HOW TO FIND A DIAPHRAGM PUMP – AN ENTIRE GUIDE

Diaphragm pumps are a good choice for delivering high volumes of fabric at relatively low pressures. They sometimes resist put on they do not possess a piston moving via a cylinder however a simple rubber diaphragm or diaphragms which are displaced sideways allowing the material to become sent (more about diaphragm versus piston pumps are available here). To have recently made the decision a diaphragm pump is the best choice for the pumping needs, now it's time to learn to correctly pick a diaphragm pump.

Factor 1 to find out for Selecting a Diaphragm Pump – Pump Volume Needs

Diaphragm pumps can pump material varying from the gallon each minute as much as countless gallons each minute with respect to the overall size the diaphragm pump and also the speed where it's operating. An essential fact when selecting a diaphragm pump is to actually attempt to pick a pump which will run at approximately 50% of their maximum potential capacity under normal use. Getting the pump run at 1 / 2 of its maximum capacity will make sure the pump runs for any lengthy time without the necessity of much maintenance. Any diaphragm pump should list its operating capacity in Gallons each minute in both the service manual or around the sales sheet (see below for instance).

Factor 2 in Selecting a Diaphragm Pump – Drive Type for Displacement Pump

There are a number of possibilities they are driving the diaphragm of the diaphragm pump backward and forwards enabling it to function material. Common drive choices for diaphragm pumps include an electric drive or air driven pumps. The drive will become important since it could affect in which the pump will operate and also the when the diaphragm pump could be securely used. Electric drive diaphragm pumps can run anywhere electric can be obtained but they are typically not really a safe solution for places that hazardous amounts of flammable materials can be found (as with paint areas). In comparison, air operated diaphragm pumps work anywhere where compressed air could be presented to drive a diaphragm and therefore are safe even around paints and other alike materials because air doesn't provide an origin of ignition.

Factor 3 when Selecting a Diaphragm Pump - Materials the pump consists of

Diaphragm pumps can be found in a number of material builds. Generally, the most typical options that are offered for diaphragm pump materials range from the material the ball and seat from the pump consist of, and also the material of the pump body consists of. There's a great deal to be looked at however in general common choices for coatings includes stainless ball and seats and PTFE diaphragm materials. Stainless could be more put on resistant but costly while PTFE is less expensive but might not support abrasive materials too. Furthermore stainless are usually more resilient to heat.

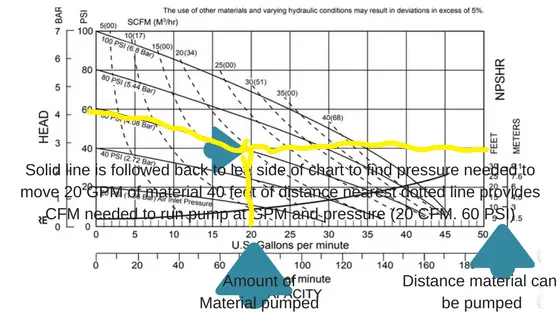

Factor 4 when Selecting a Diaphragm Pump – The Pumps Performance Curve for Air Operated Diaphragm Pumps

Any diaphragm pump has a performance curve which provides you with lots of additional detail around the pump. Common information which a diaphragm pump performance curve will address includes just how much volume (CFM) of air the pump will need at various operating levels and just how much in addition to what lengths material could be provided at the various operating quantity of a pump. Here we took an example pump curve and damaged lower the constituents which are proven. The key factor to understand for the particular diaphragm pump is you have a lot of air for the pump to the function which the pump can deliver material in the rate you would like and also over the space you have to deliver material. Including the chart below shows a pump performance curve. Around the right side from the chart may be the distance you need to move material, around the left side may be the pressure the pump will have to be run at, across the bottom may be the gallons each minute of fabric you will need to deliver. You'll pick a distance you have to deliver material over (within our example 40 ft), then you'll select the number of GPM you have to deliver (20 within the example). Next progress from GPM to obtain the solid line that corresponds with pumping material the space you would like it to be moved. This line is going to be curved and you'll stick to the curve left to obtain the pressure needed to provide material confirmed distance in a given GPM. Within our example to maneuver 20 GPM of fabric with this particular pump over 40 ft will need 60 PSI. Finally, you'll locate the closest curved dotted line around the diaphragm pump curve to obtain the CFM needed with this degree of performance which may be 20 CFM. The key factor to check on would be that the diaphragm pump your thinking about can supply the quantity of material you would like (remember you'll typically want the pump to become running at approximately 50% capacity, for the most part, to lessen put on although the curve can have greater operating rates as options), within the distance you would like, and you've got the environment you have to run the pump.

How to find a Diaphragm pump

Ultimately a diaphragm pump is a terrific way to deliver the bulk of fabric rapidly and effectively. To get great outcomes out of your diaphragm pump, think about the four factors we discussed here to check out when selecting a diaphragm pump. By using this straightforward advice you'll be able to make sure you pick a diaphragm pump which will last and succeed. If you want further suggestions about diaphragm pumps to call us today.