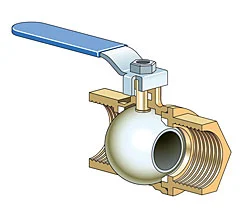

CAN A BALL VALVE BE UTILIZED FOR A CONTROL VALVE?

Despite the fact that ball valves are not the very best device to manage flow, they're still generally used due to their afford-ability. You will get away with utilizing a ball valve within an application that does not require precise adjust-ability and control. For instance, a ball valve shouldn't have any problem keeping a sizable tank filled in a certain level inside a couple of inches.

Just like any equipment, you will have to go ahead and take complete process conditions into account prior to you buying your valve. Including the merchandise or material, size piping, flow rate, etc. If you're attempting to control an costly material that you're concerned about wasting, you will possibly not wish to depend on the ball valve.

Ball valves are not very precise as their adjustment is not proportionate towards the great deal of flow the open hole provides. There's also "stop" or "play" among the stem and ball that hinders precise control. Lastly, the quantity of torque needed to regulate ball valves does not permit fine adjustment close to the "closed" and "open" position.

When you really need precise control of the application, a globe valve could be more accurate than the usual ball valve. Globe valves are seen as the industry standard for control valves since they're proficient at controlling flow, whereas ball valves be more effective for on/off control without pressure drop.

V-Port Ball ValveIf you have to make use of a ball valve to manage your process, you might like to consider various kinds of ball valves based on the application. A trunnion or v-port ball valve will work better and permit for additional accurate adjust-ability in a few scenarios.

Trunnion ball valves come with an additional mechanical anchoring from the ball at the very top and bottom. They will use a splined or keyed stem connection that eliminates any play between your ball and stem. V-port ball valves possess a "V" formed ball rather from the standard round hole. This enables for additional control due to the tapered opening, permitting more straight line flow.

If you are situated in Wisconsin or Upper Michigan and want help deciding which valve is most effective for the application, achieve to our engineers. Otherwise should you enjoyed reading this article, you might like to take a look at our publish about when you should use soft-seat ball valves versus. metal-seat ball valves.