Key Specifications / Features

Model No.: SJ-MP-13 Hits: 131

Detail Information

JYSZ series hydraulic diaphragm pumps are an integrated pump that can offer precise dosing performance minimal maintenance. It is integrated safety valve against overload pressure. The PTFE diaphragm is durable and provides consistently accurate metering.

Features of SHINJO Hydraulic Diaphragm Metering Pump:

Shinjo hydraulic diaphragm metering pump consists of three main devices: (1) driving device, (2) adjusting device, (3) liquid delivery device. The crankshaft which reduces motor rotation speed by worm and worm gear makes the piston reciprocate in the hydraulic oil chamber. This reciprocating movement of the piston makes the PTFE diaphragm and the liquid which is isolated by the diaphragm sucked and discharged. Each pump is with internal pressure relief valve protecting the pump from overpressure conditions.

The flow rate can be adjusted via unique adjusting mechanism from 0-100%. The adjustment can be carried when the pump is in operation or at stop. The steady state accuracy is ±1% from 30%-100% of the maximum output. Automatic operation is achieved by variable speed drive.

SHINJO hydraulic diaphragm metering pumps are capable of dosing corrosive, vaporing, flammable, explosive or toxic solutions. It can also transport suspended liquid or moderately viscous liquid.

Double diaphragm with diaphragm rupture detecting system is available to prevent the accident caused by the mixture of hydraulic oil and the liquid after diaphragm ruptures.

Materials:

1. Pump head: SS304, SS316

2. Pump case: Cast iron

3. Diaphragm: PTFE

4. Valve: SS304, SS316

5. Valve ball: SS304, SS316, ceramic

Power Supply:

380V 3 phase on standard, single phase or other voltage on request; EX-proof motor is available on request.

Parameter Table:

| Model | 50Hz | 60 Hz | Pressure | Plunger Dia. (mm) |

Diaphragm Dia. (mm) |

Stroke Length (mm) |

Power kW(HP) |

Inlet&Outlet Size | Connection Size | |||||

| Flow (lph) |

Flow (gph) |

SPM | Flow (gph) |

Flow (lph) |

SPM | (Bar) | (Psi) | |||||||

| JYSZ10/20 | 10 |

2.6 | 96 | 3.2 | 12 | 115.2 | 200 | 2900 | 12 | 80 | 25 | 0.75(1) | DN6 | DN15 (union for welding) |

| JYSZ15/20 | 15 | 4.0 | 144 | 4.8 | 18 | 173 | 200 | 2900 | 12 | 80 | ||||

| JYSZ35/10 | 35 | 9.2 | 11 | 42 | 100 | 1450 | 16 | 92 | ||||||

| JYSZ45/9.0 | 45 | 12 | 14 | 54 | 90 | 1305 | 18 | 92 | ||||||

| JYSZ60/7.2 | 58 | 15 | 18 | 69.6 | 72 | 1044 | 20 | 92 | DN10 | DN15 (union for welding) |

||||

| JYSZ70/6.0 | 72 | 19 | 23 | 86.4 | 60 | 870 | 22 | 110 | ||||||

| JYSZ100/4.0 | 100 | 26 | 32 | 120 | 40 | 580 | 25 | 110 | ||||||

| JYSZ130/3.2 | 135 | 36 | 43 | 162 | 32 | 464 | 30 | 110 | ||||||

| JYSZ150/2.8 | 150 | 40 | 48 | 180 | 28 | 406 | 32 | 130 | DN15 | DN15 (union for welding) |

||||

| JYSZ200/2.2 | 200 | 53 | 63 | 240 | 22 | 319 | 36 | 130 | ||||||

| JYSZ240/1.8 | 240 | 63 | 76 | 288 | 18 | 261 | 40 | 130 | ||||||

| JYSZ300/1.4 | 300 | 79 | 95 | 360 | 14 | 203 | 45 | 130 | ||||||

| JYSZ400/1.1 | 400 | 106 | 127 | 480 | 10 | 145 | 50 | 130 | DN15 | DN15 RF | ||||

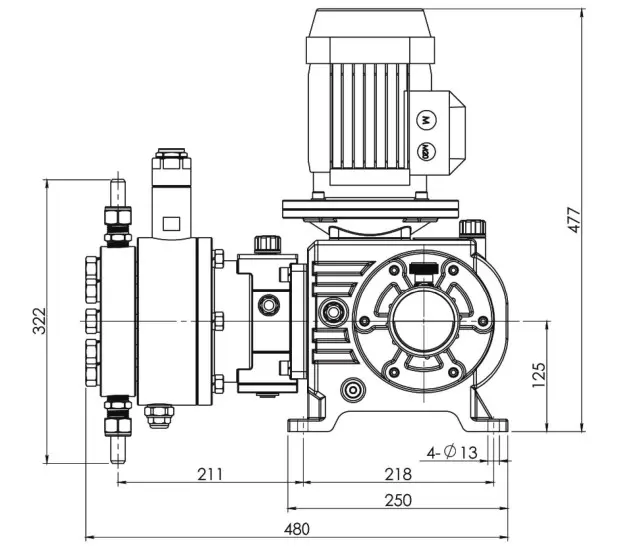

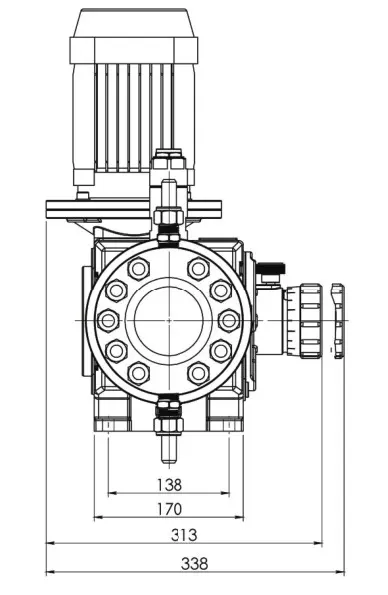

Installation Drawing: