Difference Between V-port Ball Control Valves and Globe Control Valves

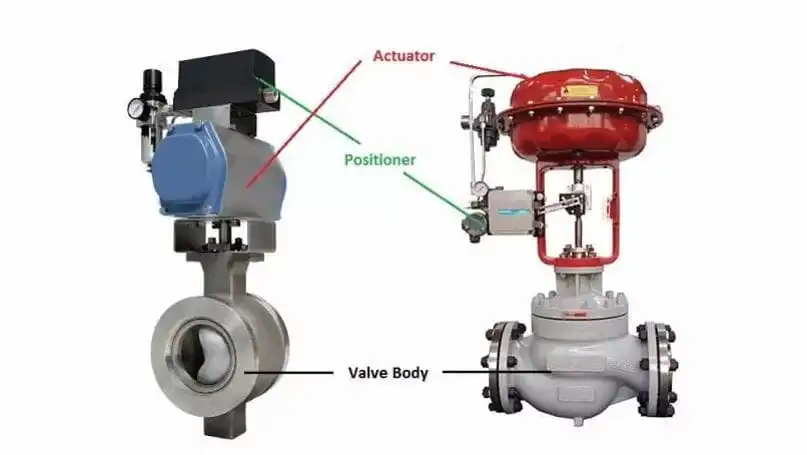

Figure 1: V-Port Ball Valve (rotary) vs. Globe Contro Valve (linear).

Both v-port ball valve and globe control valve include of three main parts: valve body, actuator, and positioner. as shown in figure 1 to see each part.

When we selecting a particular condition of control valves, usually we will consider V-port ball valves and globe-type control valves. The following are the points to differentiate them.

1. Action type

V-port ball valves use rotary motion so the installation space is more compact than globe-type control valves, which use linear motion.

2. Flow coefficient Cv

Compared to the globe control valve of the same size, the v-port ball valve has higher flow coefficients Cv.

It means that a smaller V-ball control valve can be used to achieve the same flow rate as a comparable globe control valve. But due to the flow curve of the v-port ball valve is not ideal, it’s not an uneven increase of flow when compared to the degree of rotary. So for high precise flow control, we still prefer to use globe-type control valves.

3. Budget

According to point 1. 2, we know that v-port ball valves are lower budget than globe control valve, with small size and compact installation space. Typically, a V-Port Ball Valve will be 35% to 50% less than a Globe Valve.

4. Shutoff Tightness

The v-port ball valve uses a floating ball to close the valve with a rotary motion, which provides a tight shut-off with zero leakage and regulates flow function. When the valve is closed, upstream pressure pushes the ball against the downstream seat, thus enhancing the seal. But for globe-type control valves, it’s hard to achieve zero leakage, which usually complies with ANSI FCI 70-2 Class II, III, IV, V, VI.

5. Closure Component Design

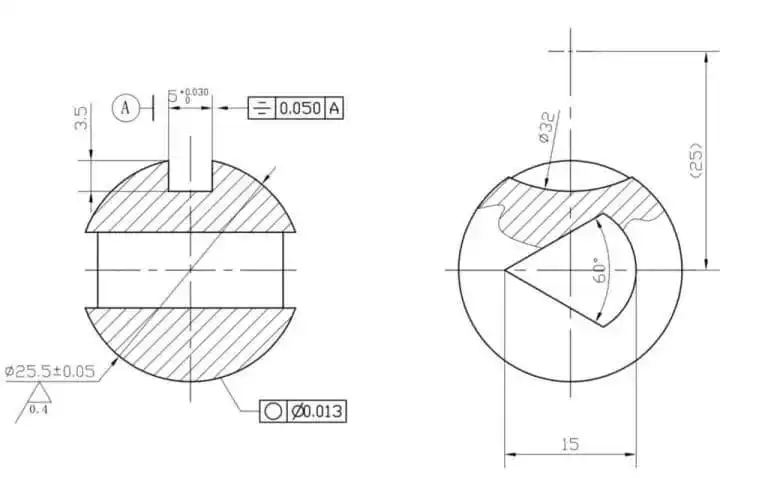

60-degree ball valve

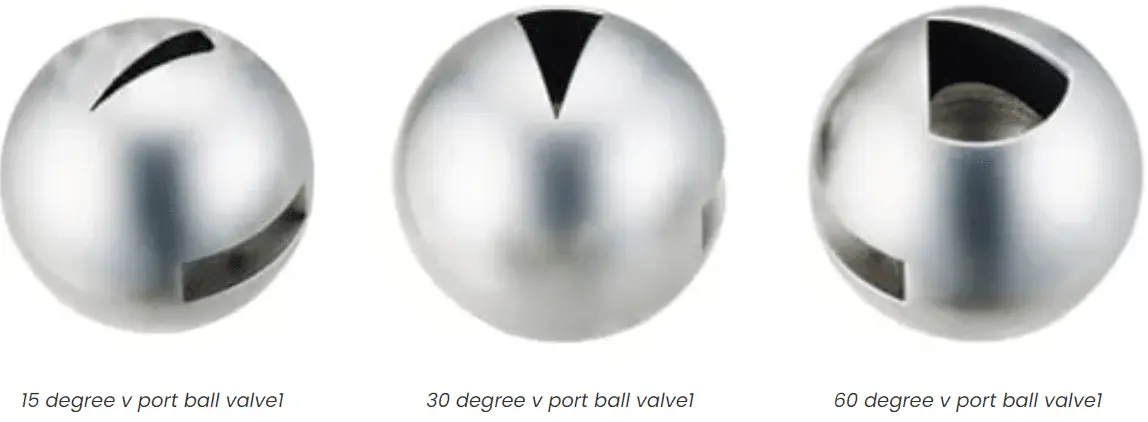

V-port ball valves are specialized ball valves with different V segment options in the ball part, 30°, 60°, and 90°. The 30° segment makes a better-tapered control throughout the valve rotary, and 60° and 90° offers a larger Cv than 30°.

Globe Control Valves vs. V-Port Ball Valves

| Item | Globe Type Control Valve | V-Port Ball Valve |

| Function | 2-Way Flow Control Valve 3-Way Mixing Type Control Valve 3-Way Diverting Type Control Valve |

2-Way Flow Control Valve |

| Shutoff Tightness | Not Zero Leakage | Positive Shutoff, Zero Leakage |

| Control Accuracy | Excellence | Coarse |

| High Response Cycle | Yes, Constant Control | No |

| Flow Capacity | Lower | Higher |

| Cavitation Prevention | Priority Selection | – |

| High Temperature | Priority Selection | – |

| Easy Maintenance | Priority Selection | – |

| Cost | – | More Economical Solution |

Previous: What is Blind Flanges