EXACTLY WHAT IS A MAGDRIVE PUMP SO WHEN / WHY WOULD I WANT ONE?

The bond between your motor drive and also the pump drive is created using a magnetic connection which fits with the isolation shroud. Which means that there's no direct or indirect path by which any fluids or gases can escape which could pose a danger to both operators and also the atmosphere.

Mag-drive pumps come in a number of materials of construction including surefire/ductile iron, 316 stainless, and Hastelloy. This kind of pump plays a role in the technical standardization in process engineering because of its universal applications.

Mag-drive pumps can be found in close-coupled and lengthy-coupled (frame mounted) configurations.

When / why would I want one?:

Generally once the product being pumped is of the corrosive nature, or even the leakage of this product can harm operators or damage the atmosphere.

Types of such products could be:

Muriatic Acidity

Methane

Sodium Sulphate

Sodium Hydroxide

Sodium Hypochlorite

Sulphuric Acidity

What can be some typical applications individuals goods are utilized in?:

Tanker Unloading

Batch Chemical Processes

Specialty Chemicals

Column Reflux

Reactor Feed

So how exactly does it vary from, for instance, just one / double robotically-sealed pump?:

Most pump types, aside from magnetic drive pumps, possess a shaft which goes through the pump casing. The shaft is encircled with a seal which can leak. This leakage could be minimized first of all through seal quality, and next through a seal-fluid pressurization system ¨C generally known as “seal pots”. The adjacent image shows a disc pack Discflo lengthy-coupled pumping system, fitted having a seal-fluid pressurization system.

The seal-fluid pressure is greater compared to suction pressure within the pump. It prevents, or at best minimizes the opportunity of, the merchandise getting away beyond the seal.

For applications where the potential for the tiniest volume of product getting away might be hazardous, however, the mag-drive pump is really a solution as there's no shaft seal for that the merchandise to flee past.

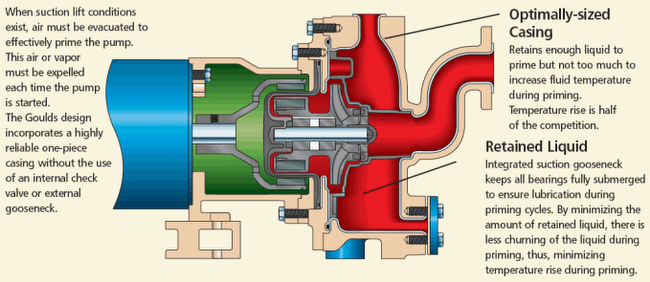

This is often seen clearly within the graphic below, in which the product being pumped (proven in red) doesn't have a connection directly or not directed towards the pump shaft:

Illustration of lengthy-coupled (frame-mounted) pump-set with the seal-fluid pressurization system

Benefits:

Reduced customer Existence Cycle Cost (LCC) by minimizing maintenance, operating & installation cost

An extensive selection of materials and accessories can be found to satisfy customer needs

Integrated options for connecting safety & monitoring devices, e.g. Goulds PumpSmart®

Design standardization & simplification to maintain easy maintenance & to reduce spares inventory needs

Drive magnet set up rich in-performance permanent magnets

Design Features:

Close-coupled Design

Arrangement eliminates have to perform pump/motor alignment. Single piece, dual-secure circle adapter accommodates needed motor sizes for optimum application versatility.

Lengthy-coupled (frame-mounted) Design

For easy dis-set up for preventative maintenance, overhaul or general periodic inspection.

One-piece Enclosed Impeller

Minimizes axial thrust for a longer thrust bearing existence. Unlike two-piece designs, one-piece construction eliminates the chance of front shroud failure.

Solid Stationary Shaft

The fully supported stationary design maximizes radial bearing existence and reduces shaft deflection. Straight geometry eliminates stress concentrations and chance of failure during pump operation

Rare-earth Magnets

High strength neodymium iron, provide high torque and difficult-start capacity without slip. A drive is synchronous.

mag-drive pumps

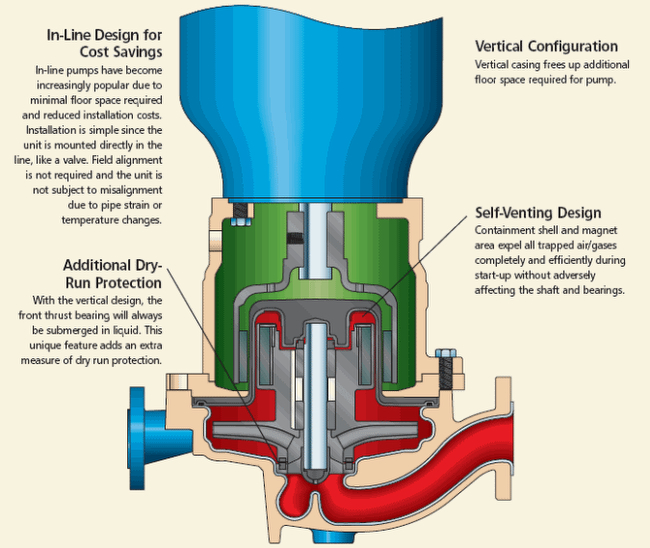

In-line configuration:

An alternative choice provided with a mag-drive pump is definitely an in-line version, in which the pump is installed vertically. In-line mag-drive pumps are usually close-coupled, although a lengthy-coupled configuration can be done. The in-line configuration could be helpful where space is confined because the pump is installed directly within the line, as being a valve:

There's more information on our website concerning the technical options that come with magnetic-drive pumps.