How does ZZYP pressure regulator works

Working Principle of ZZYP Self Actuated Pressure Control Valve:

-400x400.webp)

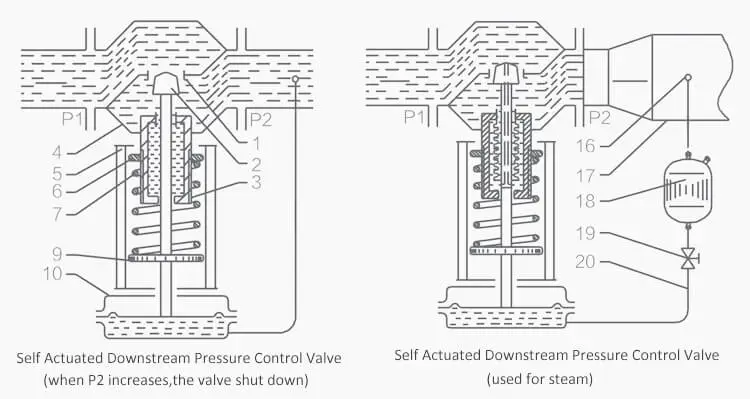

1.Self Actuated Pressure Downstream Control Valve:

The self actuated downstream pressure control valve is the valve that controls the pressure at downstream and the valve action type is press-to-close type. The principle is as follows:

The medium flows through the valve body in the direction of the arrow on the valve body. The interception area between the valve plug (No.2) and the valve seat (No. 1) determines the medium flow.The controlled downstream pressure (P2) is transmitted to the sensing element via the pressure guiding tube (No.20), the condenser (No.18) (used when the medium is steam) and globe valve (No.19), and is converted into a positioning force.The positioning force adjusts the position of the valve plug according to the spring force.The spring force is adjusted by the pressure regulating disc (No.6).The fully balance valve is provided with a balance bellows (No.8), and the downstream pressure P2 acts on the inner surface of the bellows, and the upstream pressure P1 acts on the outer surface of the bellows so that the pressures P1 and P2 acting on the plug are balanced with each other.

When the downstream pressure is greater than the adjusted set point,it compresses the spring and drives the plug, and then the valve opening is proportionally reduced according to the amount of pressure change. When the downstream pressure is lower than the set point, the valve plug is driven by the reaction force generated by the spring, so that the valve opening degree is proportionally increased according to the pressure change, thereby achieving the purpose of pressure reducing and stabilizing.

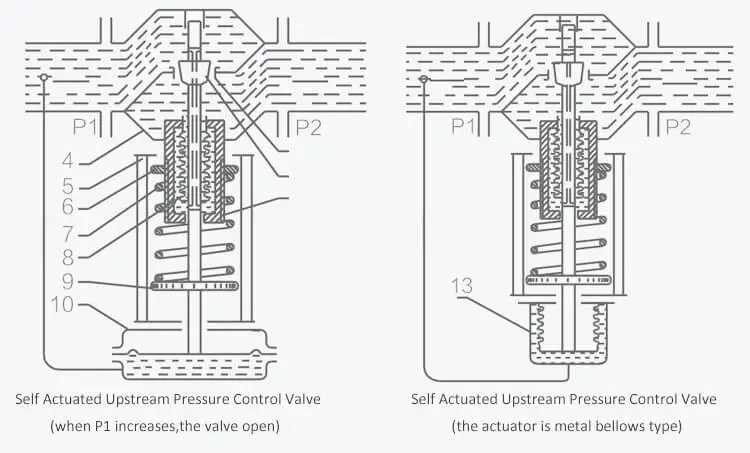

2.Self Actuated Pressure Upstream Control Valve:

The self actuated upstream pressure control valve is the valve that controls the pressure at upstream and the valve action type is press-to-open type. The principle is as follows:

The controlled upstream pressure (P1) is transmitted to the sensing element via the pressure guiding tube (No.20), the condenser (No.18) (used when the medium is steam) and globe valve (No.19), and is converted into a positioning force.The positioning force adjusts the position of the valve plug according to the spring force.The spring force is adjusted by the pressure regulating disc (No.6).The fully balance valve is provided with a balance bellows (No.8), and the downstream pressure P2 acts on the inner surface of the bellows, and the upstream pressure P1 acts on the outer surface of the bellows so that the pressures P1 and P2 acting on the plug are balanced with each other.

When the upstream pressure is greater than the adjusted set point,it compresses the spring and drives the plug, and the valve opens,then the valve opening increases proportionally with increasing pressure. When the upstream pressure reduces,the force acting on the detecting element is reduced. Under the reaction force of the spring, the valve plug is driven to reduce the valve opening, and the valve is closed when the pressure is lower than the pressure setting value, thereby achieving the purpose of pressure reducing and stabilizing.

Rated Kv and Travel & Pressure Regulating Range of Self Actuated Pressure Control Valve:

| DN(mm) | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| Rated Flow

Coefficient Kv |

Single-seat | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 | 300 | 480 | 760 | ||

| Cage | 7 | 11 | 20 | 30 | 48 | 75 | 120 | 190 | 300 | 480 | 760 | |||

| Double-seats | 22 | 33 | 53 | 83 | 132 | 209 | 330 | 528 | 836 | 1210 | 1925 | |||

| Rated Travel(mm) | 8 | 10 14 | 20 | 25 | 40 | 50 | 60 | 70 | ||||||

| Pressure Regulating

Range(kPa) |

15~50 40〜80 60~100 80~140 120~180 160~220 200~260 240~300 280~350

330〜400380〜450 430〜500 480〜560 540〜620 600〜700 680〜800 780-900 880-1000 950〜1100 1080~1250 1230〜1400 1380〜1550 1530〜1800 1780〜2000 1980〜2300 2280〜2500 |

|||||||||||||

The Application Features of Self Actuated Pressure Control Valve:

1. The pressure set point can be adjusted on the spot within the pressure regulating range;

2. The valve body part and the actuator are modularly designed, and the actuator or spring can be changed according to the requirements of the scene, so that the pressure regulating range can be quickly changed within a certain range;

3. The self actuated pressure single-seat control valve generally adopts a bellows as the pressure balance component.The pressure change of downstream and upstream does not affect the force of the valve plug,greatly speeding up the response speed of the valve, thereby improving the adjustment precision of the valve. If the small diameter, no bellows is required as the pressure balance element.

4.The self-operated pressure cage control valve adopts self-balancing double sealing surface cage as the throttle piece. The medium needs to be clean and without granular impurities.It is suitable for these occasions:large pressure drop,the valve diameter is not large (DN20~200),and no need to close.It is only used to control downstream pressure.

5.The self-actuated pressure double seats control valve adopts self-balancing double-sealed double-plug as the throttle piece, which is suitable for occasions with large valve diameter.

6. The choke structure is used to reduce the fluid flow rate and reduce the noise;

7. Piston type balance is used for these occasions:large pressure difference, the controlled medium is non-corrosive to rubber, and the temperature is not high.

8. The diaphragm type actuator uses a rubber diaphragm as the detecting element, which has the advantages of low resistance, quick response and high adjustment precision. It is suitable for pressure setting ≤0.6MPa.

9. The piston type actuator adopts the cylinder piston as the detecting component, and the rubber as the sealing member is suitable for the occasion where the control pressure is high, and is suitable for the pressure setting value ≥0.6MPa.

10. The bellows actuator adopts the bellows as the detecting component, which is suitable for the poor working occasions: high temperature (the working medium can not be used with the spacer liquid), low temperature,the controlled medium is corrosive to rubber parts, etc.

11. When the medium is steam, if use membrane type or piston type actuator, a condenser tank is required to reduce the temperature of the working medium in the actuator and protect the diaphragm or sealing parts.