API6D Valve types

6.1.1 Gate valves

Typical configurations for gate valves with flanged and welding ends are shown, for illustration purposes only, in Figures 1 and 2. Gate valves shall have an obturator that moves in a plane perpendicular to the direction of flow. The gate can be constructed of one piece for slab-gate valves or of two or more pieces for expanding-gate valves. Gate valves shall be provided with a back seat or secondary stem sealing feature in addition to the primary stem seal.

Figure 2 - Siab-gate/through-conduit rising-stem gate valve

6.1.2 Lubricated and non-lubricated plug valves

Typical configurations for plug valves with flanged and welding ends are shown, for illustration purposes only, in Figure 3. Plug valves shall have a cylindrical or conical obturator that rotates about an axis perpendicular to the direction of flow.

6.1.3 Ball valves

Typical configurations for ball valves with flanged or welding ends are shown, for illustration purposes only, in Figures 4, 5 and 6. Ball valves shall have a spherical obturator that rotates on an axis perpendicular to the direction of flow.

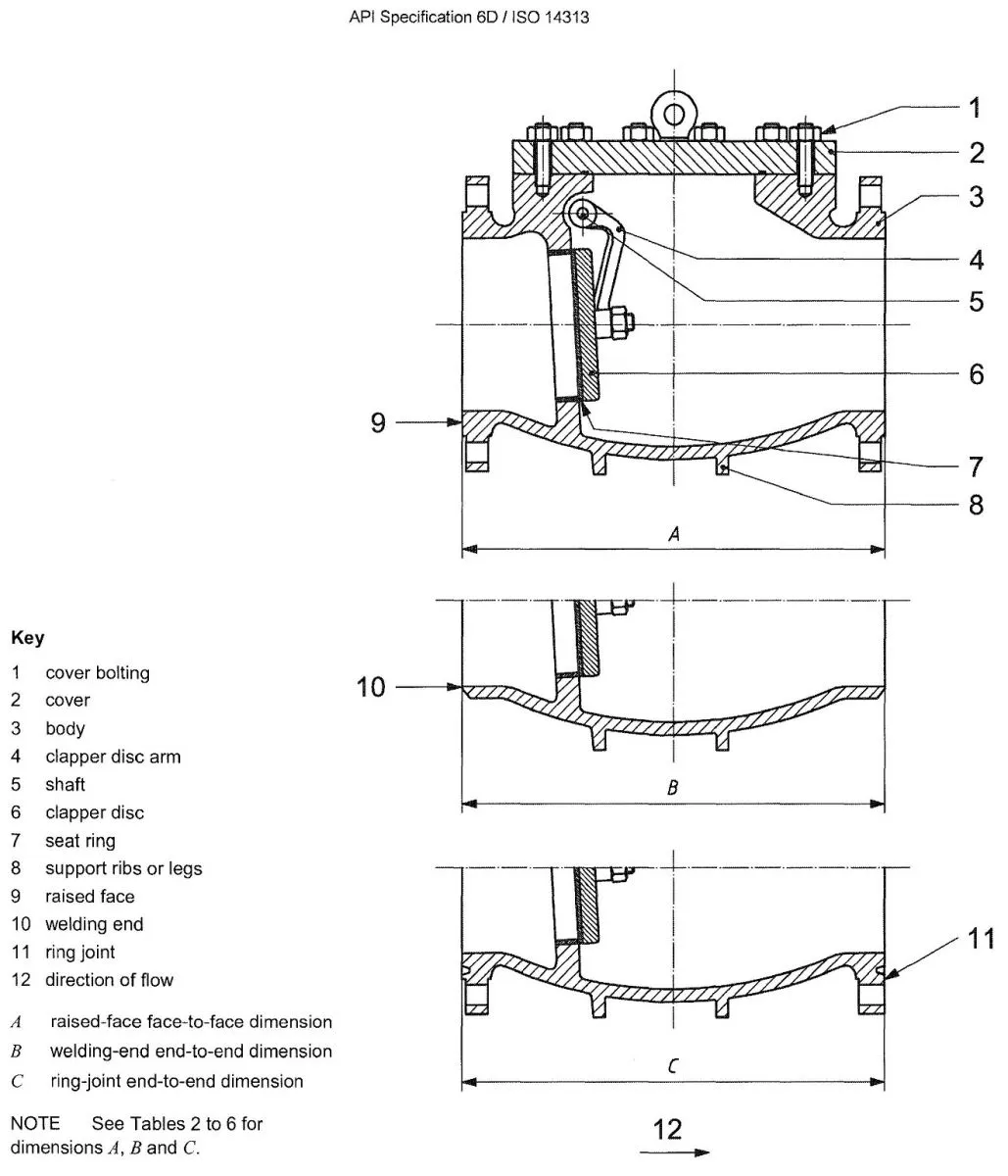

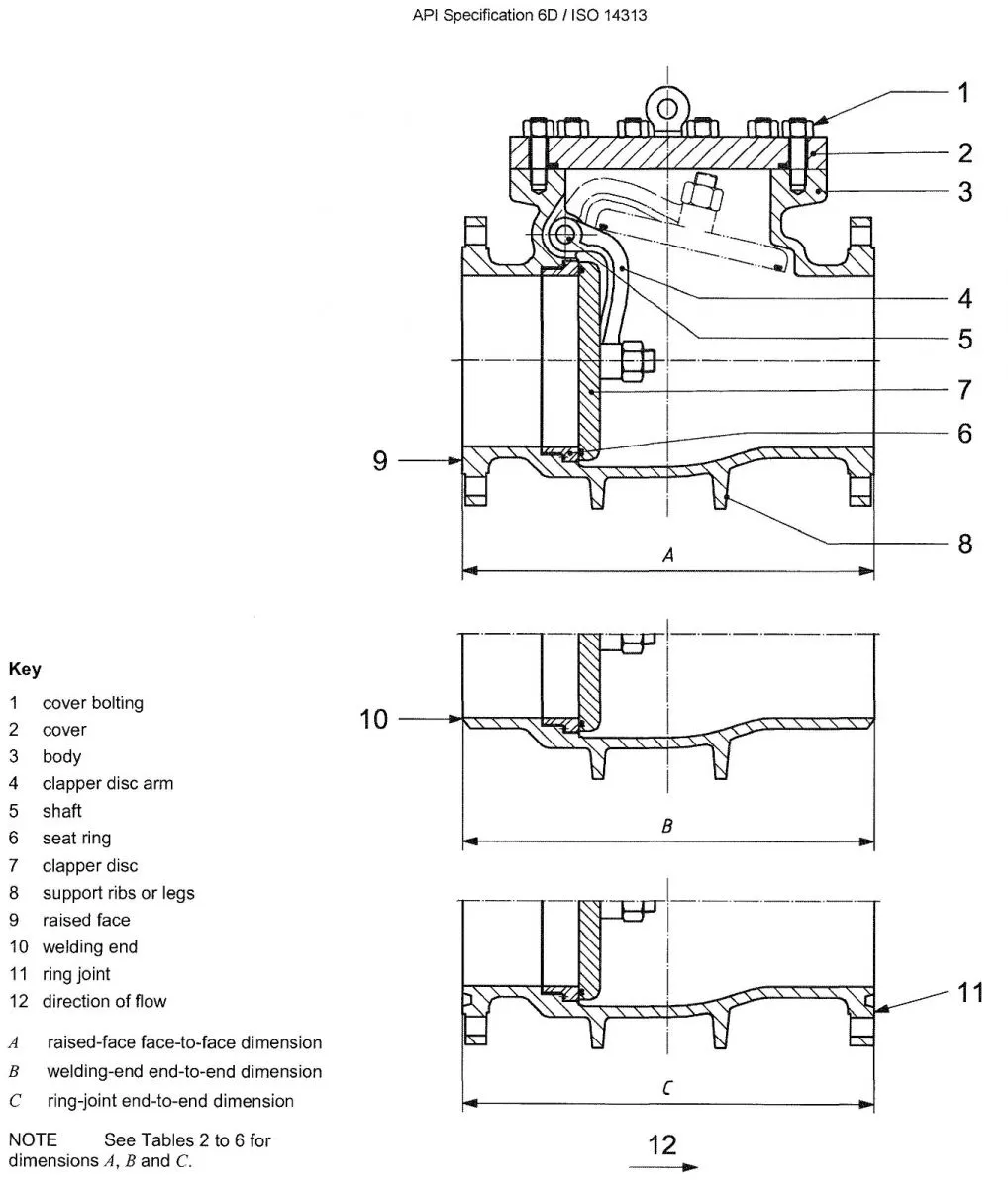

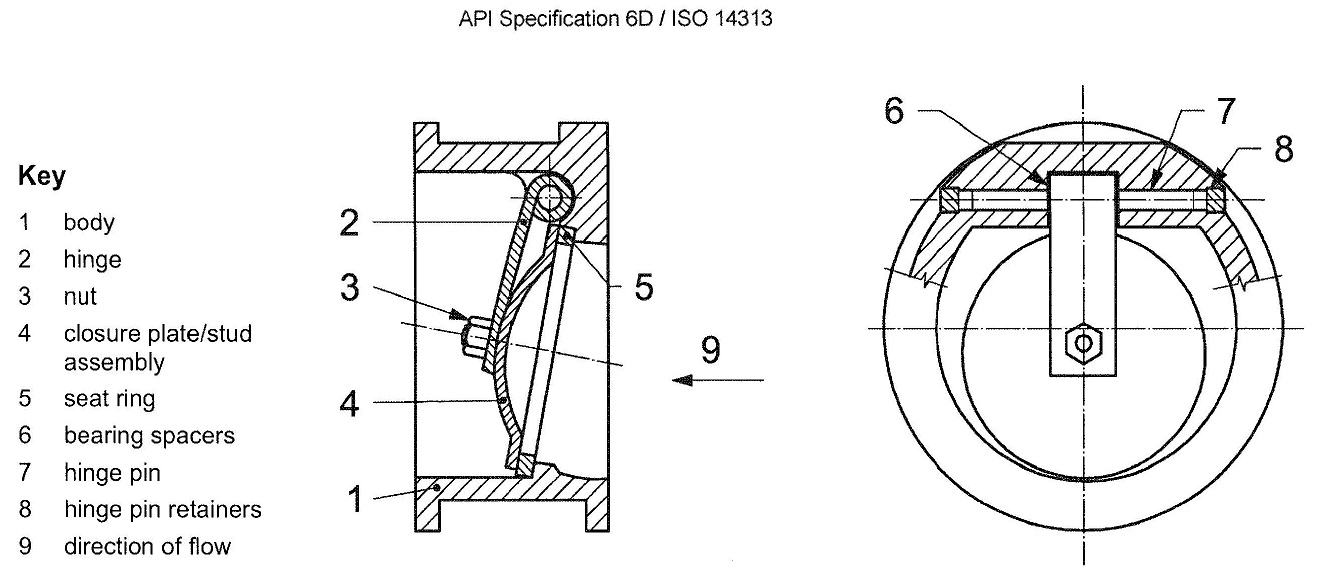

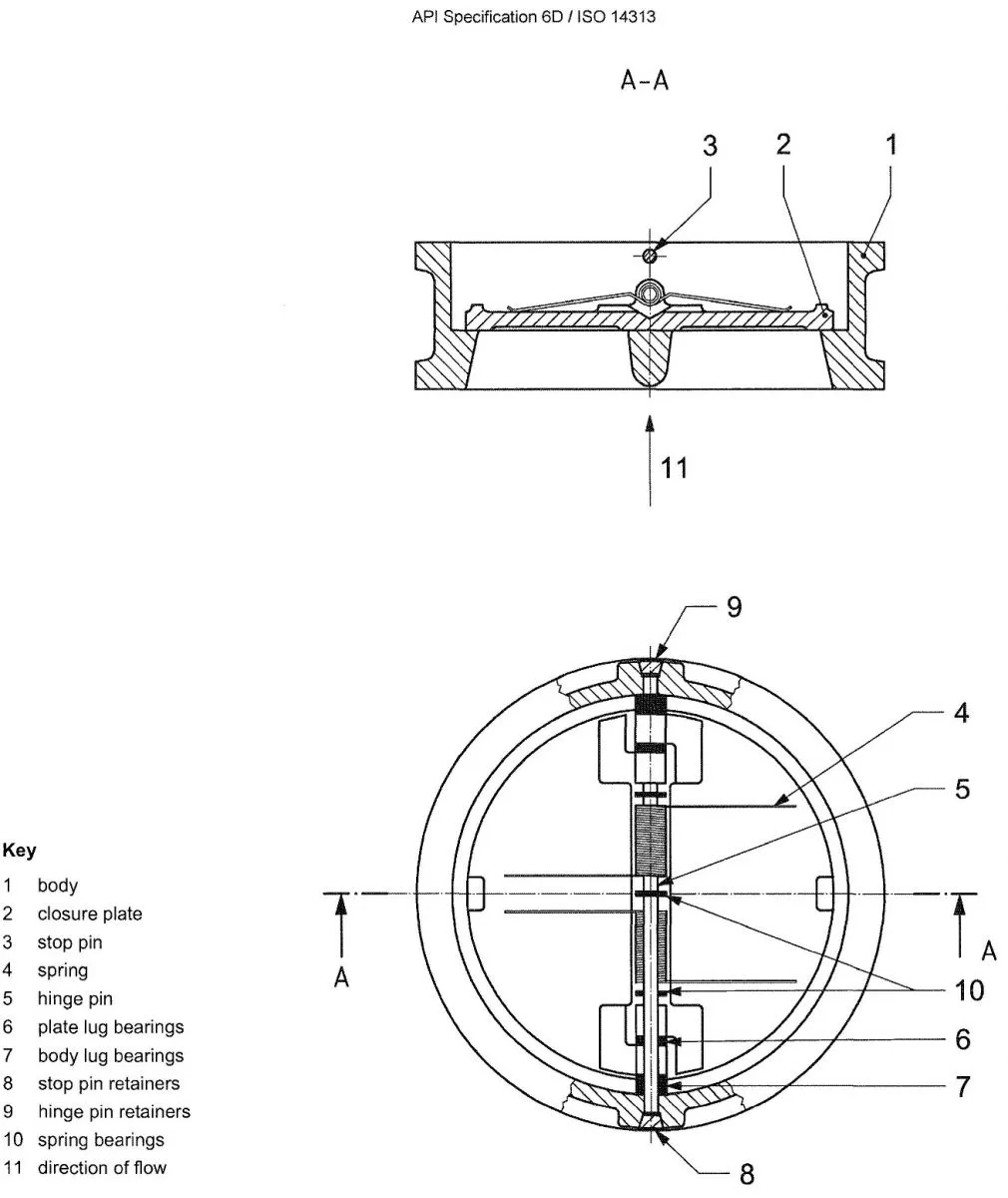

6.1.4 Check valves

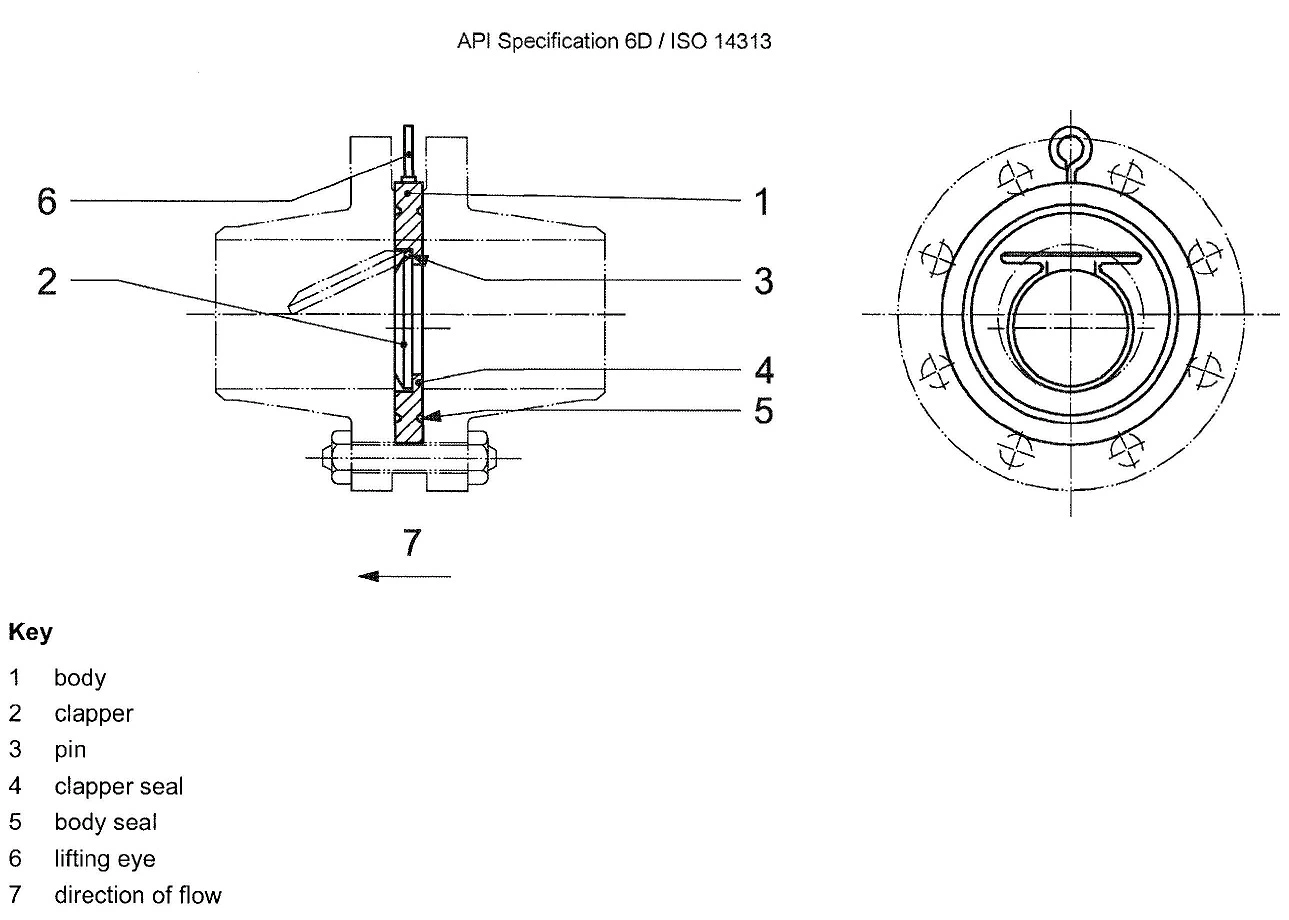

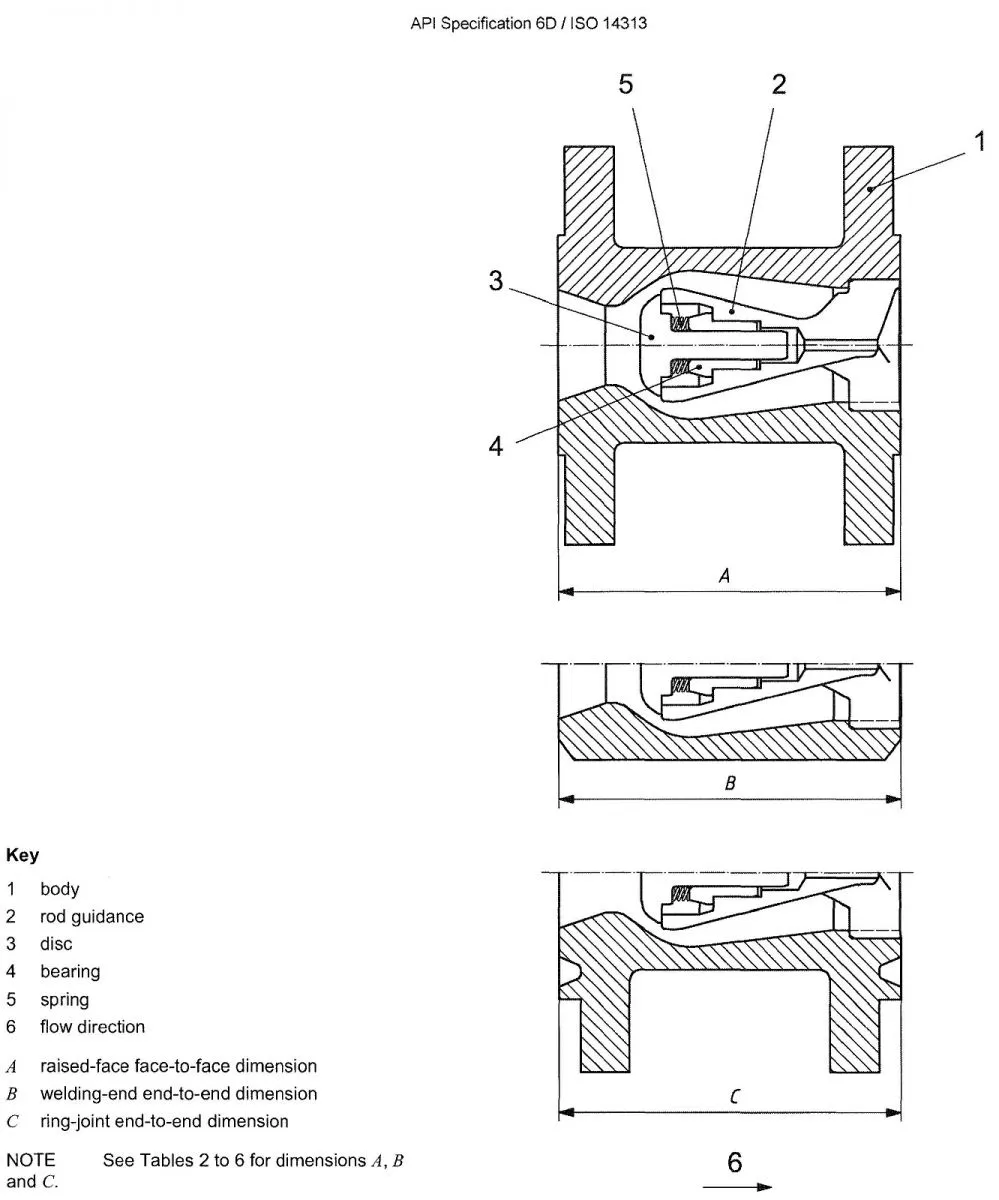

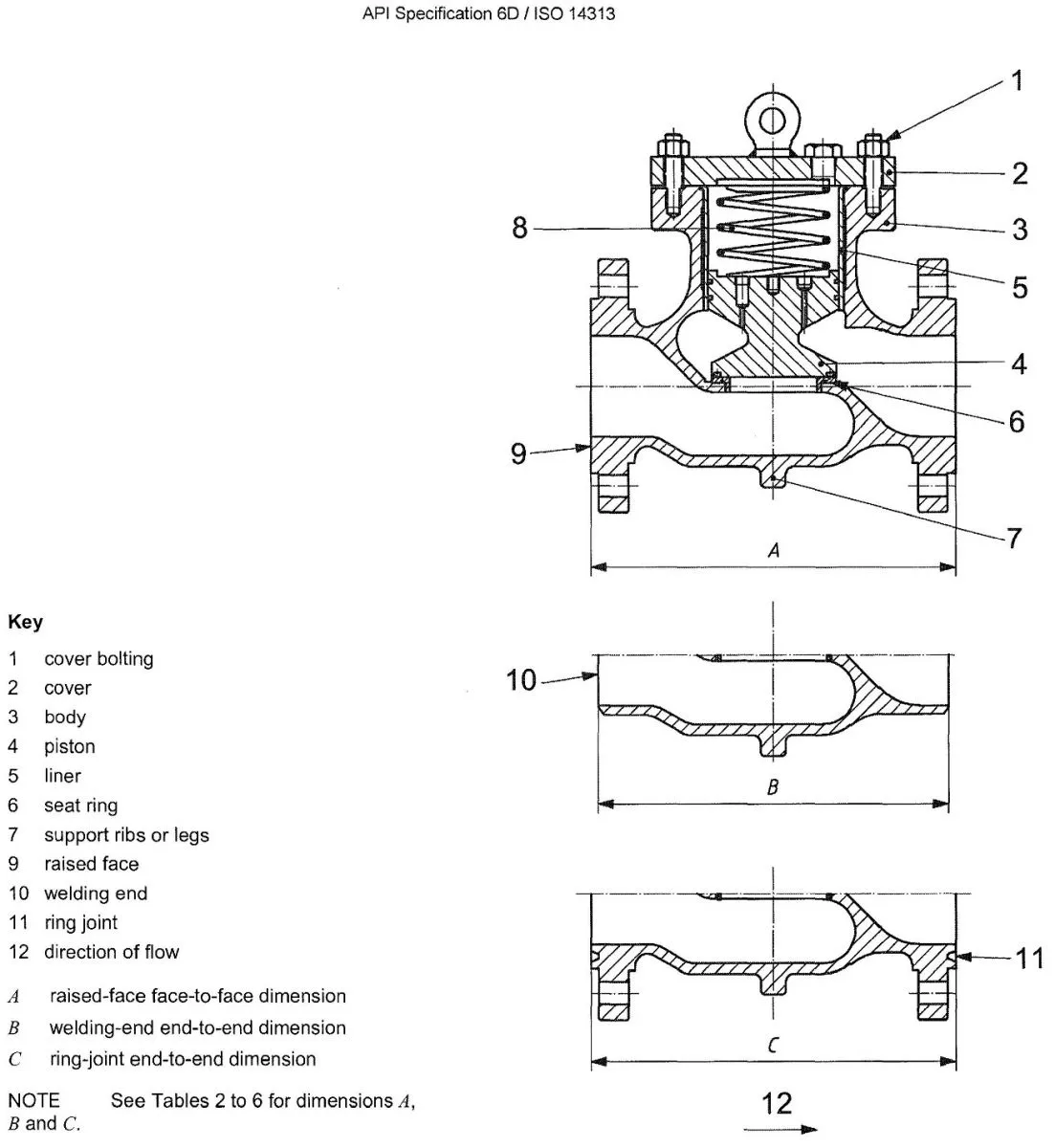

Typical configurations for check valves are shown, for illustration purposes only, in Figures 7 to 13. Check valves can also be of the wafer, axial flow and lift type. Check valves shall have an obturator which responds automatically to block fluid in one direction.

Figure 7 - Reduced-opening swing check valve

Figure 8 - Full-opening swing check valve

Figure 9 - Single-plate wafer-type check valve, long pattern

Figure 10 - Typical dual-plate wafer-type check valve, long pattern

Figure 11 - Single-plate wafer-type check valve, short pattern

Figure 12 - Axial flow check valve

Figure 13 - Piston check valve