Ball Valve vs. Butterfly Valve | Detail Comparison - SHINJO

The choice of the correct valve of your application is an important task when designing a process system. As a general rule, the properties and characteristics of each type of valve make it right for deciding that best suits a particular function. However, for specific applications, several types of different valves can work. Therefore, it is essential to know which type of valve will suit your specific application.

Butterfly valves and ball valves offer unique advantages, then choose between them in some processes, it is not a difficult choice. It can be problematic when a process requires valve characteristics that both valves have. We need a deeper understanding of the butterfly valve and ball valve to choose the correct valve.

In terms of operation mechanisms, both valves are probably the simplest of the types of available valves. They are widely used in domestic, commercial and industrial applications for controlling fluid fluids in a wide range of temperatures and pressures. These are rotating valves quarter-turn (90 ° turn completely closed to completely open). The two types of valves can be controlled manually, with an electric actuator or with a pneumatic actuator. Butterfly valves are relatively inexpensive, easy to maintain, reliable and have long life expectancy than other types of valves.

These similarities do not mean that the valves are interchangeable in all process functions. Instead, this suggests and corroborates why we need to look more closely about the characteristics of the valve and which applications use each valve.

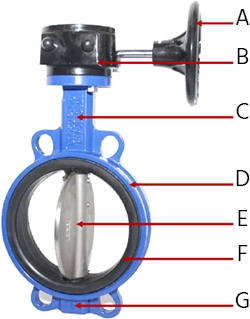

Understanding the butterfly valve

A butterfly valve has a disc (E) driven by a lever or handwheel (A). When closed, the disc is perpendicular to the pipe flow direction. A seal (F) which seats within the valve body (D) ensures a tight closure with the valve disc. A butterfly valve's valve characteristics are close to a linear relationship between the flow rate and the stem (C) position. The butterfly valve can be controlled manually, electrically, or pneumatically.

- In larger diameters, butterfly valves are generally considered cheaper than ticket valves. They have the slightest amount of parts and are relatively light, requiring less support. The weight advantage of the butterfly valves of the ticket valves can be significant at diameters of larger pipes. There is a higher probability of leaks at high pressure differences between the sides of a throttle valve disc and the seal with a ball valve. In addition, in applications with large pipe diameters, this high-pressure difference makes it difficult to open the valve, thus requiring a bypass valve to balance the pressure of both until the valve can be opened.

- There is a pressure drop on the butterfly valve when the disc remains inside the flow even when it is completely open. This hinders with butterfly valves in process flows that must be checked, as in the oil and gas industry. Butterfly valves are usually valves / off and are not suitable for precise fluid flow control.

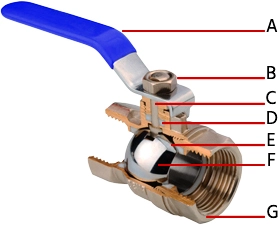

Understanding the ball valve

A ball valve has a hollow spherical ball (F) that is pivoted at one or both ends. The top end of the ball is attached to a shaft (C), which is rotated by a handle (A) to change the valve position to open or close. When fully open, the hole in the ball lies parallel with the pipe flow direction. The ball rests on a seat (E) inside the valve body (G). The ball valve can be controlled manually, electrically, and pneumatically.

- The ball valves may also have three-way or four-lane flow directions in a "T" or "L" bore. The flow characteristics of a ball valve can be read in our technical article on the control of fluid flow with ticket valves.

- The bore in a ball valve may vary from a size lower than the diameter of the pipe (reduced port or reduced bore), a size equal to the diameter of the pipe (integral port), or a port V design. The design of the ball. affects the flow characteristics. A ball valve can have a pressure drop on the valve in a reduced port faster valve or pressure drop almost zero in a complete port ticket valve, while a port V design is ideal for a command Stable flow.

- Unlike butterfly valves, the ball valves have a leak of zero when they are completely closed. The fluid pressure upstream of the valve pushes the ball against the seal, ensuring a positive stop position. The ball valves open easily to a high-pressure difference on both sides of the valve and therefore do not require a pressure balancing derivation.

The following criteria can be considered before selecting between a butterfly valve and a ball valve:

- Application: Butterfly valves are commonly used in water-based processes such as sewages, beer and soda production, etc. They are popular in chemical, agricultural, waste treatment plants, and food industries, partly because they are easy to clean. Ball valves can handle both liquid and gases with some solid particles (slurry). They are common in process plants, power plants, petroleum refining, oil, and gas exploration as they can be 'pigged' for cleaning.

- Flow capacity: Butterfly valves can provide a larger flow capacity as they are readily available at a larger pipe diameter than a ball valve.

- Sealing: Ball valves provide a tight seal in process applications that require zero leakages when shut off.

- Operating condition: Ball valves can operate up to 1,000 bar and 400 degrees Celsius. Butterfly valves typically operate at a lower pressure (less than 50 bar) and temperature (less than 250 degrees Celsius).

- Flow regulation: Both valve types can be used for on/off control and proportional control, but ball valves are typically used for proportional due to better flow regulation.

- Ports: A butterfly valve can only have two ports, while a ball valve can have more than two ports.