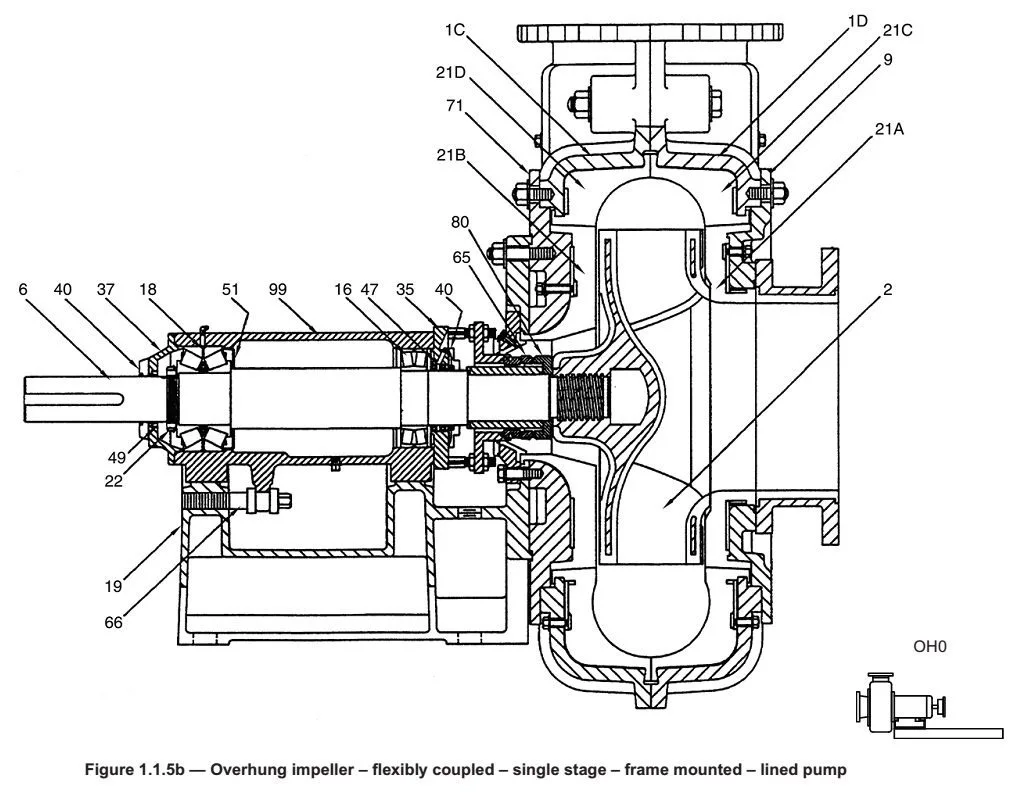

Lined End-Suction Pumps

In lots of industrial and mining applications, the liquid being pump is very abrasive. In these kinds of applications, it frequently is sensible to create a song from the pump for inevitable put on and failure. A lined End-Suction pump is a kind of End-Suction pump made with a replaceable rubber lining. This lining is made to put on out and become replaced with time. Consequently, lined End-Suction pumps can remain operating for extended within the harshest applications.