HOW TO USING PLUNGER PUMPS IN OIL EXTRACTION

Quite simply, plunger pumps use a moving plunger inside a cylinder that serves to displace a set amount of fluid in every operating cycle. Plunger pumps offer a similar experience functioning to piston pumps. But unlike piston models, plunger pumps use a solid round plunger that slides via a high-pressure seal. It is primarily the unique design that enables plunger pumps for use in high-pressure applications, for example for oil extraction.

How Plunger Pumps Are Utilized in Oil Extraction Processes

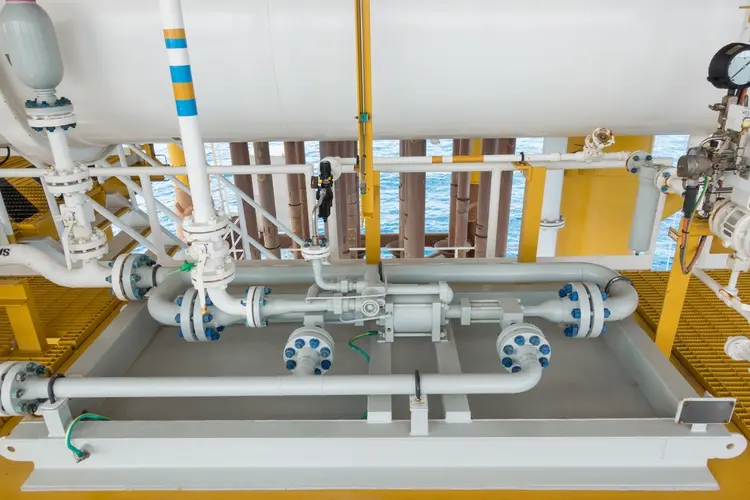

Gas and oil extraction involves numerous high-pressure processes, with suction used to lift fluids and push them into chambers for more processing. Such applications, plunger pumps are frequently employed, because they are well-suited to high-pressure environments. The fluids to become pumped might be sensitive, abrasive, hot, cold, or toxic, and pumps might even be employed to transport flammable or hazardous fluids.

During these situations, specialized, custom-made plunger pumps are frequently a perfect choice. Generally used in the gas and oil industry to function high-pressure water for crude extraction, custom plunger pumps can be created in many sizes and materials to match all kinds of unique application needs. Pumps used to inject high-pressure water for crude extraction, particularly, have a different build and composition than individuals accustomed to lift crude from and into treatment chambers. Being very versatile, these pumps may also be fitted with highly reliable, specialized valves and seals to match use within abrasive or corrosive environments.

Aspects of a Plunger Pump

A plunger pump includes a plunger housed inside a round chamber. The pump is outfitted with valves to manage fluid flow, and extension rods or pony rods are utilized to facilitate piston movement with the chamber. Many of these parts possess a direct effect on the functioning of the plunger pump.

By using materials like stainless and titanium, for instance, a pump valve could be custom-designed for high-pressure or high-speed applications. Pumps may also be made to accommodate high fluid volumes in order to perform reliably even if there's insufficient fluid in the pump inlet port. The pony rods can be created of abrasion-resistant materials and could be custom-suited to match a specific plunger.

The plunger material itself ought to be selected in line with the characteristics from the fluid being pumped. For instance, ceramic-coated plungers are utilized for abrasive fluids, while tungsten-carbide plungers offer protection against deterioration (although not corrosion). Rokide (chrome oxide) can also be frequently useful for pumping fluids with little lube.

Selecting the best Kind of Plunger Pump

Plunger pumps function as reliable, versatile solutions in lots of gas and oil extraction and treatment applications. To make sure you that receive the best, cost-effective pump for the specific job, it’s crucial to utilize a reliable supplier who are able to show you with the buying process. Because of the significant costs which may be incurred because of pump failure in gas and oil extraction, selecting the best model is imperative.