Key Specifications / Features

Model No.: SJ-HV-04 Hits: 174

Detail Information

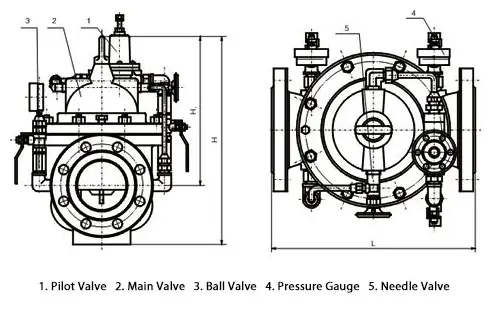

The 200X, Pressure Reducing Control Valve consists of Basic valve pressure reducing pilot. It automatically reduces a higher inlet pressure regardless of changing flow rate or varying inlet pressure. The pilot valve responds to slight fluctuation in the downstream and thus governs the control pressure.

200X Pressure Reducing Control Valves utilizes the self-energy of the medium to adjust the pipeline pressure and control the outlet pressure of the main valve through adjusting the pressure reducing of pilot valve.

The outlet pressure does not change along with the variation of the inlet one and the water quantity of the outlet. It features by reliable performance, easy installation, maintenance, debugging and check, long duration.

DN 450 Diaphragm type valve

DN 500 piston type valve

Materials

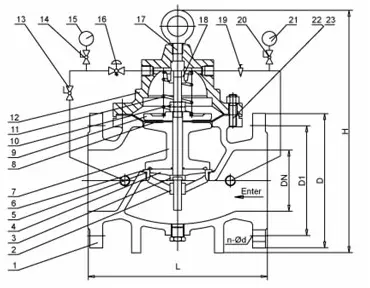

| Serial No. | Part | Material |

| 1 | Body | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 2 | Seat | 410 S.S. / SS 304 / SS 316 |

| 3 | Stem | 410 S.S. / SS 304 / SS 316 |

| 4 | O-ring washer | Cast Iron |

| 5 | O-ring | NBR |

| 6 | O-ring | NBR |

| 7 | Disc | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 8 | Diaphragm | Rubber |

| 9 | Diaphragm Washer | Cast Iron |

| 10 | Screw | Bronze |

| 11 | Spring | Spring steel |

| 12 | Cover | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 13 | Ball Valve | Bronze |

| 14 | Ball valve | Bronze |

| 15 | Pressure show | |

| 16 | Pilot valve | Bronze |

| 17 | Hang ring | Steel |

| 18 | Pilot socket | Bronze |

| 19 | Needle valve | Bronze |

| 20 | Ball valve | Bronze |

| 21 | Pressure show | |

| 22 | Stud | Steel |

| 23 | Screw | Steel |

Dimensions

| DNmm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | |

| L | 180 | 180 | 180 | 203 | 203 | 235 | 285 | 360 | 400 | 455 | 585 | 650 | 800 | 860 | 915 | 980 | 1075 | 1230 | 1300 | 1450 | |

| PN10 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 390 | 440 | 500 | 565 | 615 | 670 | 780 | 895 | 1010 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | |

| PN16 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 460 | 520 | 580 | 640 | 705 | 840 | 910 | 1020 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | |

| PN25 | D | 105 | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 | 955 | 1070 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | 875 | 990 | |

| H | 342 | 342 | 342 | 395 | 395 | 405 | 430 | 510 | 560 | 585 | 675 | 730 | 760 | 840 | 910 | 1030 | 1135 | 1270 | 1460 | 1640 | |

| H1 | 247 | 247 | 247 | 278 | 278 | 298 | 313 | 350 | 365 | 420 | 450 | 470 | 490 | 526 | 570 | 610 | 665 | 725 | 865 | 975 | |

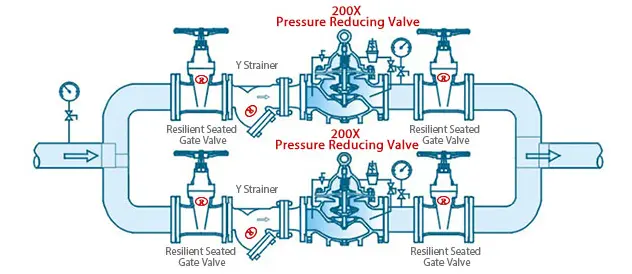

Installation

.jpg?q=80&fm=webp&s=39c97021162866f0f36d957af3de696f)