GOOD REPUTATION FOR SPLIT-CASE PUMPS

A split-situation pump, correctly installed, designed, and operated, can offer decades and services information.

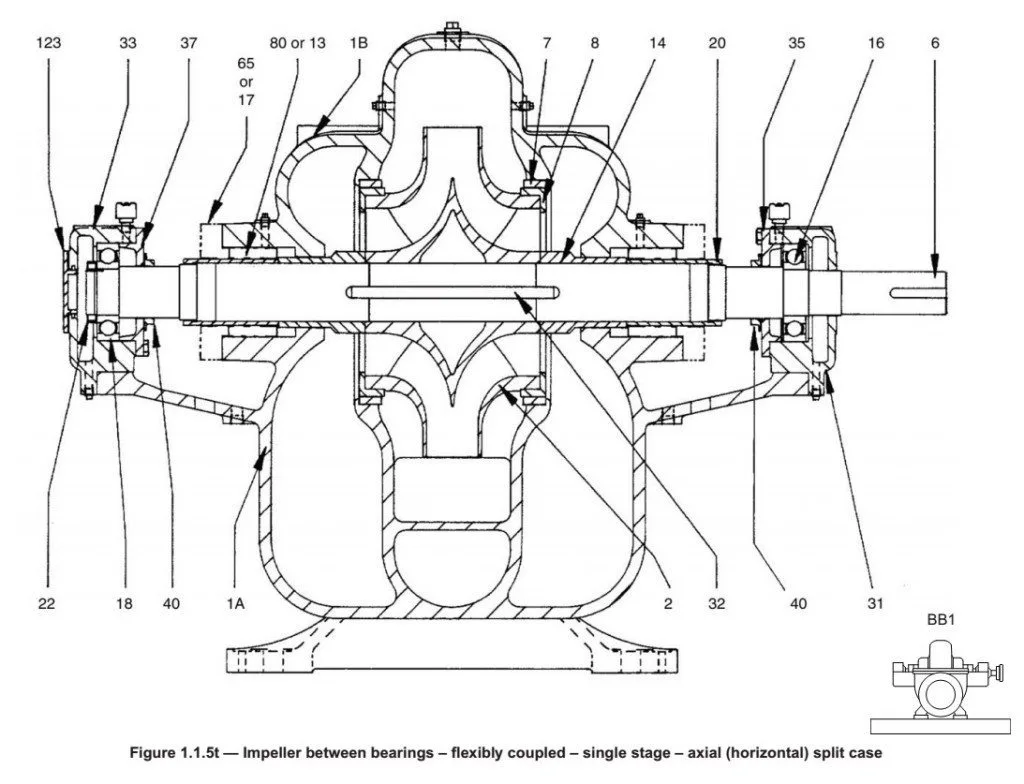

Axially-Split Horizontally-Mounted Pump

Most split-case pumps are axially-split - and therefore the flange where the pump casing separates is incorporated in the same plane because of the pump axis. Radially-split pumps can also be found, and therefore are generally utilized in high-pressure and-temperature industrial applications (boiler-feed pumps is one common application for radially-split pumps).

The diagram and pictures proven in this article are suitable for the greater run-of-the-mill axially-split variety which is used extensively in municipal water, industrial, oil & gas, and mining applications.

While split-situation pumps are usually mounted horizontally, as proven during these images, it's not uncommon for split-situation pumps to become mounted vertically, along with a couple of manufacturers offer specialized bases and casings created for this arrangement. However, most manufacturers simply adopt a typical horizontal the perception of vertical mounting - an exercise that isn't without safety concerns and, consequently, a good share of detractors.

A Well-balanced Design

What exactly makes split-situation pumps the dependable workhorses that there? Everything comes lower to create.

Between-the-bearings: Split-situation pumps are what is called a “between-the-bearings” pump. Which means that split-situation pumps mount the impeller on the shaft that's based on bearings on sides from the impeller.

Double-suction impeller: Split-situation pumps would be the only COMMON pump type having a double suction impeller. A dual-suction impeller imposes dramatically fewer loads around the bearings than an impeller that just allures water in one side from the impeller (single-suction).

Split-situation pumps are, by design, a far more-balanced machine than almost every other type of pumps. Along with robust bearings along with a maintenance-friendly casing design, split-situation pumps would be the design-of-option for many municipalities and production facilities.